Capacitor substrate structure

A technology of capacitor substrate and dielectric layer, which is used in capacitors, fixed capacitors, components of fixed capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

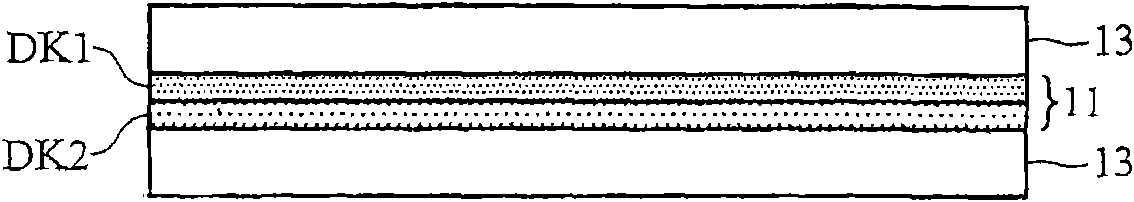

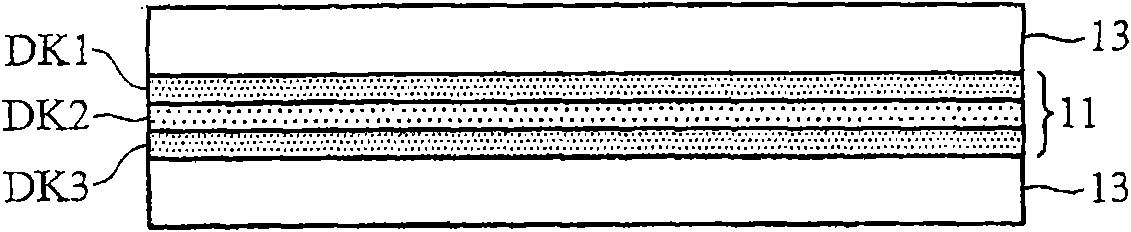

[0029] Such as figure 1 As shown, the capacitive substrate structure of the present invention includes an insulating layer 11 sandwiched between two conductive layers 13 . The thickness of the insulating layer 11 is approximately between 3 μm and 60 μm. If the insulating layer 11 is too thick, it will be difficult to effectively increase the capacitance density; but if the insulating layer 11 is too thin, the adhesion of the dielectric layer to the conductor layer will be poor, and the breakdown voltage will also decrease. The insulating layer 11 is divided into a first dielectric layer DK1 and a second dielectric layer DK2 with a high dielectric constant (at least greater than 45), and the dielectric constant of the second dielectric layer DK2 is higher than that of the first dielectric layer DK1 . In one embodiment of the present invention, the first dielectric layer DK1 includes organic resin. In another embodiment of the present invention, the first dielectric layer DK1 ...

Embodiment 1

[0042] The following is the preparation process of the capacitor substrate of the present invention.

[0043] Take bisphenol-A epoxy resin (bisphenol-Adiglycidyl ether) (188EL, Changchun Resin Company, Taiwan) and tetrabromo bisphenol-A epoxy resin (tetrabromo bisphenol-A diglcidyl ether) of different weights as shown in Table 1 respectively. ether) (BEB-350, Changchun Company, Taiwan), cyclo aliphatic epoxy (HP-7200, DIC, Japan), multifunctional epoxy resin (Multifunctional epoxy), and add 10ml of DMF , heated to 90 ° C ~ 95 ° C to completely dissolve the above resin. Get diamine (diaminodiphenyl sulfone, Diaminodiphenyl sulfone, DDS, available from ACROS, U.S.) of different weights as shown in Table 1 as hardening agent, and boron trifluoride mono-ethylamine (Boron trifluoride mono-ethylamine , BF3-MEA, purchased from ACROS, the United States) as a catalyst, was added to the above epoxy resin solution. After the hardener and catalyst are completely dissolved in the epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com