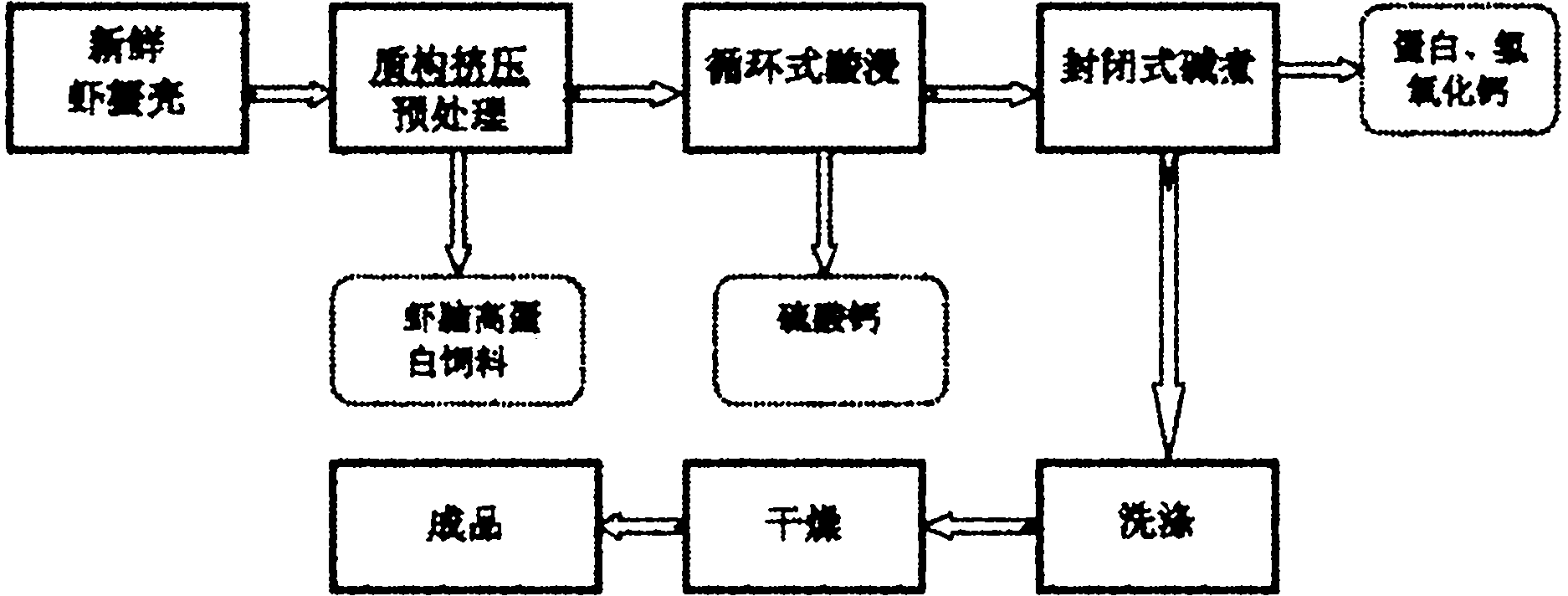

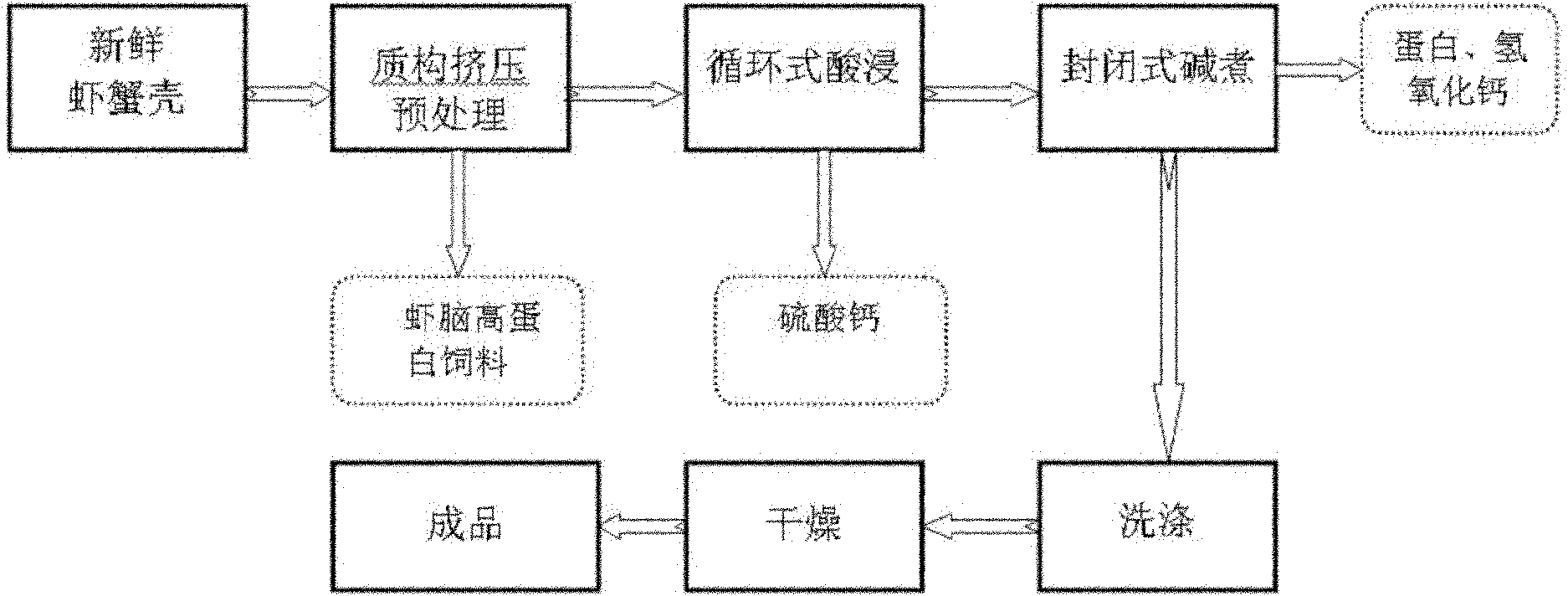

Chitin clean production process

A clean production and chitin technology, applied in the field of chitin clean production process, can solve the problems of resource waste and chitin production process pollution, and achieve the effects of reducing acid and alkali consumption, improving the factory environment, and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 1,000 kg of fresh crayfish shells to the texture extrusion device for texture extrusion pretreatment; add the texture extrusion pretreated crayfish shells to the texture extrusion pretreated crayfish shells with a weight ratio of 1 The concentration of :10 is 6wt% hydrochloric acid to carry out circulation immersion (replenish acid according to consumption in the circulation immersion process, make the hydrochloric acid concentration that is used for immersion remain on 6wt%), immersion time is 12h. During the dynamic cycle pickling process, the acid solution is recycled up to 6 times, so that the calcium content in the wastewater tends to be saturated; the wastewater is added with sulfuric acid, filtered to obtain calcium sulfate, and the acidic wastewater is recycled to prepare the acid solution for cyclic soaking. The crayfish shells soaked in acid are washed with water (preferably until neutral).

[0030] The crayfish shells after the pickling treatment and clea...

Embodiment 2

[0035] Add 1,000 kg of fresh crab shells to the texture extrusion device for texture extrusion pretreatment; add the texture extrusion pretreated crab shells to the texture extrusion pretreated crab shells with a weight ratio of 1:8 Hydrochloric acid with a concentration of 8wt% was used for cyclic immersion (acid replenishment was performed according to consumption during cyclic immersion, so that the concentration of hydrochloric acid used for immersion was maintained at 8wt%), and the immersion time was 15 hours. During the dynamic cycle pickling process, the acid solution is recycled up to 5 times, so that the calcium content in the wastewater tends to be saturated; the wastewater is added with sulfuric acid, filtered to obtain calcium sulfate, and the acidic wastewater is recycled to prepare the acid solution for cyclic soaking. The crab shell after acid soaking is washed with water (preferably washed to neutrality).

[0036] The crab shells after pickling treatment and c...

Embodiment 3

[0041] Add 1,000 kg of fresh Rochester shrimp shells to the texture extrusion device for texture extrusion pretreatment; add the texture extrusion pretreated Roche shrimp shells to the texture extrusion pretreated Roche shrimp shells with a weight ratio of 1 The concentration of : 12 is that the hydrochloric acid of 5wt% carries out cyclic soaking (replenishes acid according to consumption in the cyclic soaking process, makes the concentration of hydrochloric acid used for soaking remain on 5wt%), soaking time is 10h. During the dynamic cycle pickling process, the acid solution is recycled up to 8 times, so that the calcium content in the wastewater tends to be saturated; the wastewater is added with sulfuric acid, filtered to obtain calcium sulfate, and the acidic wastewater is recycled to prepare the acid solution for cyclic soaking. The Roche shrimp shells soaked in acid are washed with water (preferably until neutral).

[0042] The Roche shrimp shells after the pickling tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com