Preparation process for synthesizing catalyst for low-carbon olefin by carbon dioxide hydrogenation one-step method

A technology of carbon dioxide and low-carbon olefins, which is applied in the field of preparation of catalysts for the one-step hydrogenation of carbon dioxide to synthesize low-carbon olefins. It can solve the problems of methanol single-pass yield limitation and achieve the effects of equipment reduction, investment reduction and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 (CuO-ZnO-ZrO 2 Catalyst):

[0040] Add 100 grams of deionized water to the three-necked bottle, then place the three-necked bottle in a 95°C constant temperature water bath, and mix 48 grams of 25% copper nitrate solution, 90 grams of 30% zinc nitrate solution, and 48 grams of zirconium oxychloride 30% Solution and 25 grams of 12% urea solution are dripped into the three-necked flask in parallel, and the pH value of the solution is adjusted to about 11 by controlling the drip rate of each solution during the dropwise addition. After the drop is completed, continue to stir for 8 hours. After aging for 5 hours, washing with suction filtration, drying at 110°C for 24 hours, and then roasting at 350°C for 4 hours, CuO-ZnO-ZrO 2 catalyst.

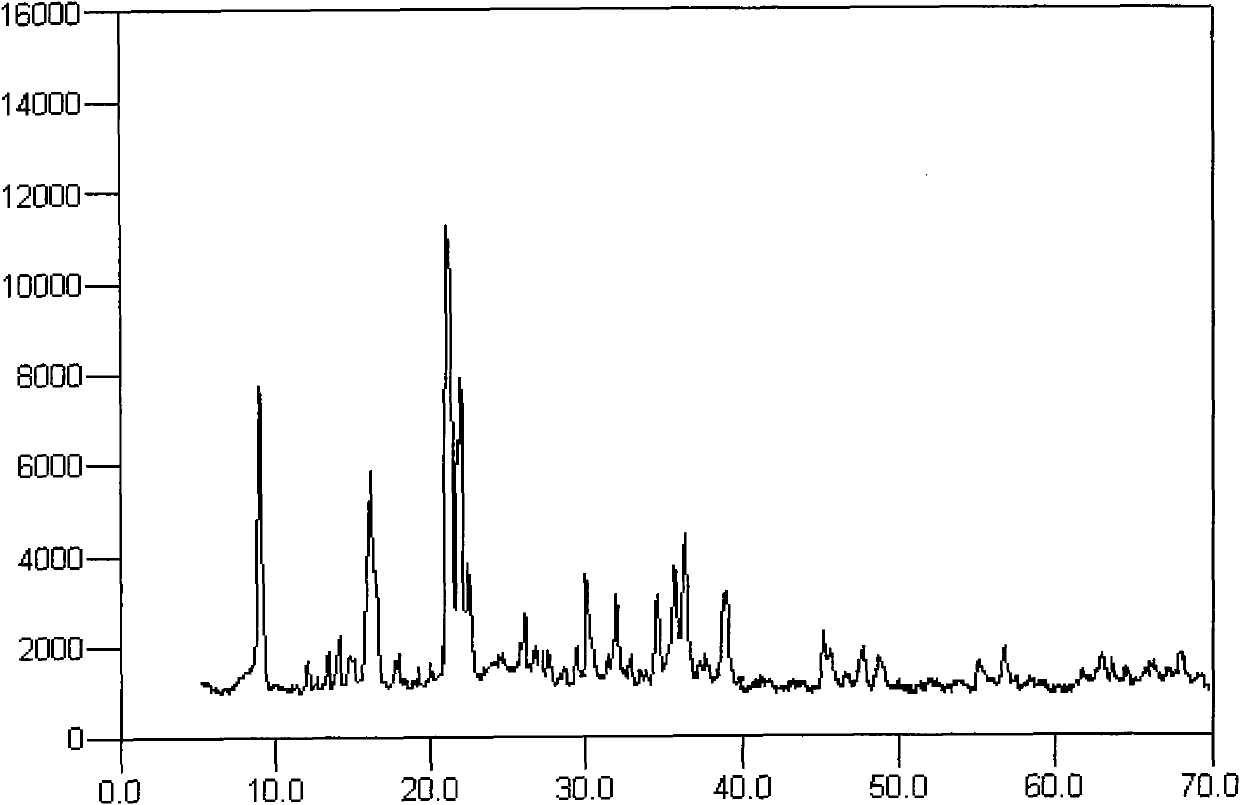

[0041] see figure 1 , as can be seen from the figure, in the composite catalyst CuO-ZnO-ZrO 2 / SBAPO-34 contains CuO (2θ=35.6°, 39.1°, 49.0°), ZnO (2θ=31.8°, 34.5°, 47.5°, 56.7°), ZrO 2 = (36.3°, 62.9°, 68.1°) and SBAPO-...

Embodiment 2

[0046] Take by weighing 5.62 grams of pseudohydroboehmite (containing Al 2 o 3 72.6%) was dissolved in 65 grams of deionized water, 49 grams of 10% phosphoric acid solution was slowly added under stirring, and then 8.54 grams of silica gel (containing SiO 2 28.1%) and 0.98 grams of boron trioxide were added, continued to add 2.5 grams of seed crystal SAPO-34 (directing agent) and 2.65 grams of the prepared CuO-ZnO-ZrO catalyst, finally added 4.04 grams of triethylamine, and continued to stir for 30 minutes , loaded into a reaction kettle, crystallized at 180°C and autogenous pressure for 72 hours, then filtered, washed with deionized water until neutral, then dried in air at 110°C for 24 hours, and calcined at 580°C for 4 hours to obtain CuO-ZnO-ZrO 2 / SBAPO-34 catalyst. The X-ray powder diffraction data of the resulting finished product have attached Figure 1 Characteristics.

[0047] After the catalyst powder is tabletted and pulverized, the 40-60 mesh particles are sc...

Embodiment 3

[0050] Weigh 5.81 grams of pseudohydroboehmite (containing Al 2 o 3 72.6%) was dissolved in 71 grams of deionized water, 54 grams of 10% phosphoric acid solution was slowly added under stirring, and then 8.78 grams of silica gel (containing SiO 2 28.1%) and 1.11 grams of boron trioxide were added, and continued to add 2.5 grams of seed crystal SAPO-34 (directing agent) and the prepared CuO-ZnO-ZrO 2 Catalyst 2.81 grams, finally add 4.15 grams of triethylamine, continue to stir for 30 minutes, put into the reactor, crystallize at 180 ° C and autogenous pressure for 72 hours, then filter, wash with deionized water until neutral, and then in 110 ° C Dry in the air for 24 hours and bake at 580°C for 4 hours to prepare CuO-ZnO-ZrO 2 / SBAPO-34 catalyst. The X-ray powder diffraction data of the resulting finished product have attached Figure 1 Characteristics.

[0051] After the catalyst powder is tabletted and pulverized, the 40-60 mesh particles are screened, and the reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com