High-weather-resistance acrylate resin composition and preparation method thereof

A resin composition and acrylate technology are used in the field of high weather-resistant acrylate resin compositions and their preparation, which can solve the problems of inferior low-temperature resistance performance as ABS resin, low-temperature cracking, poor weather resistance and the like, and achieve high low-temperature impact resistance. performance, improving heat distortion temperature, and suppressing the development of craze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 25Kg SAN resin 2, 46Kg methyl methacrylate, 7Kg fluorine-containing polymer, 7Kg silicone rubber-containing polymer, 4Kg compatibilizer, 3Kg antioxidant were added to a high-speed mixer and stirred for 20 minutes before discharging to obtain Mixture A.

[0073] Add mixture A from the main feeding port of the twin-screw extruder, mix 4Kg light absorber and 4Kg light stabilizer first, then add it from the side feeding port of the twin-screw extruder, extrude and granulate to obtain weather-resistant masterbatch , the barrel temperature of the extruder is 140° C., and the screw speed is 180 rpm.

[0074] Put 20Kg of ASA resin 1, 15Kg of ASA resin 2, 45Kg of SAN resin 1, 10Kg of heat-resistant modifier, 0.5Kg of lubricant, and 0.3Kg of antioxidant into a high-speed mixer and stir for 5 minutes before discharging to obtain mixture B.

[0075] Add mixture B from the main feeding port of the twin-screw extruder, add 10Kg of weather-resistant masterbatch from the side feeding ...

Embodiment 2-4

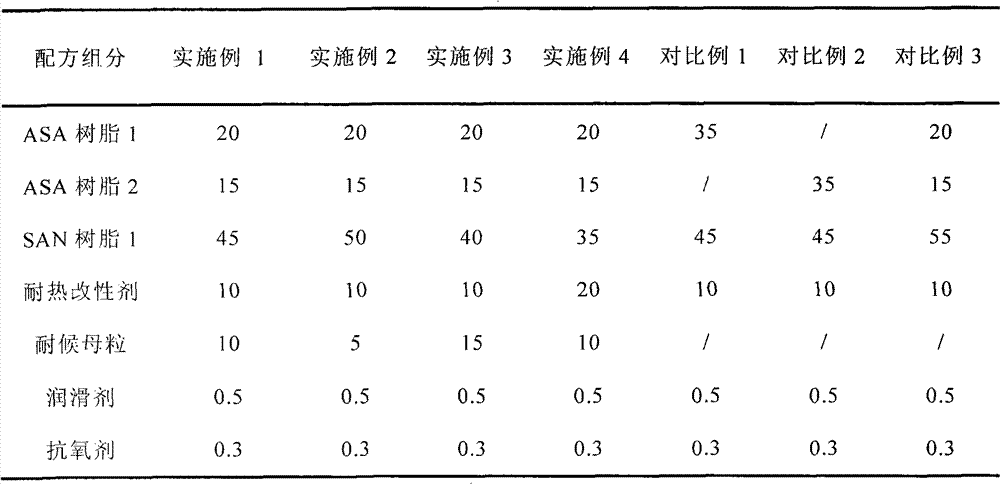

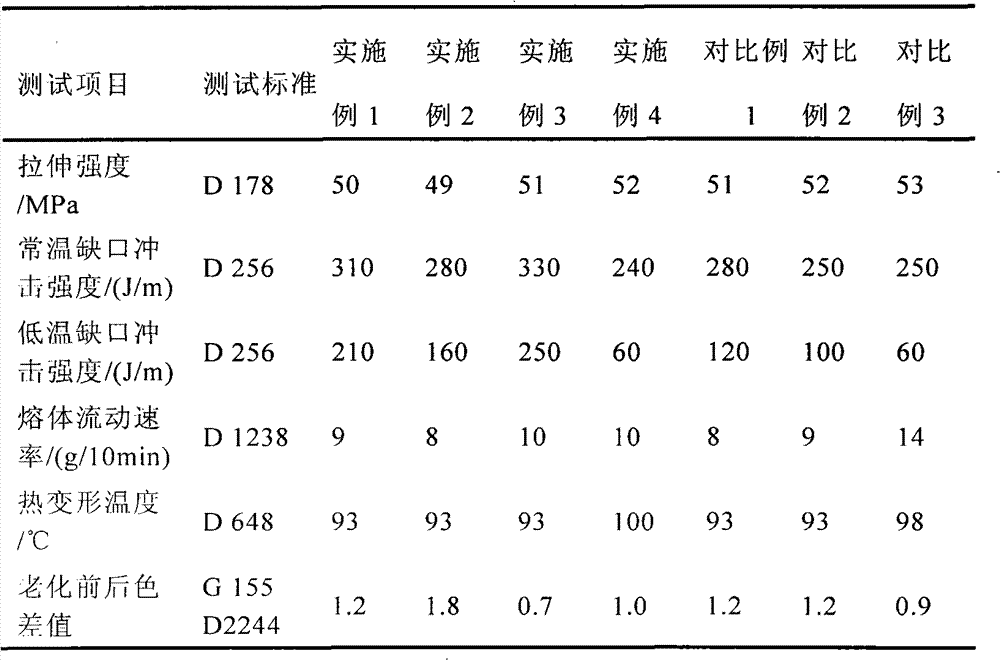

[0077] In order to better reflect the characteristics of the above-mentioned high weather-resistant acrylate resin composition, the present invention uses Examples 2-4 to compare the influence of different weather-resistant masterbatch dosages and different heat-resistant modifier dosages on product performance. The material formula is shown in Table 1, and the steps are the same as in Example 1.

Embodiment 5

[0094] A preparation method of a highly weather-resistant acrylate resin composition, the method comprising the following steps:

[0095] (1) Preparation of weather-resistant masterbatch:

[0096] a, with 10g SAN resin 2, this resin is the copolymer of acrylonitrile and styrene of ultra-high fluidity, and acrylonitrile content is 15wt%, and the weight average molecular weight is 30000, and 30g weight average molecular weight is the methyl methacrylate polymerization of 10000 Material, 5g polyvinylidene fluoride, 5g silicone rubber-containing polymer, the silicone rubber content is 60wt%, the glass transition temperature of the rubber is lower than minus 100°C, 3g compatibilizer ethylene-methacrylate-maleic anhydride and 3g antioxidant, the antioxidant is the mixture of hindered monophenol and phosphite compound, put into the high-speed mixer and stir for 5min and then discharge to obtain the mixture;

[0097] b. Add the mixture from the main feeding port of the twin-screw ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com