Plastic wood composite material and preparation method

A technology of plastic-wood composite materials and waste plastics, which is applied in the field of plastic-wood composite materials and its preparation, and achieves obvious economic benefits, low prices, and good molding and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

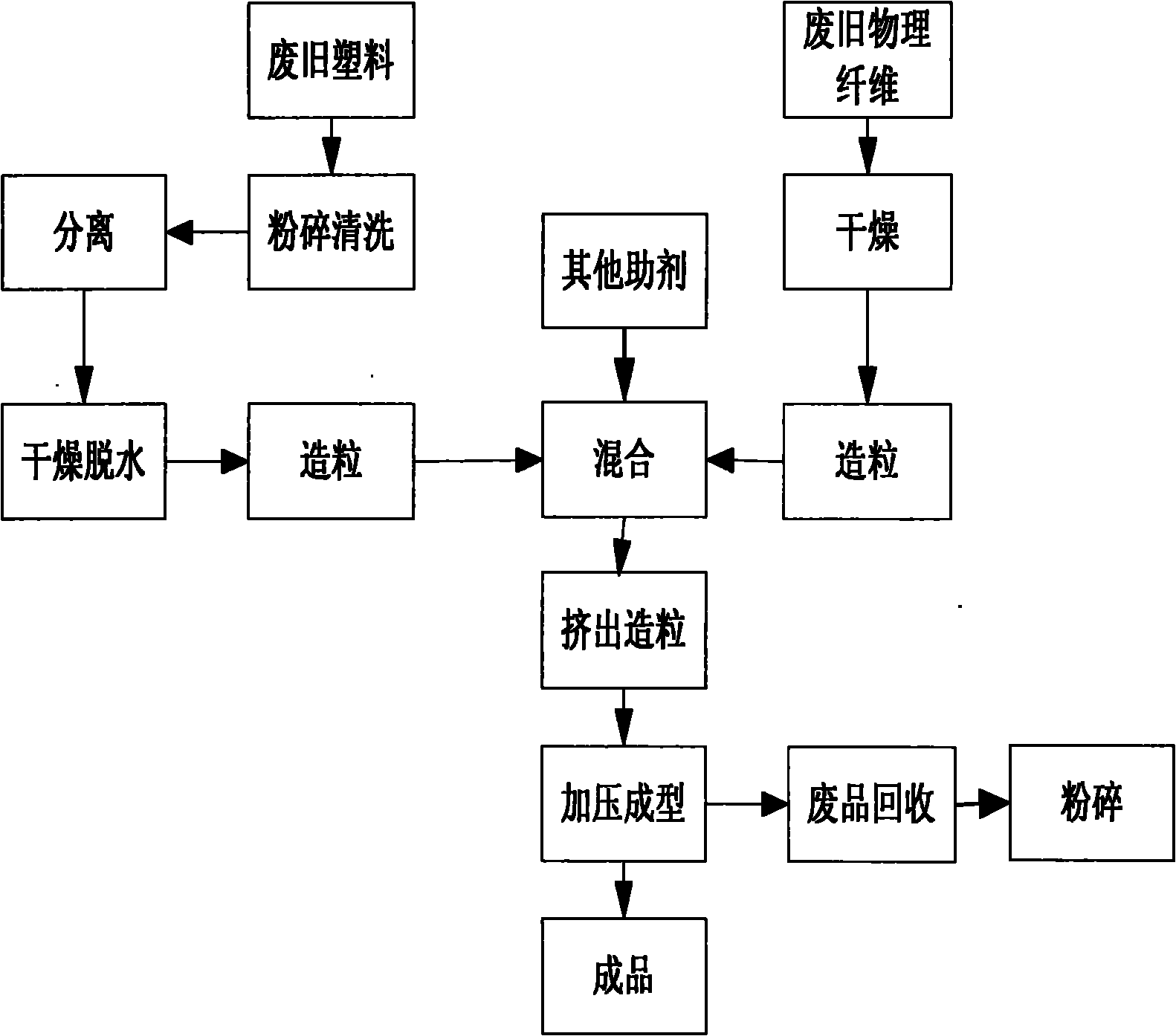

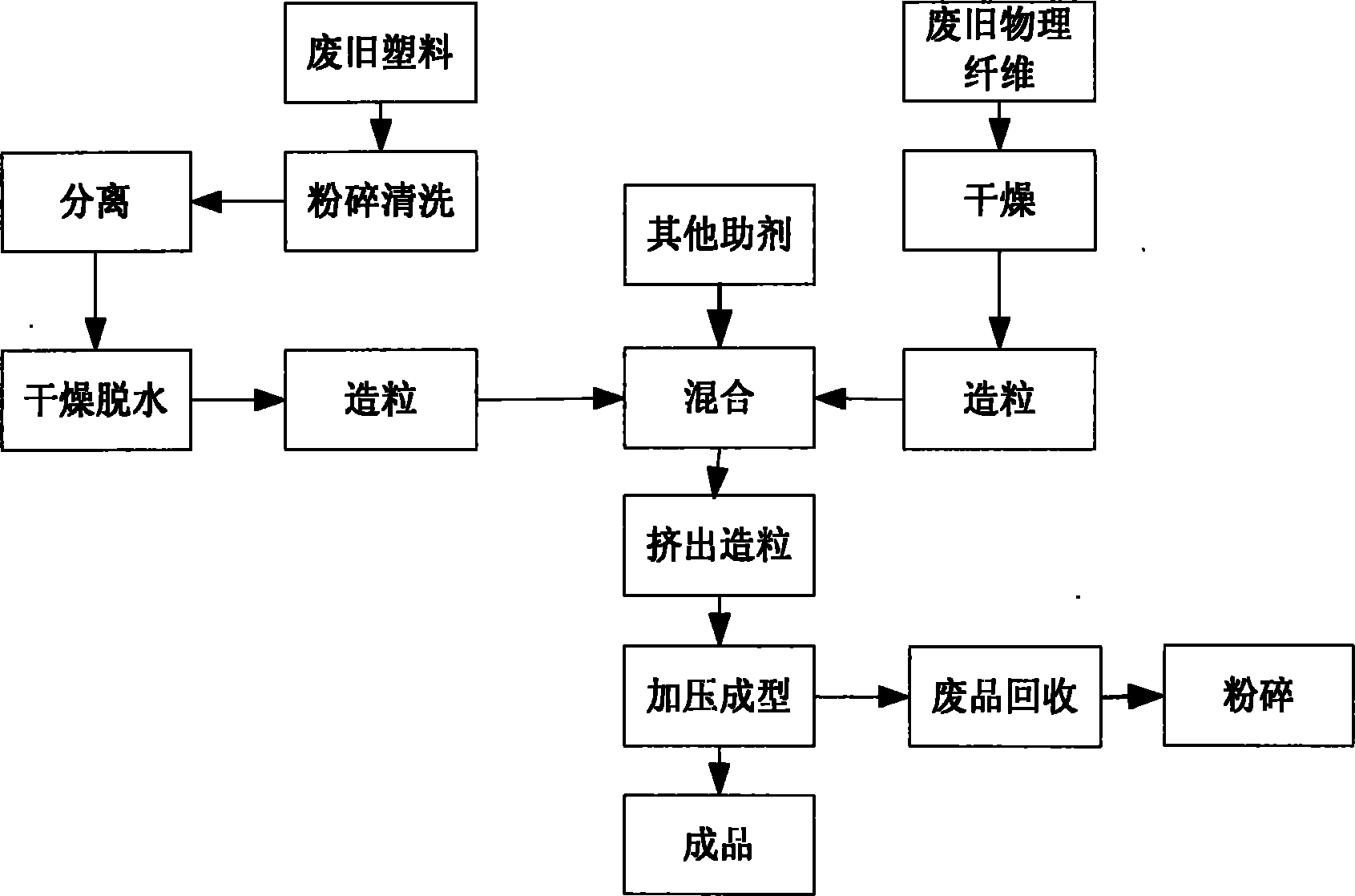

Method used

Image

Examples

Embodiment 1

[0026] 15kg of waste polyvinyl chloride plastic, 70kg of waste sawn wood flour fiber, 1kg of paraffin wax, 1kg of dioctyl phthalate, 2kg of stearic acid, 1kg of titanium dioxide and 5kg of brominated flame retardant.

[0027] 15kg of waste polyvinyl chloride plastic is crushed by a film breaker, then degreased and decontaminated, dried, and then crushed by a crusher again to make granules; 70kg of waste sawn wood powder fibers are passed through a granulator Granulate, dry at 150°C for 3 hours, pass through a 20-30 mesh sieve to obtain granules, and control the moisture content at 1-3%; add waste polyvinyl chloride plastic granules and waste sawn wood powder fiber granules to the mixer for mixing, and add 1kg of paraffin wax, 1kg of dioctyl phthalate, 2kg of stearic acid, 1kg of titanium dioxide and 5kg of bromine-based flame retardant, mechanically stirred and mixed evenly; put the mixture into an extruder and extrude; put the extrudate into a metal mold , press molding, the ...

Embodiment 2

[0029] 30kg of waste polyethylene plastic, 150kg of waste shaving wood flour fiber, 3kg of stearic acid, 3kg of dioctyl phthalate, 5kg of stearic acid, 4kg of titanium dioxide and 15kg of brominated flame retardant.

[0030] 30kg of waste polyethylene plastic is pulverized by a film breaker, then degreased and decontaminated, dried, and then pulverized again by a pulverizer to make granules; 150kg of waste shavings and wood powder fibers are granulated by a granulator , dry at 150°C for 3 hours, pass through a 20-30 mesh sieve to obtain granules, and control the moisture content at 1-3%; add waste polyethylene plastic granules and waste wood shavings and wood flour fiber granules to the mixer and mix them, and add 3kg of stearic acid at the same time , 3kg dioctyl phthalate, 5kg stearic acid, 4kg titanium dioxide and 15kg bromine-based flame retardant, mechanically stirred and mixed evenly; the mixture was added to an extruder for extrusion; the extrudate was put into a metal m...

Embodiment 3

[0032] 50kg of waste polypropylene plastic, 165kg of waste peanut shell fiber, 9kg of calcium stearate, 4kg of dioctyl phthalate, 8kg of chlorinated polyethylene, 5kg of titanium dioxide and 18kg of bromine-based flame retardant.

[0033] 50kg of waste polypropylene plastic is pulverized by a membrane breaker, then degreased and decontaminated, dried, and then pulverized again by a pulverizer to make granules; 165kg of waste peanut shell fibers are granulated by a granulator, Dry at 150°C for 3 hours, pass through a 20-30 mesh sieve to obtain granules, and control the moisture content at 1-3%; add waste polypropylene plastic granules and waste peanut shell fiber granules to a blender and mix, and add 9kg of calcium stearate at the same time, 4kg dioctyl phthalate, 8kg chlorinated polyethylene, 5kg titanium dioxide and 18kg bromine-based flame retardant, mechanically stirred and mixed uniformly; the mixture was added to an extruder for extrusion; the extrudate was put into a met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com