Method for producing calcium carbonate by using calcium carbide slag and low concentration carbon dioxide-containing waste gas as raw materials

A technology of calcium carbide waste residue and carbon dioxide, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem of difficult to guarantee the permanent storage of carbon dioxide, reduce the investment of fixed assets and operating costs, enhance the operability of industrialization, and improve the carbonization reaction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

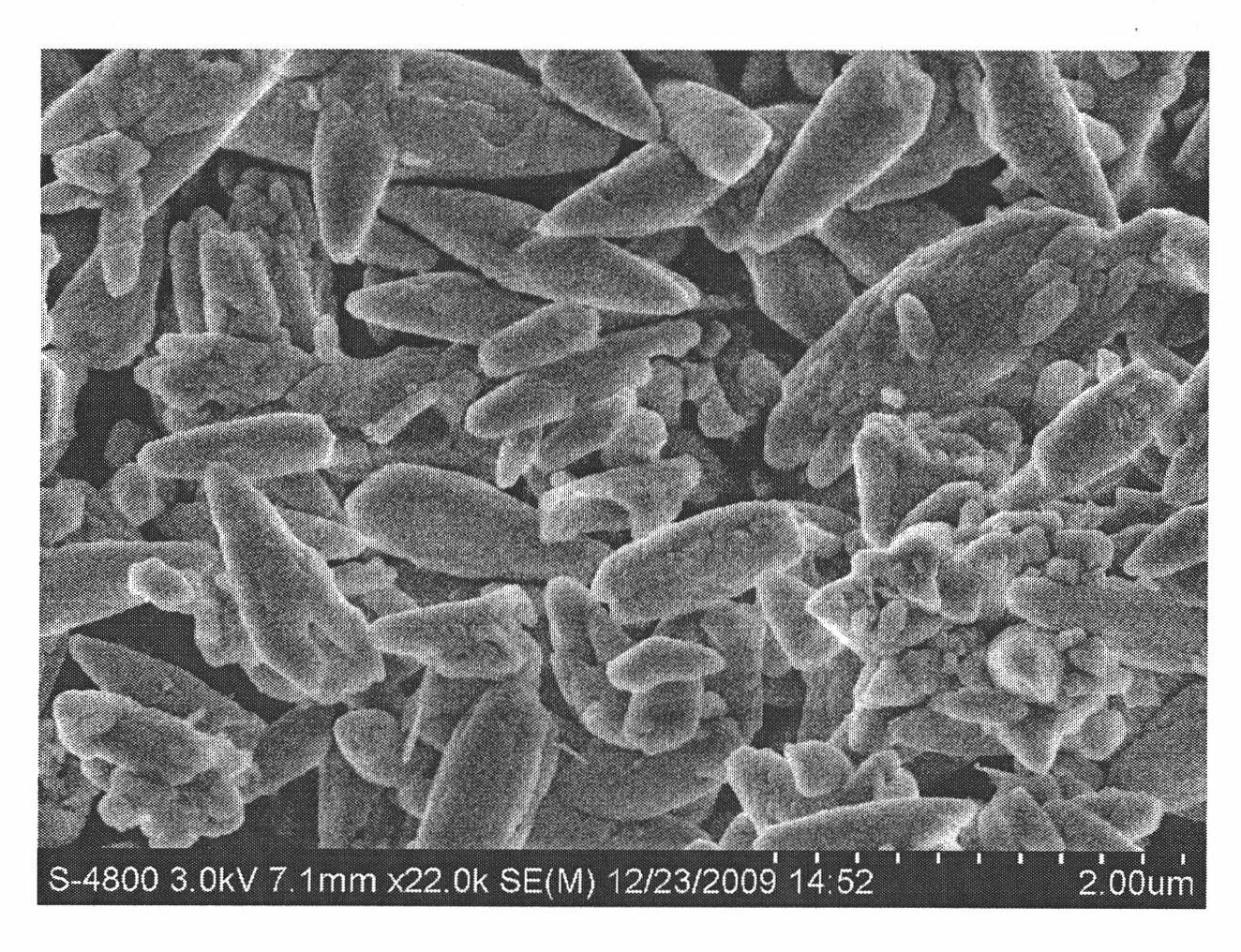

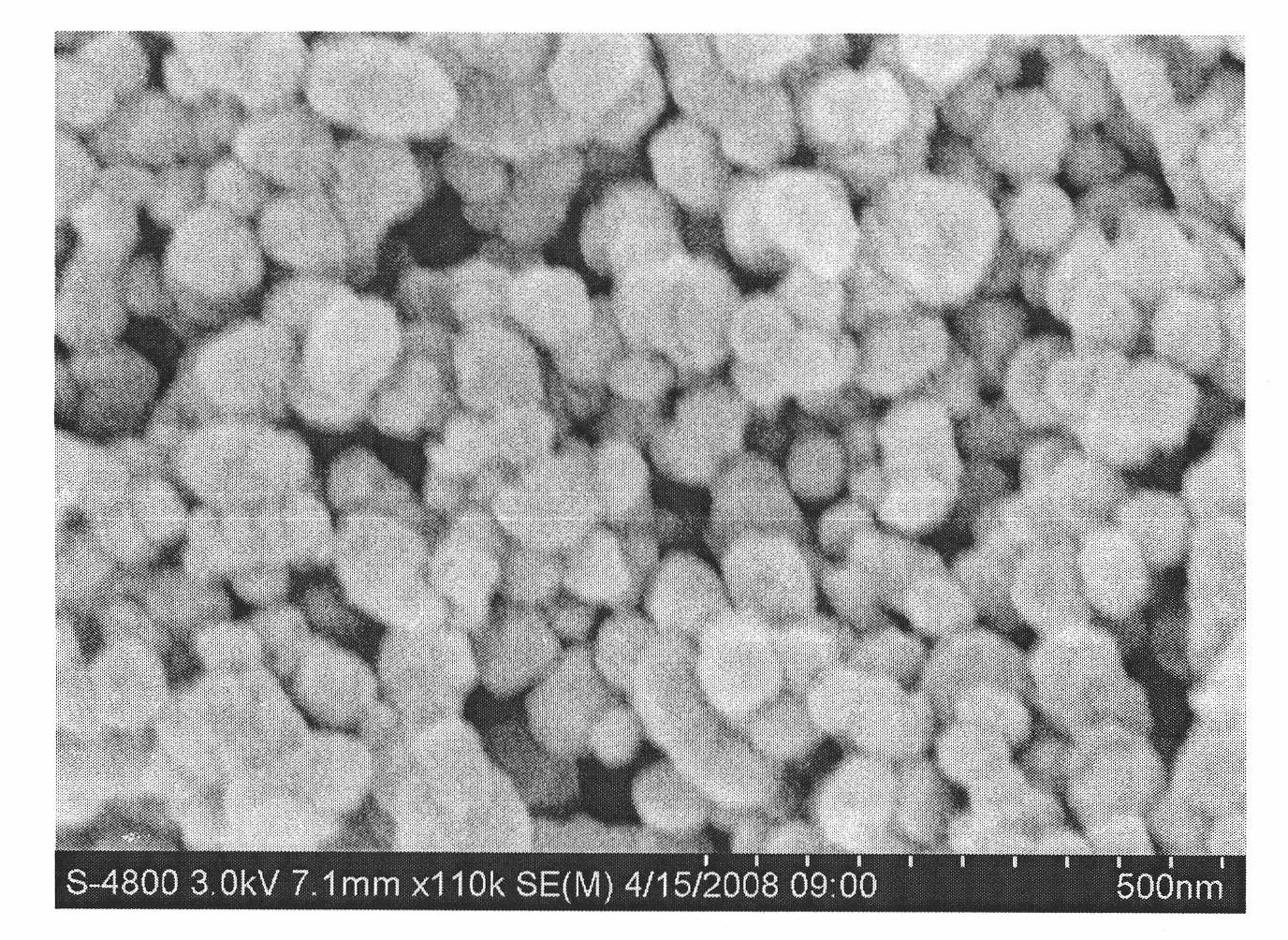

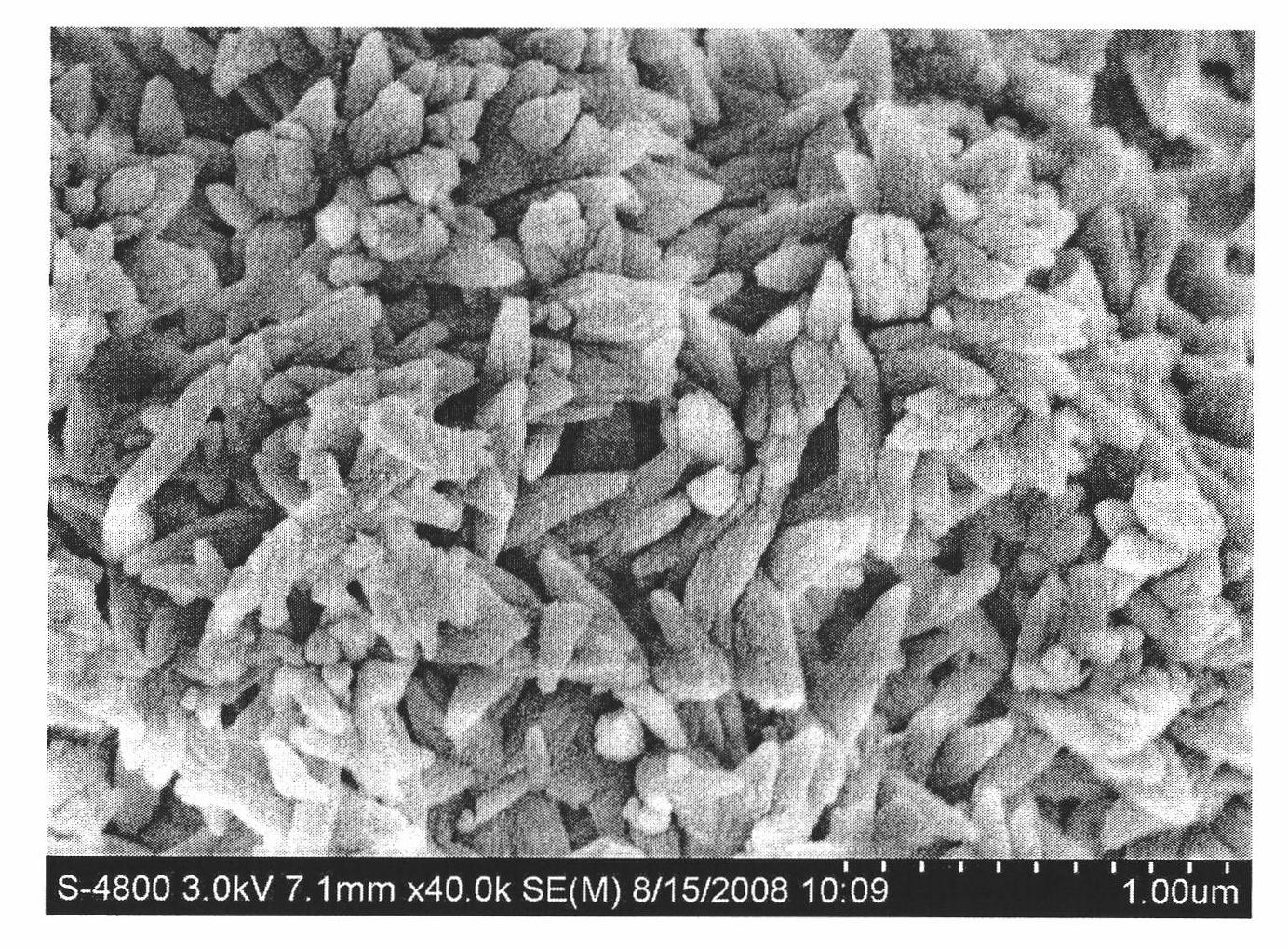

Image

Examples

Embodiment 1

[0043] The calcium carbide waste slag with a water content of less than 30% is fed into the rotary indirect heat exchange dryer at a feed rate of 300kg / h, and is indirect heat exchange with the flue gas from the calciner. The time is 25 minutes, and the moisture content in the solid calcium carbide residue out of the drier is less than 5%. Then, the solid powder of calcium carbide waste slag was sent into a rotary calciner, the calcining temperature was 800° C., and the calcining time was 40 minutes. The heat source for calcination is high-temperature air coal-fired flue gas, and the method of indirect heating is adopted. The temperature of the flue gas exiting the calciner is higher than 200°C, which is used as a heat source in the drying section. After the calcined solid material is cooled, it enters the rotary sealed hot water digester, and the carbonized filtrate obtained by filtering after carbonization is used as part of the digested water, and the digestion reaction ti...

Embodiment 2

[0046] The calcium carbide waste slag with a water content of less than 30% is fed into the rotary indirect heat exchange dryer at a feed rate of 300kg / h, and the indirect heat exchange is performed with the flue gas from the calciner. The operating temperature is 150°C. The time is 30 minutes, and the moisture content in the solid calcium carbide residue out of the drier is less than 5%. Then, the solid powder of calcium carbide waste slag enters the rotary calciner, the calcining temperature is 1000° C., and the calcining time is 30 minutes. The heat source for calcination is natural gas and air combustion gas, and the method of direct contact heating is adopted. The temperature of the flue gas exiting the calciner is higher than 200°C, which is used as a heat source in the drying section. After the calcined solid material is cooled, it enters the rotary sealed hot water digester, and the carbonized filtrate obtained by filtering after carbonization is used as part of the d...

Embodiment 3

[0049] The calcium carbide waste slag with a water content of less than 30% is fed into the rotary indirect heat exchange dryer at a feed rate of 300kg / h, and is indirectly exchanged with the flue gas from the calciner. The operating temperature is 130°C. The time is 40 minutes, and the moisture content in the solid calcium carbide residue out of the drier is less than 5%. Then, the solid powder of calcium carbide waste slag was sent into a rotary calciner, the calcining temperature was 700° C., and the calcining time was 50 minutes. The heat source for calcination is high-temperature air coal-fired flue gas, and the method of indirect heating is adopted. The temperature of the flue gas exiting the calciner is higher than 200°C, which is used as a heat source in the drying section. After the calcined solid material is cooled, it enters the rotary sealed hot water digester, and the carbonized filtrate obtained by filtering after carbonization is used as part of the digested wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com