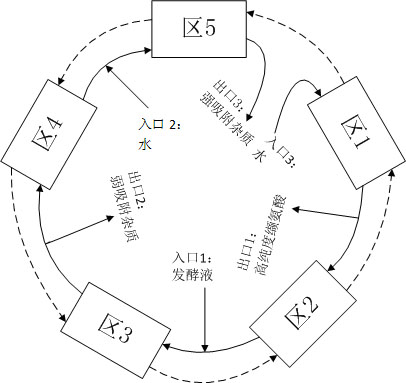

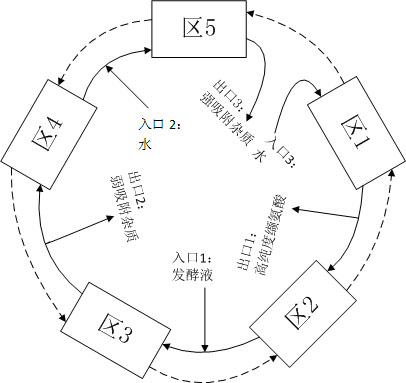

Method for continuously separating and purifying valine in fermentation liquor by using simulated moving bed chromatography

A simulated moving bed and chromatographic separation technology, applied in the field of biological products processing, can solve the problems of long time, reduced separation purity and high cost, and achieve the effects of strong specific adsorption capacity, low production intensity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] After the fermentation, the concentration of valine is about 30g / L, adjust the pH to 2 with hydrochloric acid, centrifuge at 3000 rpm to obtain the supernatant, add 5% of the weight of the supernatant to decolorize with activated carbon, filter to remove the activated carbon, and concentrate the supernatant in vacuum The post-valine concentration was 80g / L. The diameter of the column in the simulated moving bed is 5cm, the number of columns in the 1-5 area is: 2, 2, 2, 2, 2, and the flow velocity in the 1-5 area is 25, 15, 20, 16, 30 cm / min, the system temperature was controlled at 60°C, and the processing volume of the fermentation serum was 98 mL / min. The concentration of the valine product finally obtained from outlet 1 is 32g / L, the purity reaches 99.5%, and the recovery rate is 80%.

Embodiment 2

[0028] After the fermentation, the valine concentration is about 35 g / L, adjust to pH 5 with hydrochloric acid, centrifuge at 8000 rpm to obtain the supernatant, add 10% of the weight of the supernatant to decolorize with activated carbon, filter to remove the activated carbon, and vacuum the supernatant After concentration, the concentration of valine is 70g / L. The diameter of the column in the simulated moving bed is 1 cm, and the number of columns in the 1-5 zone is: 1, 1, 1, 1, 1, and the flow velocity in the 1-5 zone is 30, 22, 27, 18, 50 cm / min, the system temperature was controlled at 80°C, and the processing volume of the fermentation serum was 3.9mL / min. The concentration of the valine product finally obtained from outlet 1 was 32.8 g / L, the purity reached 99.1%, and the recovery rate was 75%.

Embodiment 3

[0030] After the fermentation, the valine concentration is about 20g / L, adjust to pH3 with hydrochloric acid, centrifuge at 10,000 rpm to obtain the supernatant, add 4% of the weight of the supernatant to decolorize with activated carbon, filter to remove the activated carbon, and concentrate the supernatant in vacuum The post-valine concentration was 75g / L. The diameter of the column in the simulated moving bed is 20cm, the number of columns in the 1-5 zone is: 3, 3, 3, 3, 3, and the flow velocity in the 1-5 zone is 35, 25, 32, 16, 40 cm / min, the system temperature was controlled at 20°C, and the processing volume of the fermentation serum was 2.2 L / min. The concentration of the valine product finally obtained from outlet 1 was 37.8 g / L, the purity reached 99.0%, and the recovery rate was 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com