Application of cyclo olefin copolymer in preparing biological and chemical container

A cyclic olefin and copolymer technology, which is applied in the application field of cyclic olefin copolymer in the preparation of biological and chemical containers, can solve the problems of high cost, low moisture absorption, ordinary glass cannot be sterilized by high-energy radiation, etc. Light, good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

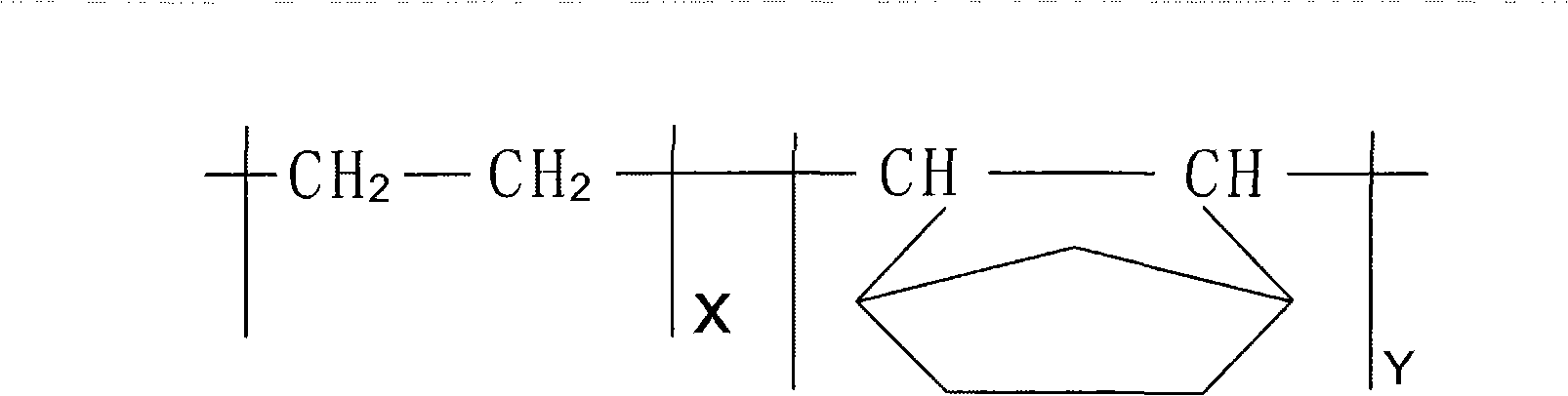

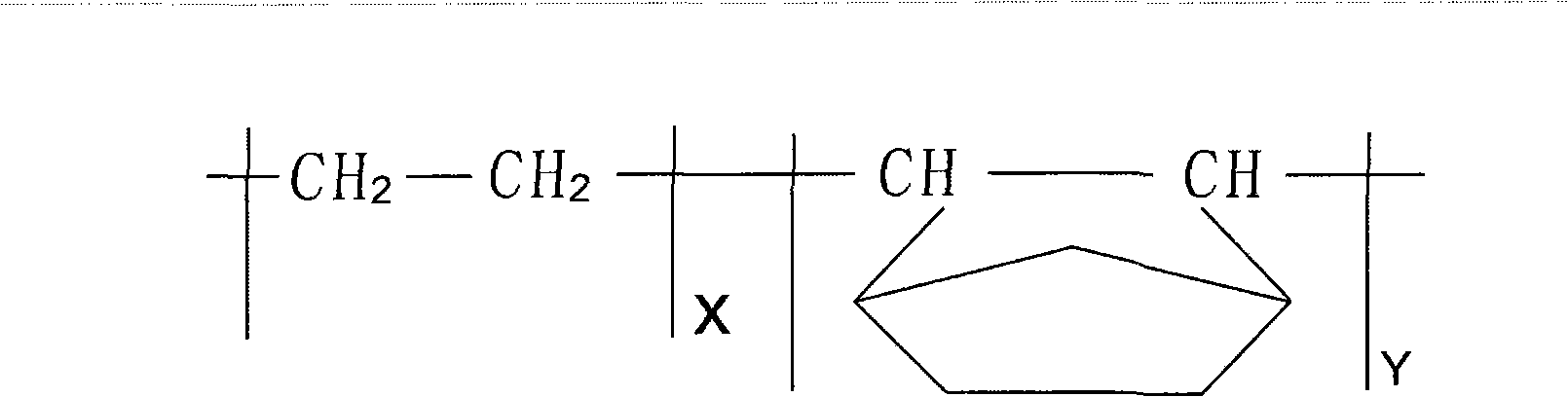

[0029] The cyclic olefin copolymer involved in the present invention is a polymer copolymer obtained by copolymerization of bicycloheptene monomer and ethylene monomer under the action of a catalyst, and its general molecular formula is:

[0030]

[0031] In the formula, the value of X is 400-7000; the value of Y is 400-7000.

[0032] When the above-mentioned cyclic olefin copolymer is applied to the preparation of bacterial culture bottles, such as blood or body cavity fluid bacterial culture bottles. The preparation method is as follows: using cyclic olefin copolymer pellets with a bicycloheptene content of more than 75% (wt / %) and a heat distortion temperature ≥ 127°C, injection molding the tube blank into a tube, and then blow molding the tube blank into a bottle.

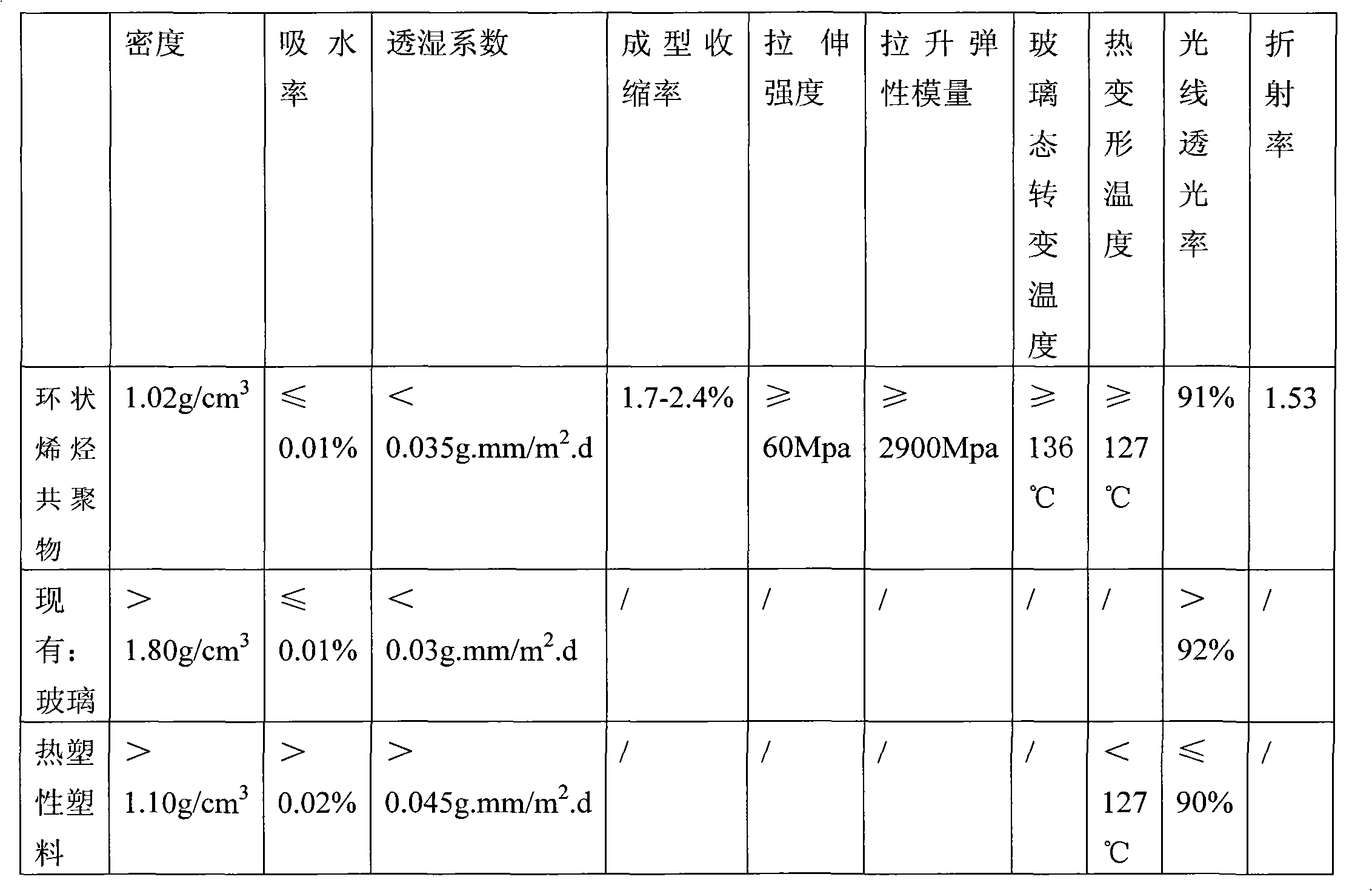

[0033] Can obtain by experiment, adopt the bacterial culture bottle that cyclic olefin copolymer prepares and the comparative performance parameter of existing bacterial culture bottle as shown in the follow...

Embodiment 2

[0037] The difference between this example and Example 1 is that the above-mentioned cyclic olefin copolymer is applied to the preparation of cell culture flasks, such as culture flasks of human or animal tissue cells, insects, and plant tissue cells. The preparation method is as follows: using cyclic olefin copolymer pellets with a bicycloheptene content of more than 75% (wt / %) and a heat distortion temperature ≥ 127°C, injection molding the tube blank into a tube, and then blow molding the tube blank into a bottle.

[0038] It can be obtained through experiments that the comparative performance parameters of the cell culture flask prepared by adopting the cyclic olefin copolymer and the existing cell culture flask are shown in the following table:

[0039]

[0040] It can be seen from the above table that compared with the existing cell culture flasks, the cell culture flasks prepared by using cyclic olefin copolymers can be sterilized by different methods, the flask body ...

Embodiment 3

[0042] The difference between this example and Example 1 is that the above-mentioned cyclic olefin copolymer is applied to the preparation of pharmaceutical packaging bottles, such as liquid medicine and injection medicine packaging bottles. The preparation method is as follows: using cyclic olefin copolymer pellets with a bicycloheptene content of more than 75% (wt / %) and a heat distortion temperature ≥ 127°C, injection molding the tube blank into a tube, and then blow molding the tube blank into a bottle.

[0043] It can be obtained through experiments that the comparative performance parameters of the pharmaceutical packaging bottle prepared by adopting the cyclic olefin copolymer and the existing pharmaceutical packaging bottle are shown in the following table:

[0044]

[0045] It can be seen from the above table that compared with the existing pharmaceutical packaging bottles, the pharmaceutical packaging bottles prepared by using cyclic olefin copolymers have good air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com