Method for preparing dye-sensitized solar cell

A solar cell and dye sensitization technology, applied in the field of solar cells, can solve problems such as corrosion, auxiliary electrode corrosion, and insulating layer corrosion, and achieve the effects of strong corrosion resistance, improved adhesion, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

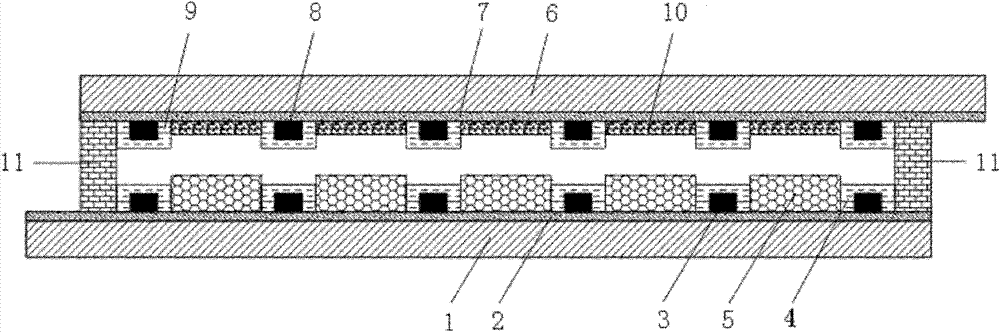

[0023] A preparation method of a dye-sensitized solar cell, the specific preparation method of the cell comprises the following steps:

[0024] Preparation work: punch the conductive glass substrate 6 of the counter electrode according to the position of the graphic design, and then wash the conductive glass substrate 1 of the photoanode and the conductive glass substrate 6 of the counter electrode with detergent, acetone, ethanol, and deionized water in sequence. Ultrasonic cleaning, each cleaning time is 5-20 minutes, after cleaning, dry it with an air gun for later use. The conductive glass substrates 1 and 6 are conductive glass substrates of indium-doped tin oxide or fluorine-doped tin oxide.

[0025] Step 1: On the conductive glass substrate 1 of the photoanode and the conductive glass substrate 6 of the counter electrode, respectively print a layer of silver grid electrodes 3 and 8 by screen printing according to the designed pattern. Then dry it in an oven at 150°C fo...

Embodiment 2

[0035] A preparation method of a dye-sensitized solar cell, the specific preparation method of the cell comprises the following steps:

[0036] Preparations: the same preparations as in Example 1, and will not be repeated here.

[0037] Step 1: On the conductive glass substrate 1 of the photoanode and the conductive glass substrate 6 of the counter electrode, respectively print a layer of silver grid electrodes 3 and 8 by screen printing according to the designed pattern. Then dry it in an oven at 150°C for 20 minutes, and then transfer it to a resistance furnace for sintering at 500°C for 15 minutes. After the furnace temperature is lowered to room temperature, the conductive glass substrate 1 of the photoanode and the conductive glass substrate 6 of the counter electrode are taken out.

[0038] Step 2: Put the conductive glass substrate 1 of the photoanode into the electron beam evaporation chamber, and evaporate a layer of transparent LaB on the silver grid electrode accor...

Embodiment 3

[0047] A preparation method of a dye-sensitized solar cell, the specific preparation method of the cell comprises the following steps:

[0048] Preparations: the same preparations as in Example 1, and will not be repeated here.

[0049] Step 1: On the conductive glass substrate 1 of the photoanode and the conductive glass substrate 6 of the counter electrode, respectively print a layer of silver grid electrodes 3 and 8 by screen printing according to the designed pattern. Then dry it in an oven at 150°C for 20 minutes, and then transfer it to a resistance furnace for sintering at 490°C for 20 minutes. After the furnace temperature is lowered to room temperature, the conductive glass substrate 1 of the photoanode and the conductive glass substrate 6 of the counter electrode are taken out.

[0050] Step 2: Put the conductive glass substrate 1 of the photoanode into the electron beam evaporation chamber, and evaporate a layer of transparent LaB on the silver grid electrode accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com