Preparation method of croscarmellose sodium

A technology of sodium carboxymethyl cellulose and carboxymethyl cellulose is applied in the field of preparation of disintegrant croscarmellose sodium, and achieves the effects of short reaction time, reliable performance and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

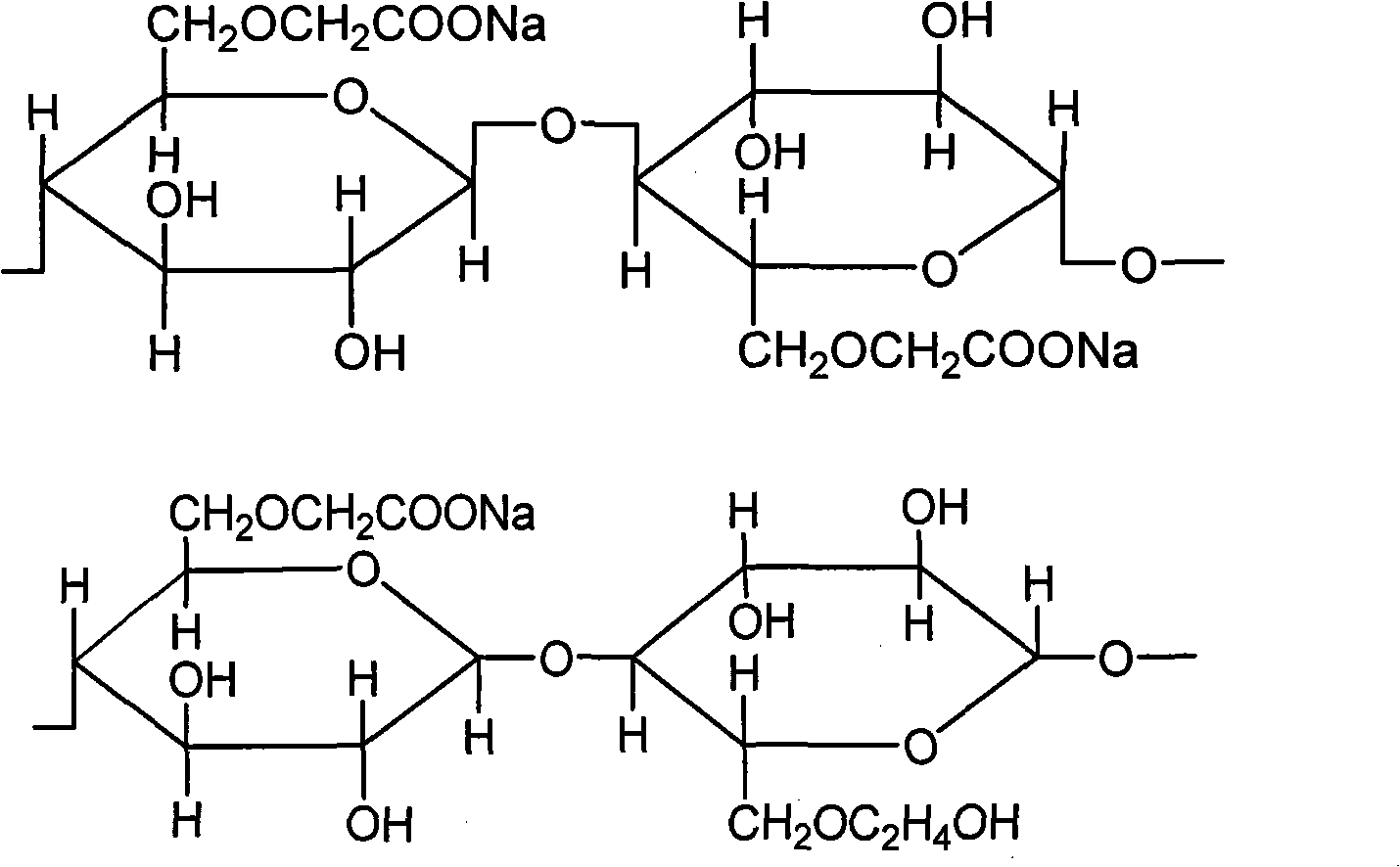

[0036] Dissolve 40 grams of sodium carboxymethylcellulose with 100 grams of organic solvent 1,4-dioxane, stir and dissolve to obtain a homogeneous solution, use sulfuric acid as a catalyst, add a certain amount of sulfuric acid into the sodium carboxymethylcellulose solution, and react The system was acidic, pH = 2.0, reacted at room temperature for 30 minutes to obtain carboxymethyl cellulose; then added 1.5 g of maleic anhydride to the reaction system, reacted at 65°C for 5 hours, the reaction system was weakly acidic, pH = 5, Cool down to room temperature, and process the croscarmellose sodium obtained from the above solution with an alkalized ethanol solvent, which is a homogeneous solution obtained by adding 0.5 g of sodium hydroxide to 100 g of absolute ethanol. Filter, wash with absolute ethanol to pH = 6.5-7.5, and dry at 105°C for 7 hours to obtain croscarmellose sodium powder. The molecular structure of croscarmellose sodium is shown above. Its swelling degree is 15....

Embodiment 2

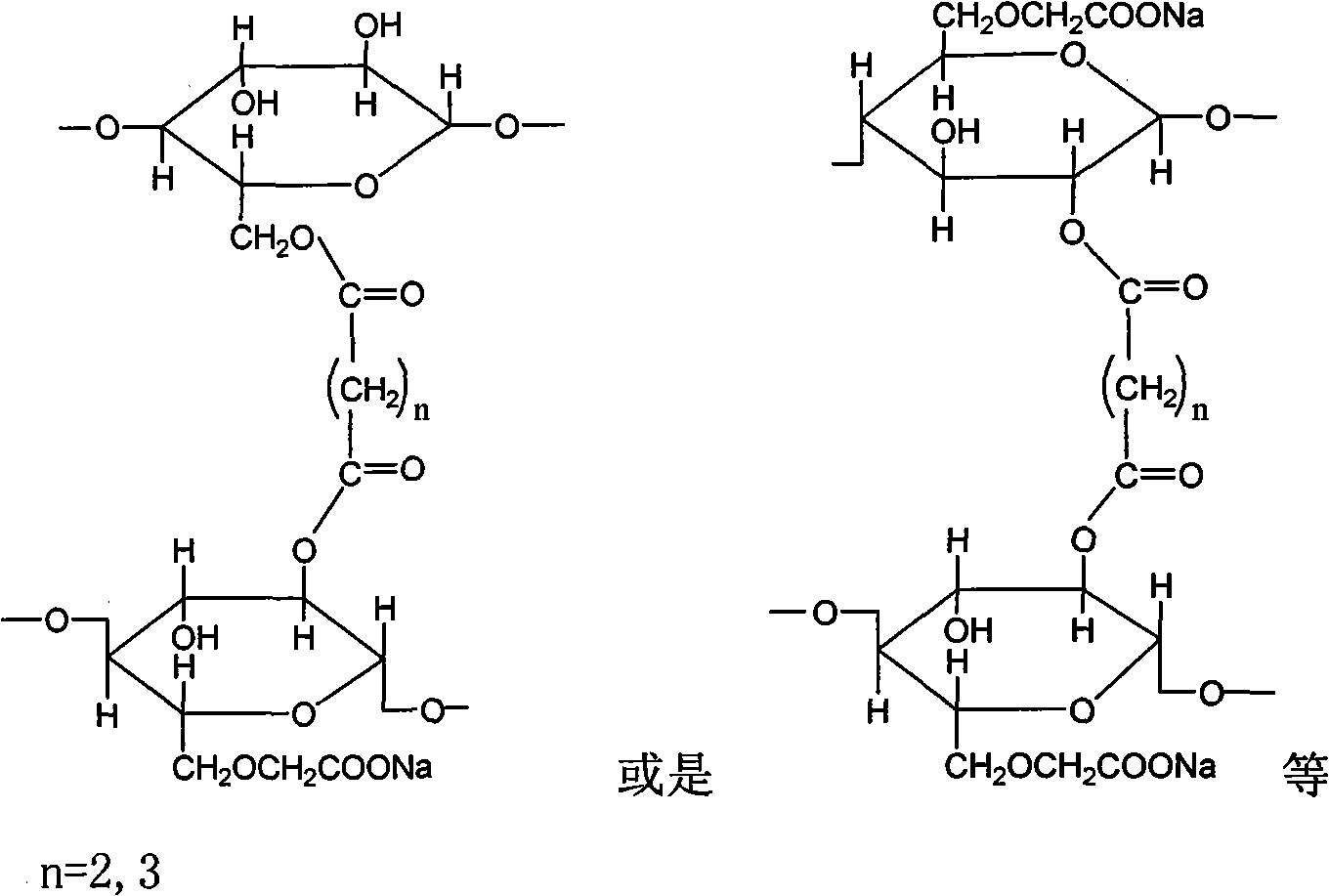

[0044]Dissolve 30 grams of sodium carboxymethyl cellulose with 100 grams of organic solvent tetrahydrofuran, stir and dissolve to obtain a homogeneous solution, use sulfuric acid as a catalyst, add a certain amount of sulfuric acid to the sodium carboxymethyl cellulose solution to make the reaction system acidic, pH=1.0 , reacted at room temperature for 40 minutes to obtain carboxymethyl cellulose; then added 2.5 grams of succinic anhydride to the reaction system, and reacted for 7 hours at 50° C., the reaction system was acidic, pH=3, and the subsequent processing steps were the same as in Example 1, wherein the alkali The ethanol solvent of dehydration is the homogeneous solution that adds 0.6 gram sodium hydroxide to obtain in 100 gram dehydrated alcohols. Its swelling degree is 13. The degree of substitution of sodium carboxymethylcellulose is 0.85.

[0045] Above-mentioned croscarmellose sodium structural formula is as follows:

[0046]

Embodiment 3

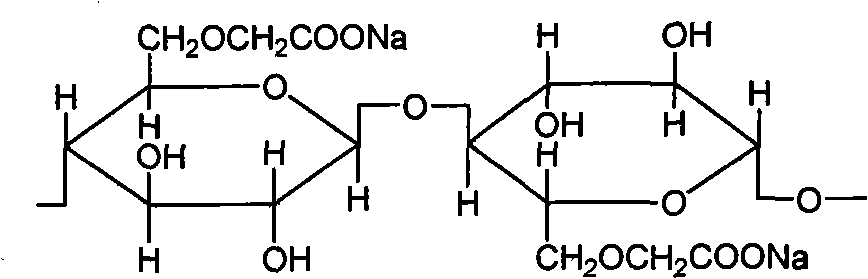

[0048] Dissolve 40 grams of sodium carboxymethylcellulose with 100 grams of organic solvent dimethylformamide, stir and dissolve to obtain a homogeneous solution, use hydrochloric acid as a catalyst, and add a certain amount of hydrochloric acid to the sodium carboxymethylcellulose solution to make the reaction system Acidic, pH = 2.0, react at room temperature for 20 minutes to obtain carboxymethyl cellulose; then add 2 grams of maleic anhydride to the reaction system, react at 60°C for 6 hours, the reaction system is acidic, pH = 2.5, cool down to Room temperature, then use basified ethanol solution (basified ethanol solvent is a homogeneous solution obtained by adding 0.65 gram of sodium hydroxide in 100 gram of absolute ethanol.) Neutralized, filtered and washed with absolute ethanol, and the crude Croscarmellose sodium is dispersed with ethanol solvent and then filtered and washed, and the cross-linked carmellose sodium obtained above is repeatedly dispersed and filtered t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com