Silver paste for disk capacitor electrode

A capacitor electrode, silver paste technology, applied in fixed capacitor electrodes, parts of fixed capacitors, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of sintering performance, adhesion, welding resistance, etc. Achieve good electrical conductivity, continuous silver surface, and small sintering shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

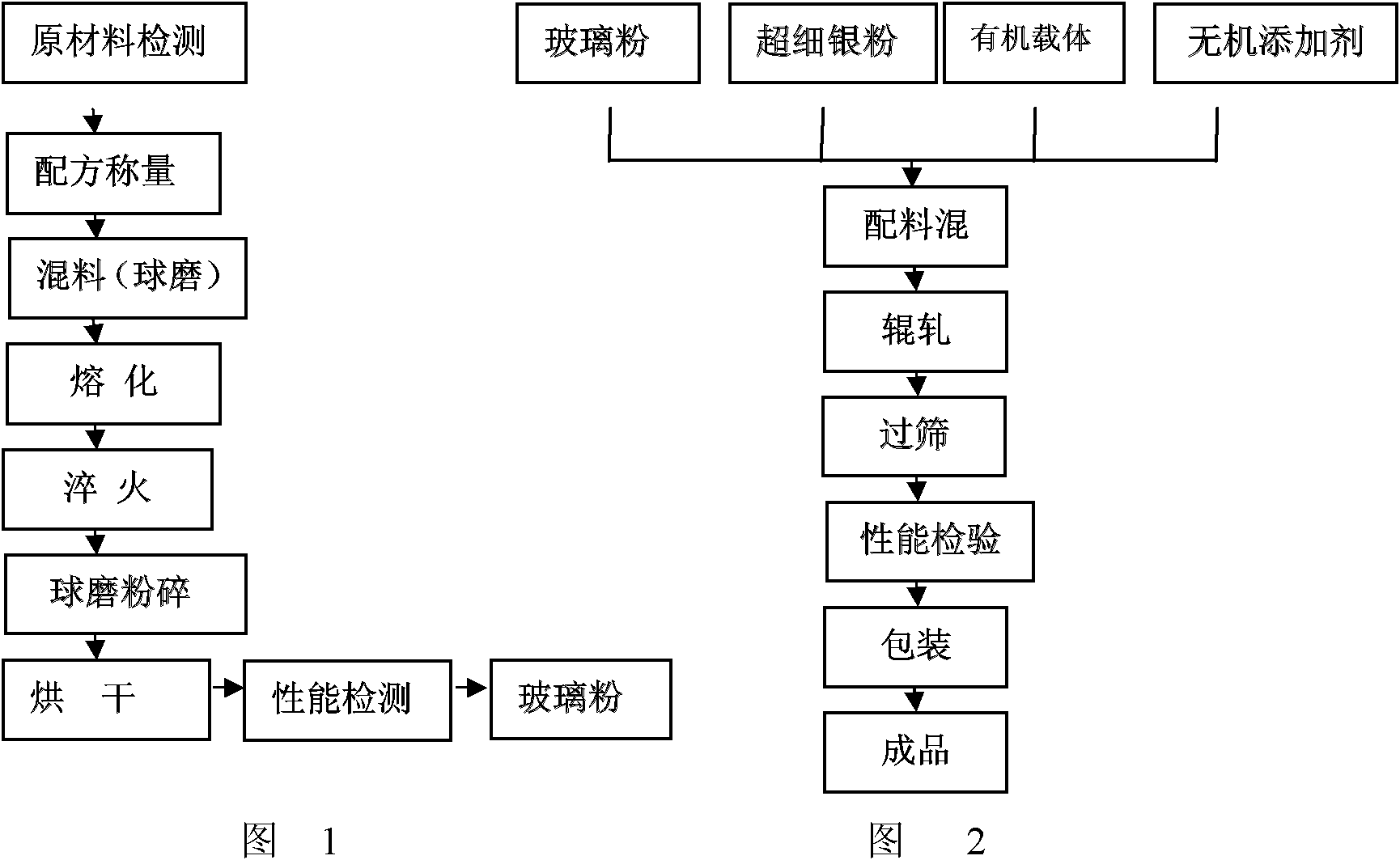

[0032] 1. Preparation of lead-free glass powder

[0033] By mass percentage B 2 o 3 20wt%, SiO 2 15wt%, Bi 2 o 3 60wt%, Al 2 o 3 3.5wt%, Y 2 o 3 1.5 wt%. Mix evenly with a pot mill, preheat at 450°C for 30 minutes, melt at 1200°C for 60 minutes, quench, ball mill until the particle size is less than 15 μm, filter and dry.

[0034] 2. Preparation of organic carrier

[0035] Ethyl cellulose 20Wt%, terpineol 30Wt%, diethylene glycol butyl ether 40Wt%, surfactant Wt 5%, leveling agent Wt 5%, after mixing the above components, heat and dissolve at 80-100°C, Obtain a transparent glue.

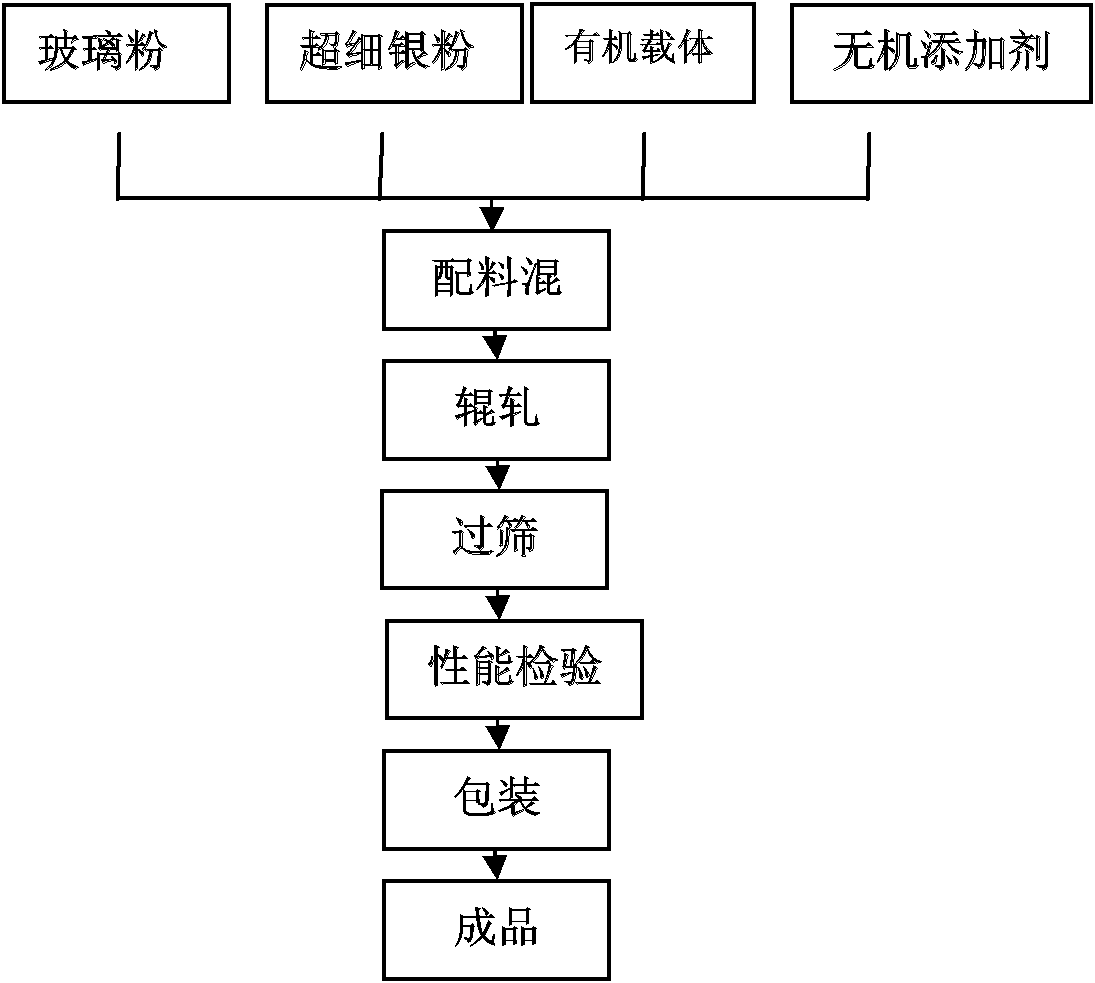

[0036] 3. Mix 60Wt% ultra-fine silver powder, 4Wt% lead-free glass powder, 1Wt% Y 2 o 3 , made into powder, after stirring evenly, adding 35wt% organic carrier, after high-speed dispersion, rolled by three-roll mill until the fineness is less than 10 μm, adding diethylene glycol monobutyl ether to adjust the viscosity.

[0037] How to use the silver paste:

[0038] ① Screen printing on...

Embodiment 2

[0043] 1. Preparation of lead-free glass powder

[0044] By mass percentage B 2 o 3 18wt%, SiO 2 17Wt%, Bi 2 o 3 60wt%, Al 2 o 3 1.5wt%, TiO 2 and ZrO 2 3.5 wt%. Mix evenly with a pot mill, preheat at 450°C for 30 minutes, melt at 1200°C for 60 minutes, quench, ball mill until the particle size is less than 15 μm, filter and dry.

[0045] 2. Preparation of organic carrier

[0046] Ethyl cellulose 25wt%, terpineol 30wt%, diethylene glycol butyl ether 33wt%, surfactant 6wt%, leveling agent 6wt%, after mixing the above components, heat and dissolve at 80-100 ℃ to obtain Transparent glue.

[0047] 3. Mix 58Wt% ultra-fine silver powder, 3.5Wt% lead-free glass powder, 2.3Wt% TiO 2 and ZrO 2 , made into powder, after stirring evenly, adding 36.2Wt% organic carrier, after high-speed dispersion, rolling to fineness less than 10 μm by three-roll rolling mill, adding terpineol to adjust viscosity.

[0048] How to use the silver paste: Please refer to Example 1

Embodiment 3

[0050] 1. Preparation of lead-free glass powder

[0051] By mass percentage B 2 o 3 22wt%, SiO 2 20Wt%, Bi 2 o 3 52wt%, Al 2 o 3 0.5wt%, FeO 5.5wt%. Mix evenly with a pot mill, preheat at 450°C for 30 minutes, melt at 1200°C for 60 minutes, quench, ball mill until the particle size is less than 15 μm, filter and dry.

[0052] 2. Preparation of organic carrier

[0053] Ethyl cellulose 28wt%, terpineol 30wt%, diethylene glycol butyl ether acetate 33wt%, surfactant 3wt%, leveling agent 6wt%, after mixing the above components, heat and dissolve at 80-100 ℃ , to obtain a transparent glue.

[0054] 3. Mix 55Wt% superfine silver powder, 4% lead-free glass powder, 1Wt% La 2 o 3 , made into powder, stirred evenly, added 35wt% organic carrier, dispersed at high speed, rolled by three-roll mill to fineness less than 10 μm, added diethylene glycol butyl ether acetate to adjust viscosity.

[0055] How to use the silver paste: Please refer to Example 1

[0056] Use the above si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Glass softening temperature | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com