Method for preparing carboxyl polymeric copper phthalocyanine nanoparticles

A technology of nanoparticles and copper phthalocyanine, which is applied in the field of preparation of carboxyl-polymerized copper phthalocyanine nanoparticles, can solve the problems of unsuitability for industrial production, complex post-treatment process, and difficulty in nano-powder, and achieve controllable particle size and improved Dielectric and motor responsiveness, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) At normal temperature, add 0.05g of carboxyl polymerized copper phthalocyanine (O-CuPc) solid into 20ml of 0.01mol / L sodium hydroxide solution, and stir magnetically until O-CuPc is completely dissolved;

[0025] 2) under mechanical stirring, 0.1g polyethylene glycol monomethyl ether (MPEG, number average molecular weight is 600) is dissolved in the dilute hydrochloric acid of 100ml 0.2mol / L, obtains completely transparent dispersion;

[0026] 3) Place the surfactant dispersion liquid prepared in step 2) in an ice-water bath, and under mechanical stirring conditions, dropwise add the carboxyl polymerized copper phthalocyanine solution prepared in step 1) at a speed of 40ul per 5 seconds, A blue transparent solution is obtained, which is dialyzed in ultrapure water (resistance value 18MΩ) with a dialysis bag until the pH of the dialysate is 7 and does not contain other impurities, to obtain a stable blue transparent colloidal solution;

[0027] 4) After adding 50ml of...

Embodiment 2

[0030] 1) At room temperature, add 0.1 g of carboxyl polymerized copper phthalocyanine (O-CuPc) to 30 ml of 0.005 mol / L sodium hydroxide solution, and stir magnetically until the O-CuPc is completely dissolved;

[0031] 2) under mechanical stirring, 0.15g polyethylene glycol (PEG, number-average molecular weight is 8000) is dissolved in the dilute sulfuric acid of 150ml 1mol / L, obtains completely transparent dispersion liquid;

[0032] 3) with step 3 in embodiment 1);

[0033] 4) After adding 100 ml of acetone to the colloidal solution obtained in step 3) for demulsification, let stand overnight, centrifuge (4000 r / min, 5 min), and then wash three times with acetone, and freeze-dry the washed product, Carboxy-polymerized copper phthalocyanine nanoparticles were obtained.

[0034] The particle size distribution of the carboxyl polymerized copper phthalocyanine nanoparticles measured by transmission electron microscope is: 9-28 nm, and the average particle size is: 17.2 nm.

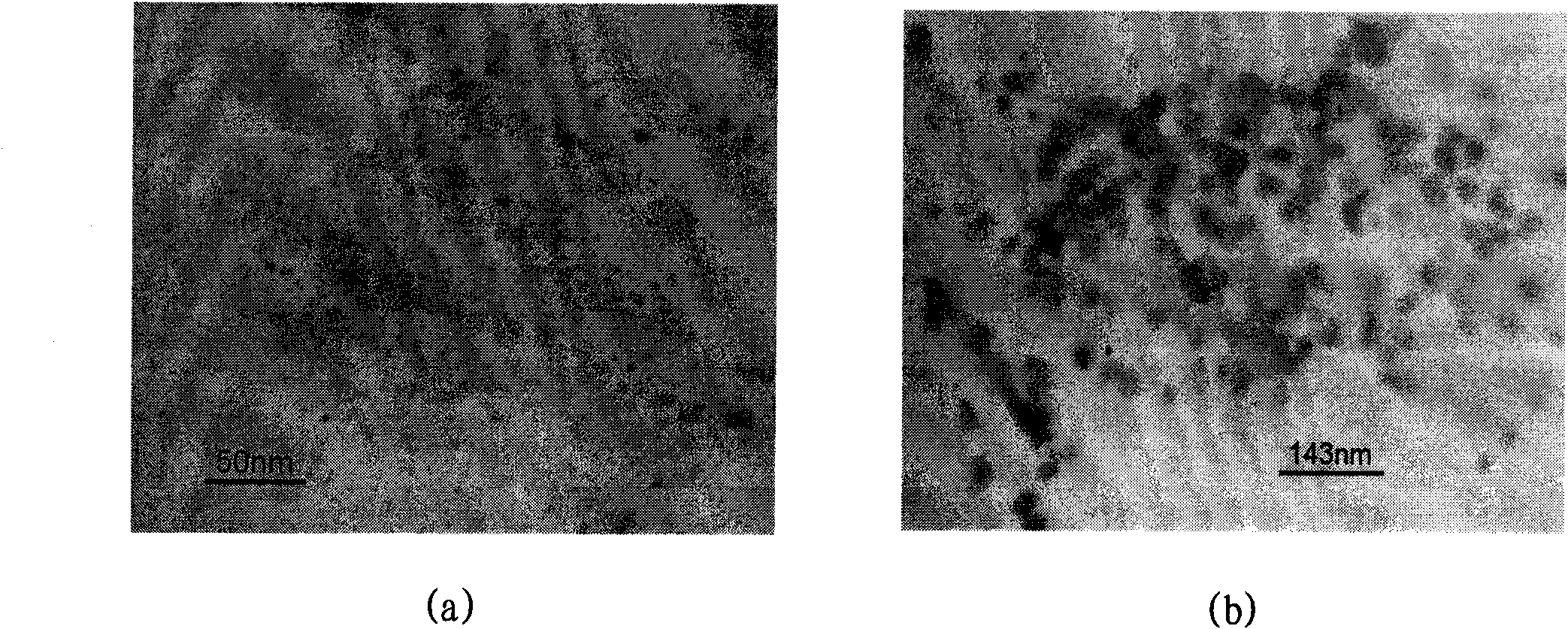

Embodiment 3

[0036] 1) At room temperature, add 0.05g of carboxyl polymerized copper phthalocyanine (O-CuPc) into 20ml of 0.02mol / L sodium hydroxide solution, and stir magnetically until the O-CuPc is completely dissolved;

[0037] 2) under mechanical stirring, 0.1g of cetyltrimethylammonium bromide (CTAB) was dissolved in 100ml of 0.1mol / L dilute hydrochloric acid to obtain a completely transparent dispersion;

[0038] 3) with step 3 in embodiment 1);

[0039] 4) After adding 50 ml of ethanol to the colloidal solution obtained in step 3) for demulsification, let stand overnight, centrifuge (4000 r / min, 5 min), and then wash with acetone 3 times, and freeze-dry the washed product, Carboxy-polymerized copper phthalocyanine nanoparticles were obtained.

[0040] The particle size distribution of the carboxyl polymerized copper phthalocyanine nanoparticles measured by transmission electron microscope is: 15.5-30 nm, and the average particle size is: 25 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com