Electrochemical sensor for field trace heavy metal detection

A trace heavy metal, electrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of unstable detection signal, poor reproducibility, limited application, etc., to achieve rapid detection, easy operation, reproducibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

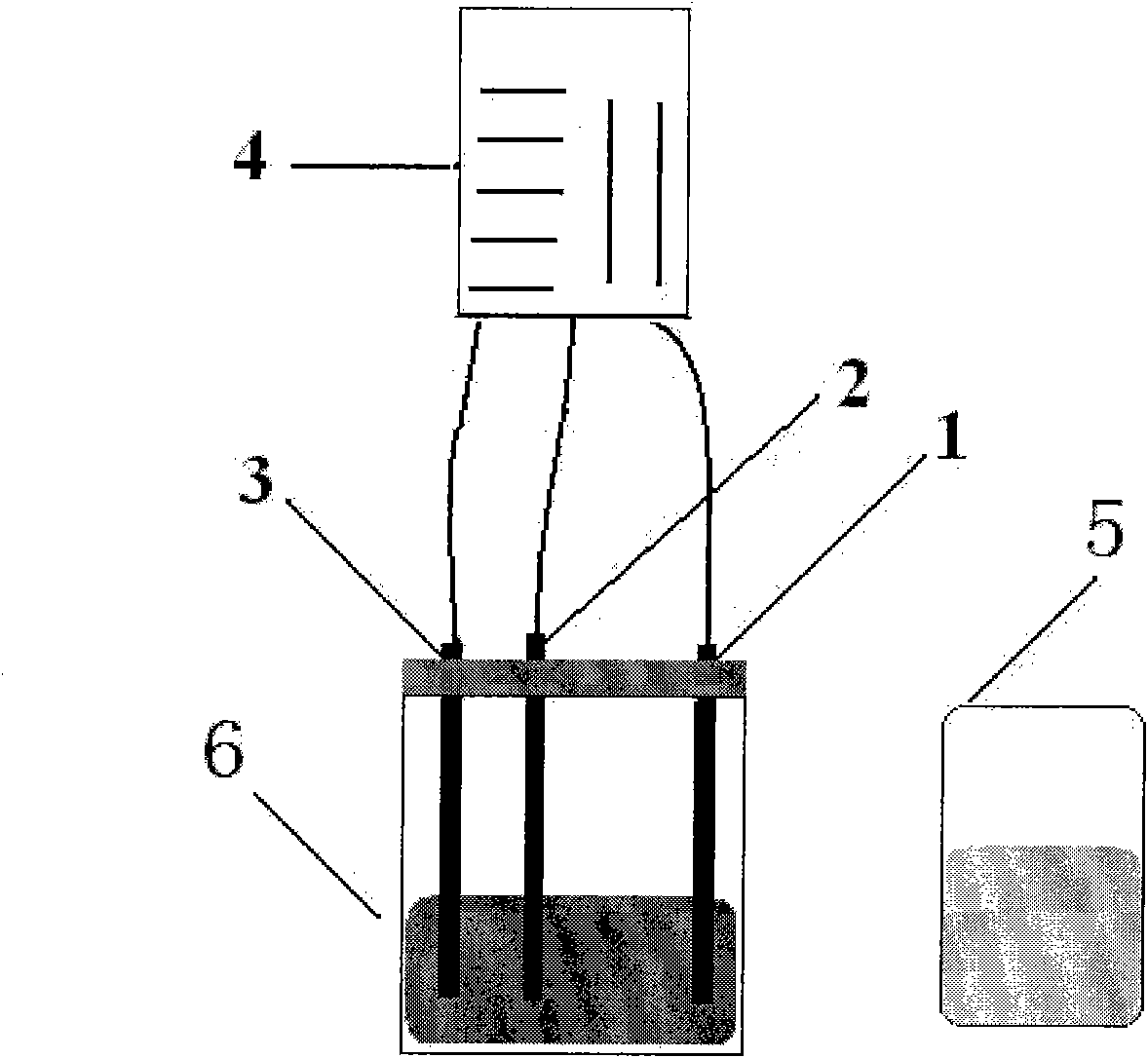

[0021] The sensor includes a working electrode, a reference electrode, an auxiliary electrode, an electroplating solution and a detection solution. The working electrode 1, the auxiliary electrode 2 and the reference electrode 3 are respectively connected to the control potentiometer 4 through wires; the three electrodes are inserted into the detection solution 6 for use . The schematic diagram of the sensor is as figure 1 shown.

[0022] The working electrode 1 needs to be coated with the electroplating solution 5 before detection; the electroplating solution is a mixed solution containing bismuth nitrate, wherein the concentration of bismuth in the mixed solution is 0.05-1.5 mg / L, and the pH value is 2-5.

[0023] The working electrode can be carbon, gold, platinum, aluminum, copper, iron, indium, tungsten or conductive ITO electrode; the reference electrode can be saturated calomel electrode, silver / silver chloride electrode or double junction electrode; the auxiliary elec...

Embodiment 2

[0025] The working electrode is a platinum electrode, and the detection solution is a mixture of bismuth nitrate and perchloric acid, wherein the concentration of bismuth is 1.2mg / L, and the pH value of the solution is 2; the electroplating solution is a mixture of bismuth nitrate and citrate buffer solution, wherein The bismuth concentration is 0.8mg / L, and the pH value of the solution is 4. The citrate buffer solution is a mixed solution of citric acid and sodium dihydrogen phosphate.

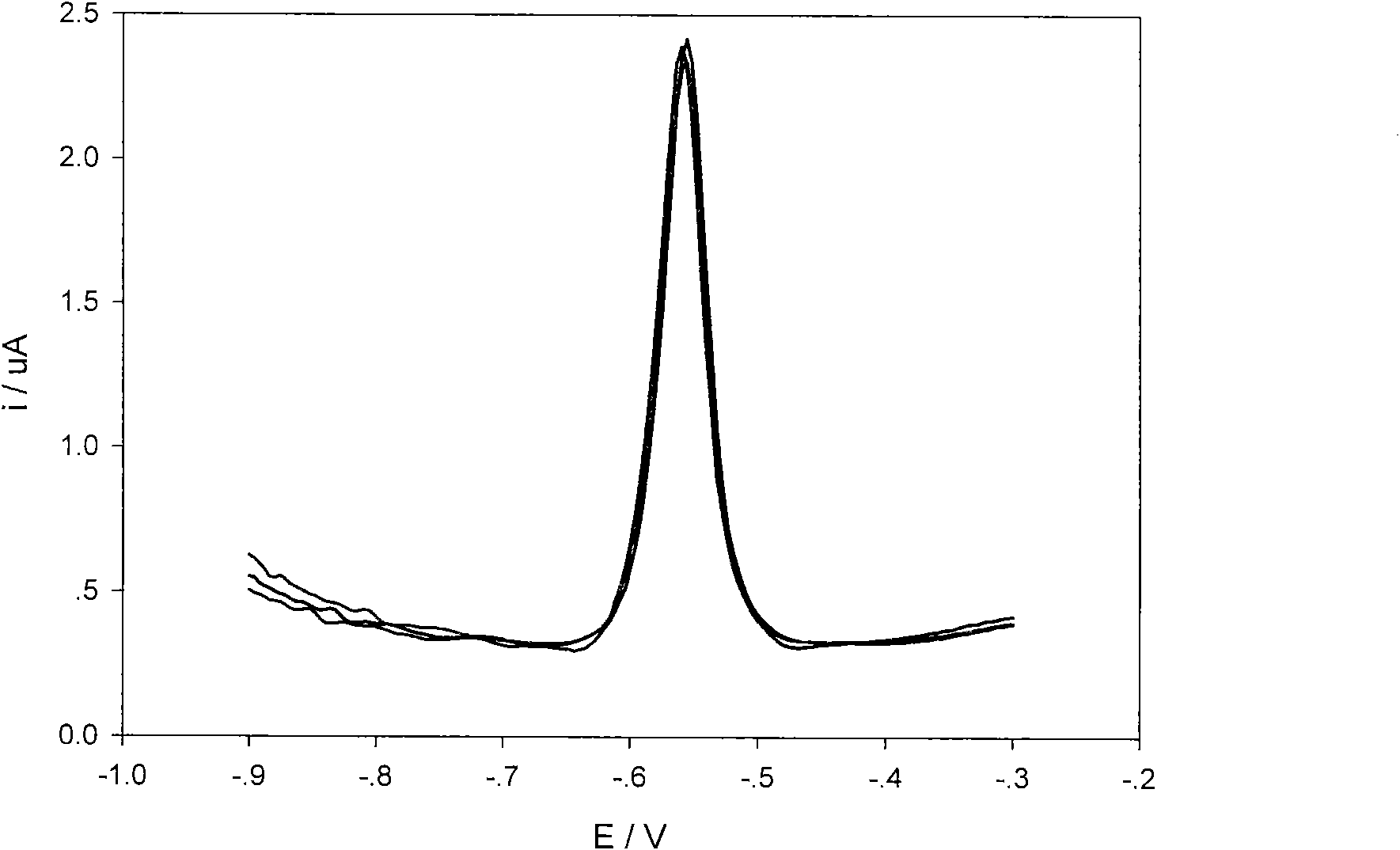

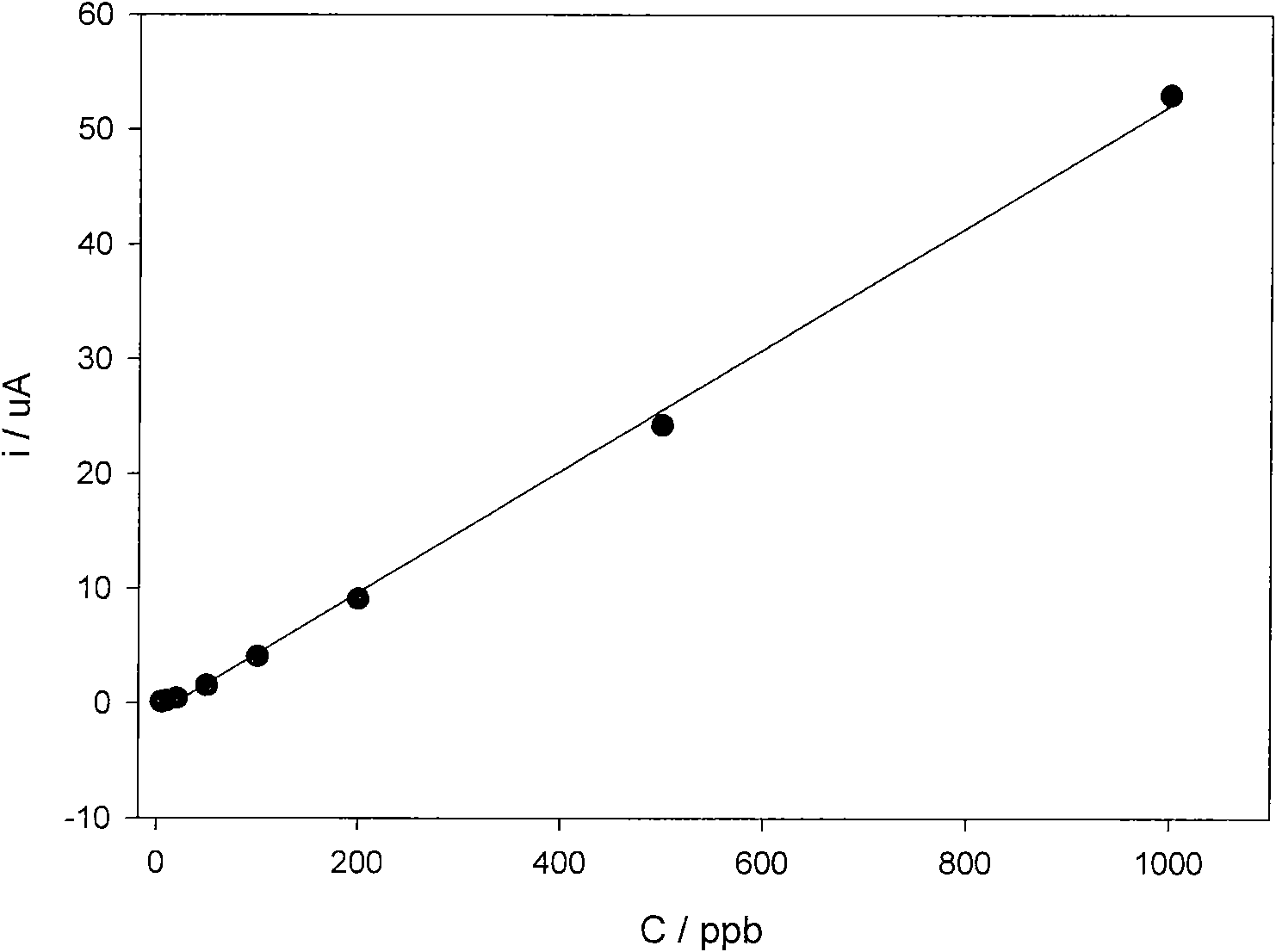

[0026] After polishing the platinum electrode, sweep cyclic voltammetry in 0.5M sulfuric acid solution until the electrode reaches a stable state, and then wash it with high-purity water. Put the platinum electrode into the electroplating solution, and pre-plate the bismuth film for 2 minutes. Add a standard lead ion solution with a concentration of 1 μmol / L to the detection solution, and co-deposit bismuth and lead at a constant potential of -0.9V for 3 minutes. Apply a positive scanning p...

Embodiment 3

[0028] The working electrode is a gold electrode, and the detection solution is a mixture of bismuth nitrate and hydrochloric acid, wherein the concentration of bismuth is 0.8mg / L, and the pH value of the solution is 1.5; the electroplating solution is a mixture of bismuth nitrate and phosphate buffer solution, wherein the concentration of bismuth is 1.5mg / L, the pH value of the solution is 3. The phosphate buffer solution is a mixed solution of phosphoric acid and disodium hydrogen phosphate.

[0029] After polishing the gold electrode, sweep cyclic voltammetry in 0.5M sulfuric acid solution until the electrode reaches a stable state, and then wash it with high-purity water. Put the gold electrode into the electroplating solution, and pre-plate the bismuth film for 1.5min. Add a standard lead ion solution to the detection solution, and co-deposit bismuth and lead at a constant potential of -1.0V for 3 minutes. Apply a positive scanning potential between -0.9 and -0.3V for o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com