High-temperature heat treatment device under magnetic field and method thereof for preparing bismuth ferrite film

A technology of high-temperature heat treatment and bismuth ferrite, which is applied in the field of high-temperature tube furnace equipment to prepare bismuth ferrite thin films, can solve the problems of affecting ferroelectric polarization, weak magnetic and magnetoelectric coupling effects, and large leakage current, and achieve ferroelectric Improved performance and leakage performance, improved magnetic performance and magnetoelectric coupling performance, and low manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

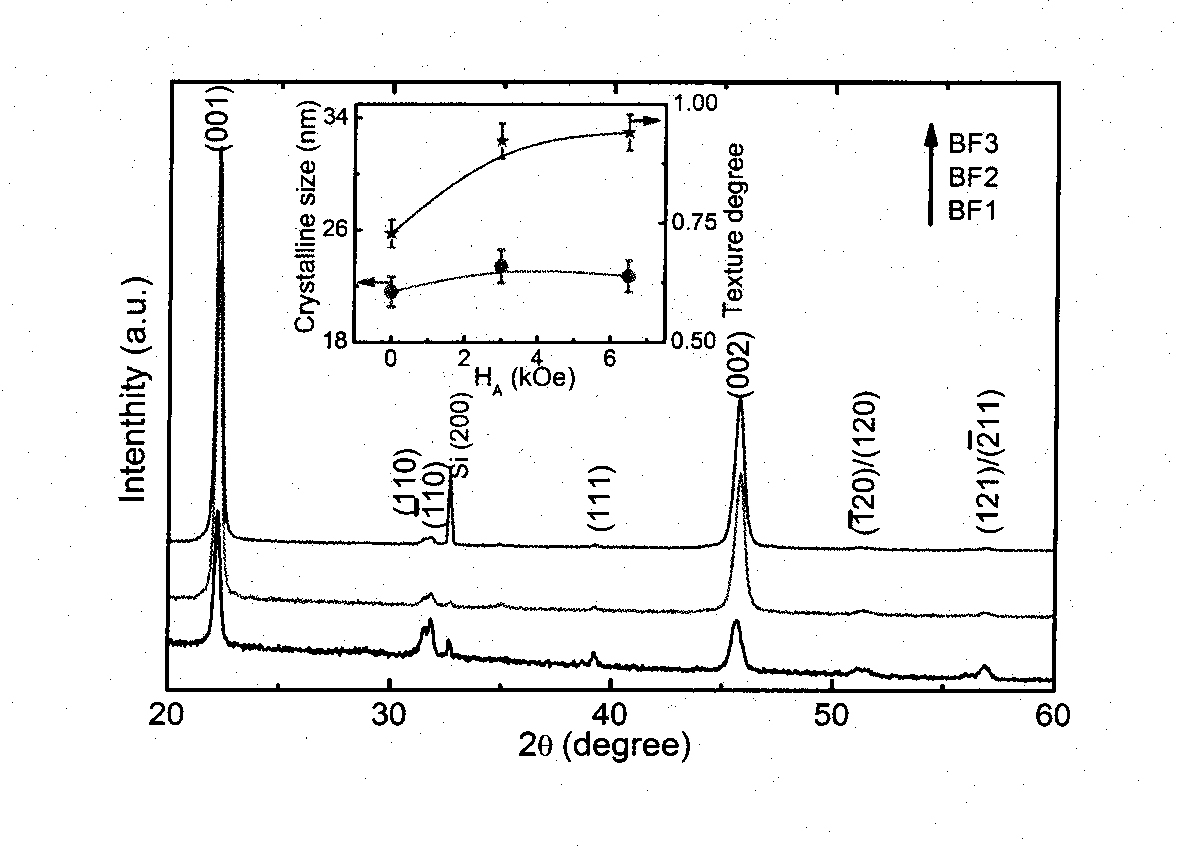

Examples

Embodiment Construction

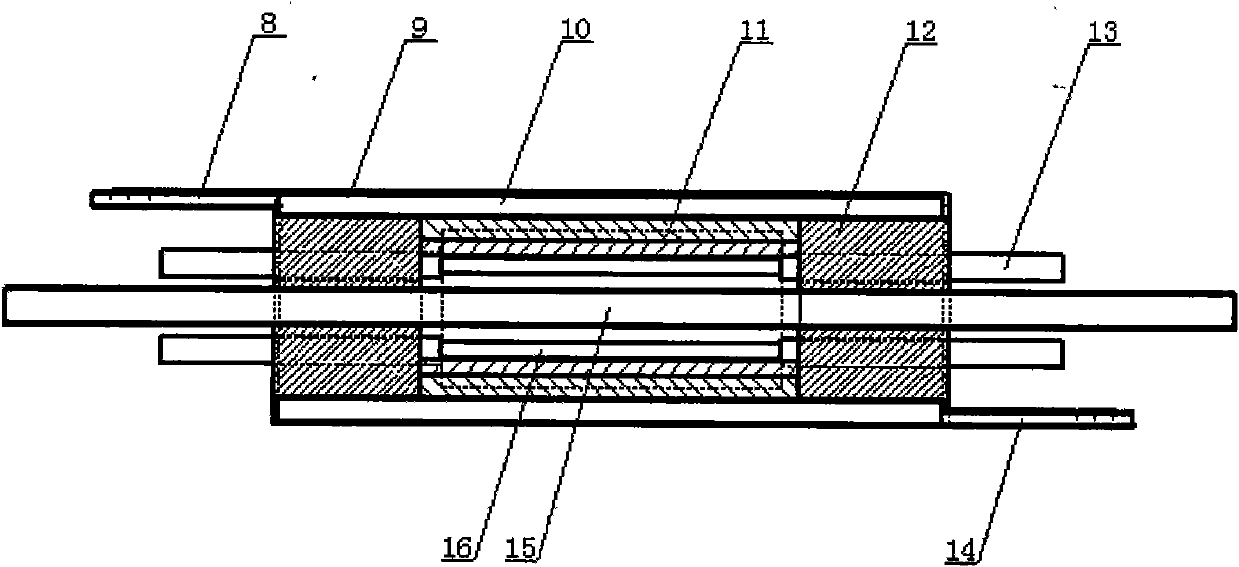

[0034] The device of the present invention will be described in detail below with reference to the drawings.

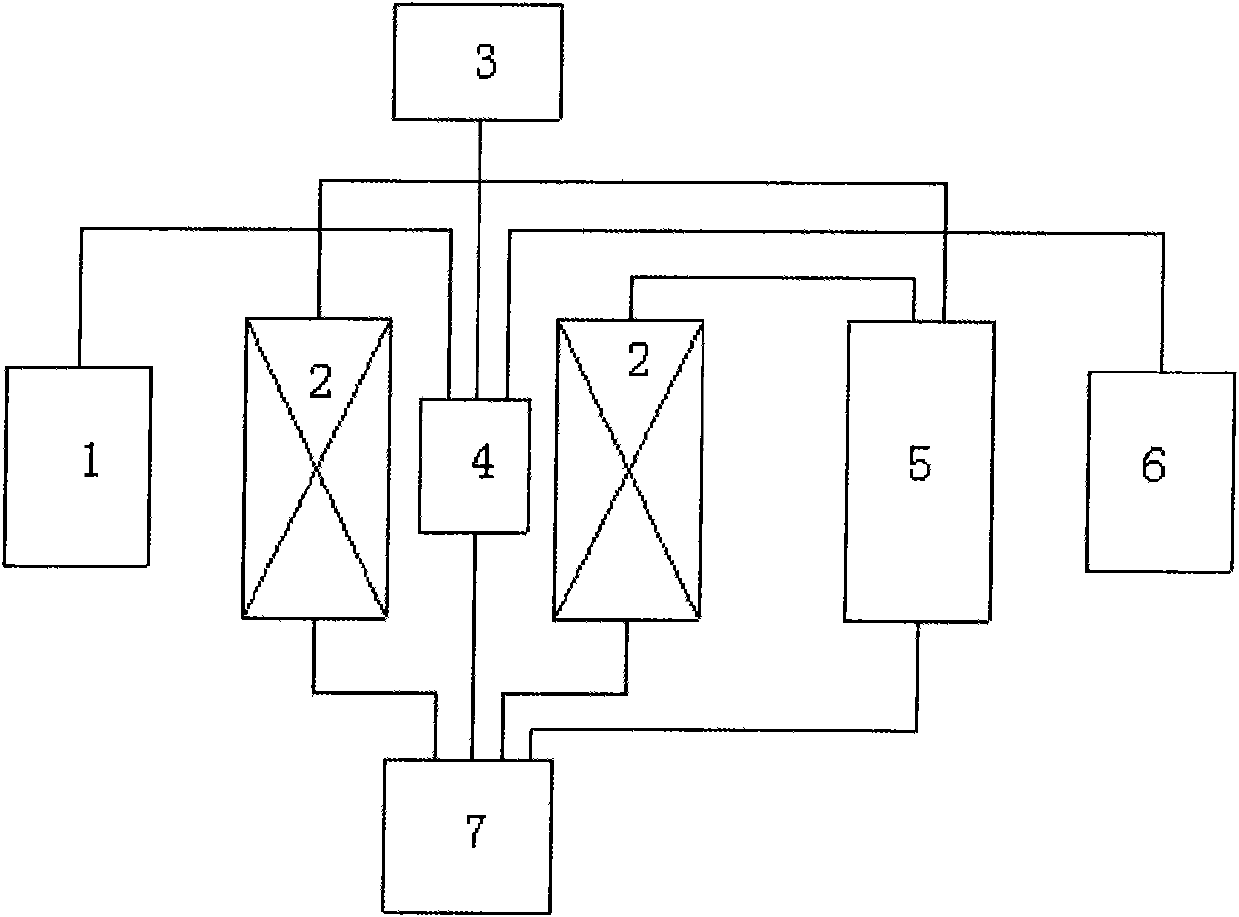

[0035] The composition of the device of the invention is as figure 1 As shown, it is mainly composed of 1, temperature controller, 2, DC water-cooled magnet, 3 vacuum system, 4, tubular heating furnace, 5, DC magnet power supply, 6, atmosphere control system, and 7, circulating cooling water system. The tubular heating furnace 4 is placed between the magnet pole heads of the DC water-cooled magnet 2. The DC water-cooled magnet 2 is connected with a DC magnet power supply 5 and a circulating water cooling system 7, and the heating chamber of the tubular heating furnace 4 is connected with a vacuum The system 3 and the atmosphere control system 6, and the tubular heating furnace 4 is also connected with a temperature controller 1.

[0036] The size of the magnet pole head of the DC water-cooled magnet 2: the diameter is 80~200mm, the maximum adjustment range of the magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com