Self-propagating brazing heat source medicinal powder, self-propagating brazing device and preparation method thereof

A self-propagating and brazing technology, applied in welding equipment, welding equipment, aluminothermic welding equipment, etc., can solve the problems of incomplete separation of slag, high requirements for operators, poor reaction controllability, etc., and achieve simple heat source powder composition , strong controllability and good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

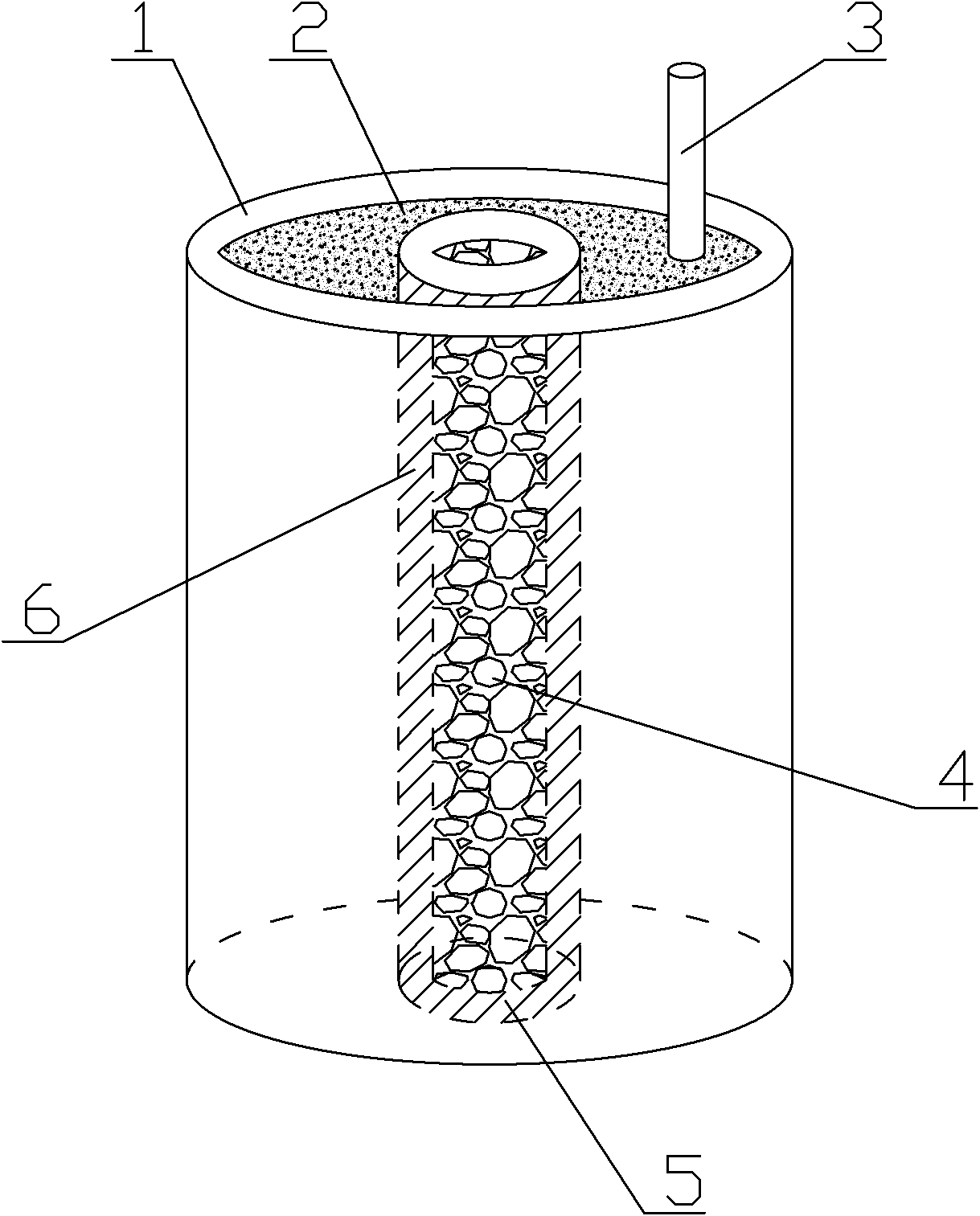

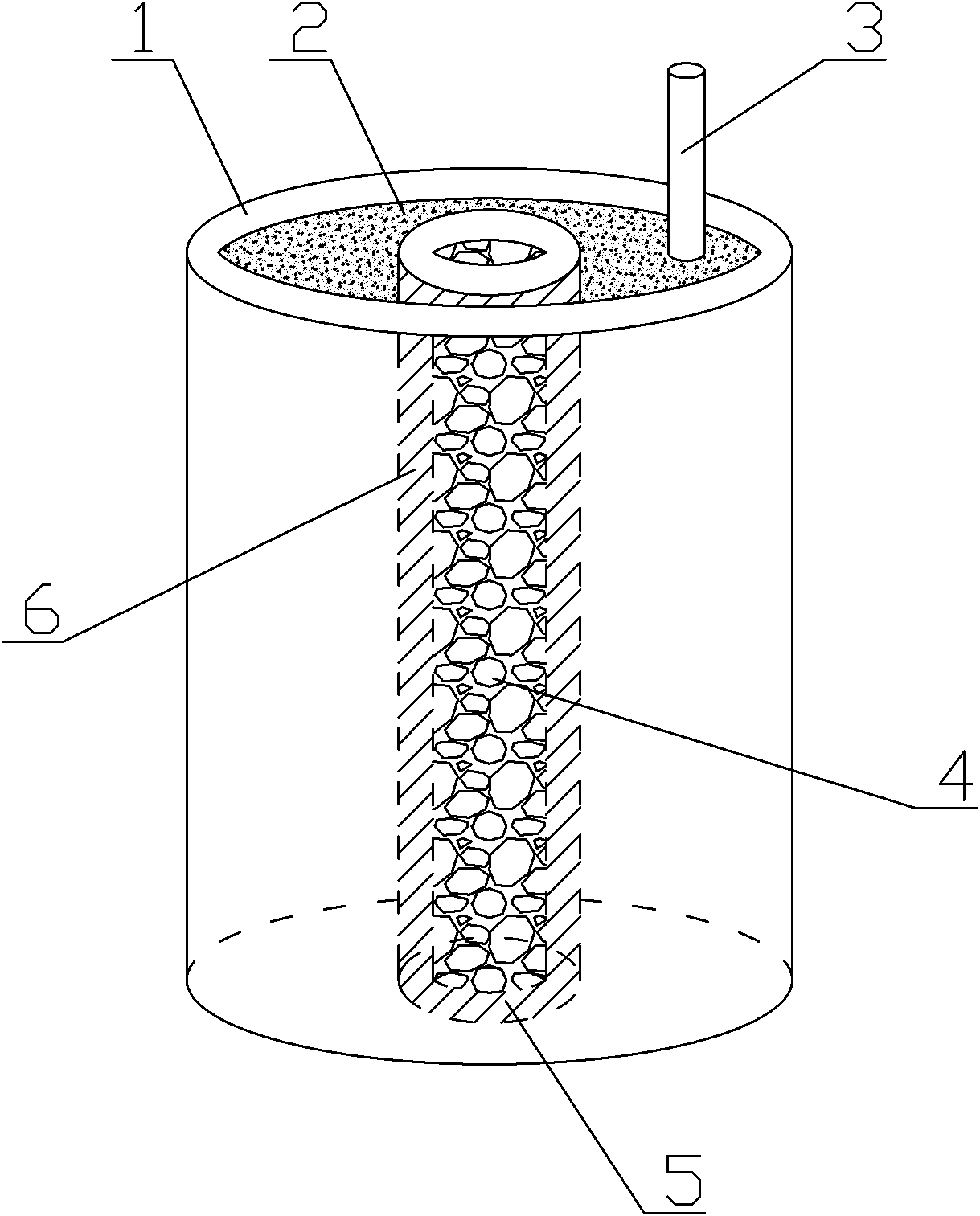

[0032] Weigh Fe according to the following mass percentage 2 o 3 Powder: 20%, Al powder: 30%, CuO powder: 50%, the particle diameters of the three components are similar, and the above raw materials are uniformly ground to obtain the heat source powder 2.

[0033] Fill the heat source medicine powder 2 into the high temperature resistant container 1. The high temperature resistant container 1 has a thickness of 0.5 cm and a through hole 5 in the center of the bottom. It is made of corundum ceramics.

[0034] In the middle of the high-temperature-resistant container 1, put a brazed heat-conducting tank 6 with an opening at the bottom. Between the inner walls of the high-temperature container 1, and the seal does not leak, the thickness of the brazing heat conducting tank 6 is 0.8cm.

[0035] The brazing material 4 is put into the brazing heat conduction tank 6 .

[0036] A magnesium strip is inserted into the heat source powder as a lead wire.

[0037] Weld the 2.5mm thick ...

Embodiment 2

[0040] Weigh Fe according to the following mass percentage 2 o 3 Powder: 32%, Al powder: 20%, CuO powder: 48%, the particle size of the three components is uniform, and the raw materials are ground uniformly to obtain the heat source drug powder 2.

[0041] Fill the heat source drug powder 2 into the high temperature resistant container 1. The high temperature resistant container 1 has a thickness of 2 cm and a through hole 5 in the center of the bottom.

[0042] In the middle of the high-temperature-resistant container 1, put a brazed heat-conducting tank 6 with an opening at the bottom. Between the inner walls of the high-temperature container 1, and the seal does not leak, the thickness of the brazing heat conducting tank 6 is 2cm.

[0043] The brazing material 4 is put into the brazing heat conduction tank 6 .

[0044] A magnesium strip is inserted into the heat source powder as a lead wire.

[0045] Weld the 2mm thick steel plate, place the above self-propagating braz...

Embodiment 3

[0048] Weigh Fe according to the following mass percentage 2 o 3 Powder: 38%, Al powder: 22%, CuO powder: 40%, the particle size of the three components is uniform, and the raw materials are ground uniformly to obtain the heat source drug powder 2.

[0049]Fill the heat source drug powder 2 into the high temperature resistant container 1. The high temperature resistant container 1 has a thickness of 1.2 cm and a through hole 5 in the center of the bottom. It is made of magnesium oxide ceramics. The heat resistant temperature of the magnesium oxide ceramics is generally 1600°C.

[0050] In the middle of the high-temperature-resistant container 1, put a brazed heat-conducting tank 6 with an opening at the bottom. Between the inner walls of the high-temperature container 1, and the seal does not leak, the thickness of the brazing heat conducting tank 6 is 1.5cm.

[0051] The brazing material 4 is put into the brazing heat conduction tank 6 .

[0052] A magnesium strip is inser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com