Method for processing inferior crude oil through combined processes

A low-quality crude oil, combined process technology, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil and other directions, can solve the problems of low liquid yield and complex process flow, achieve quality improvement, oil slurry yield reduction, operation The effect of cycle improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

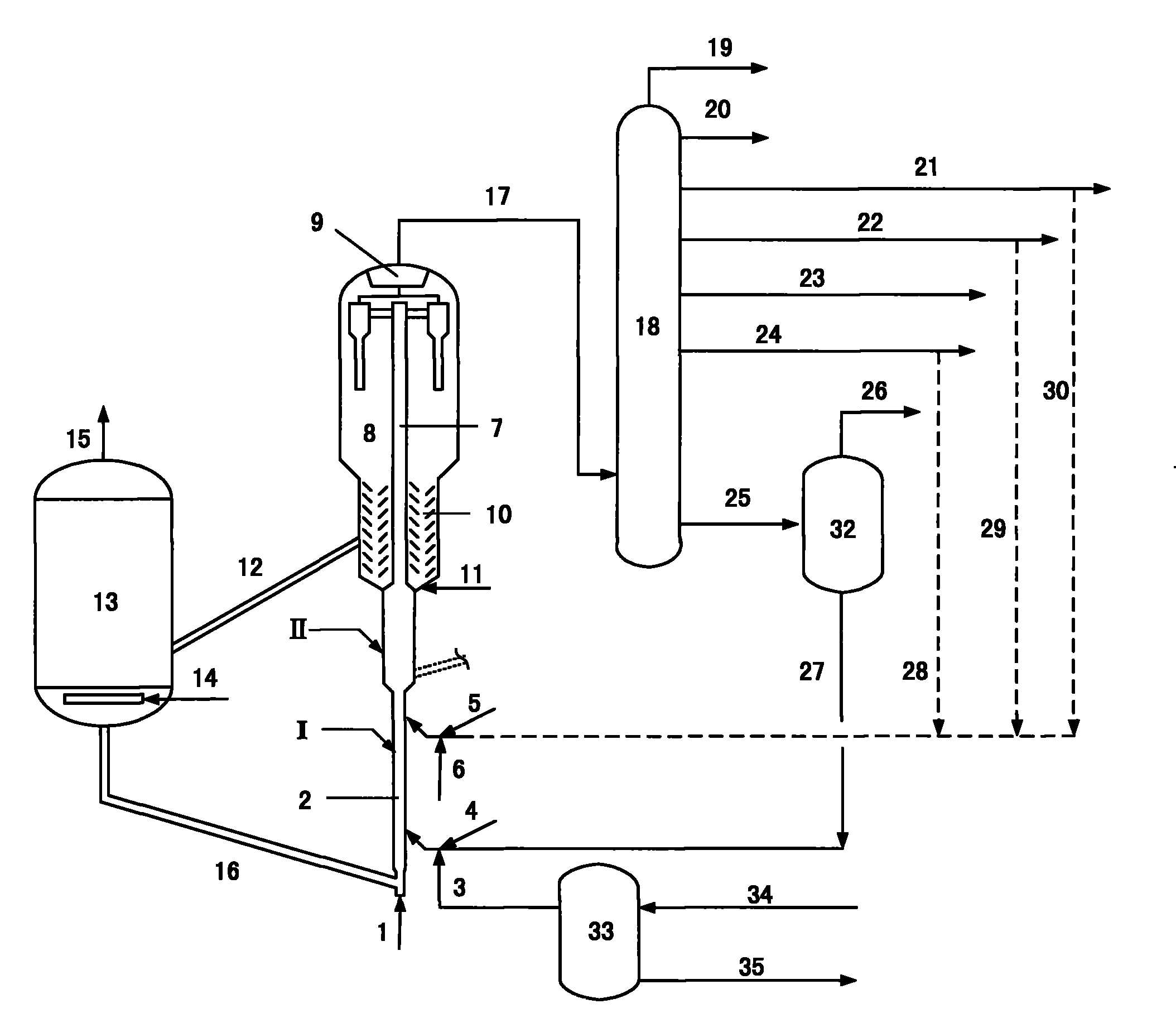

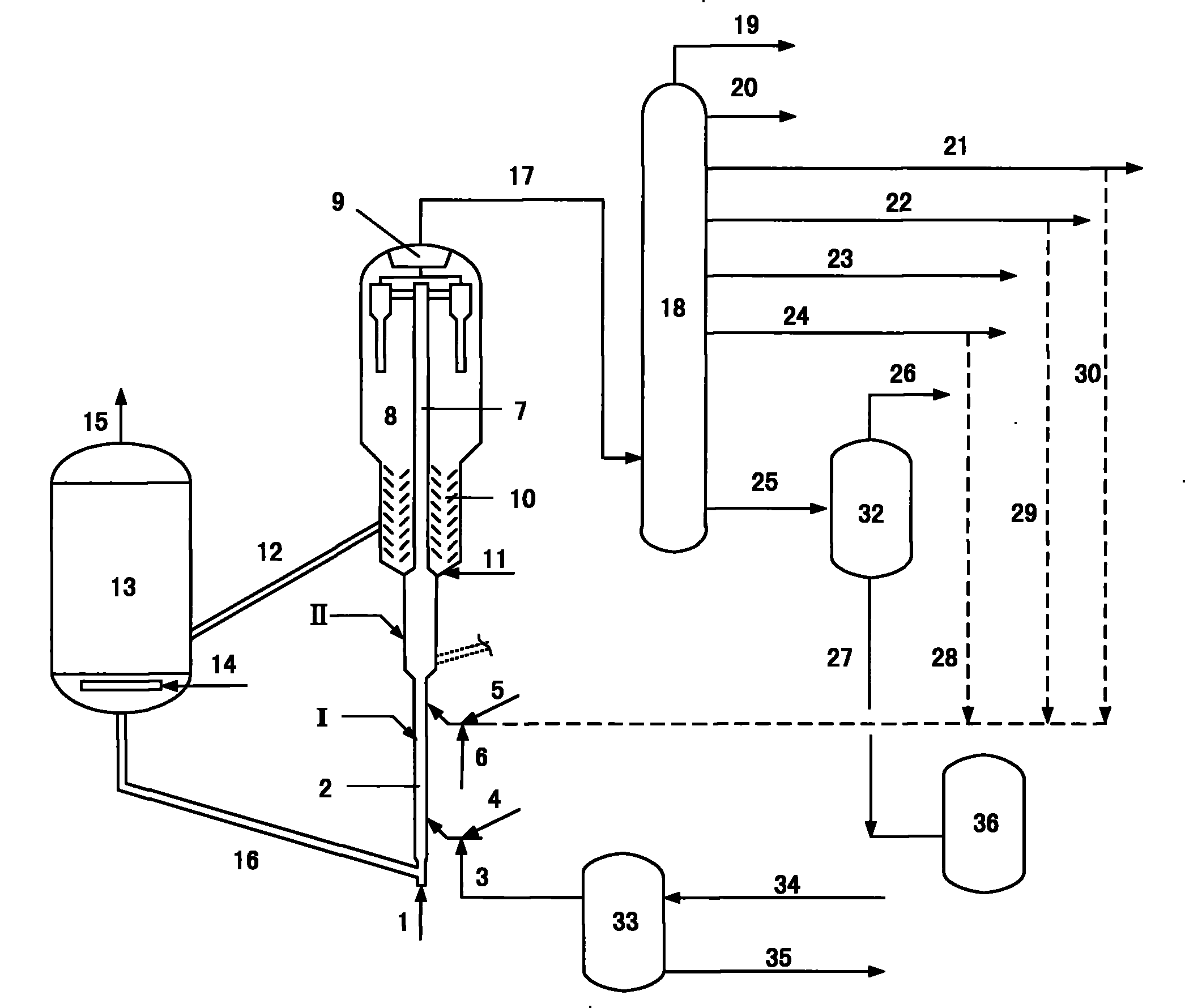

Method used

Image

Examples

Embodiment

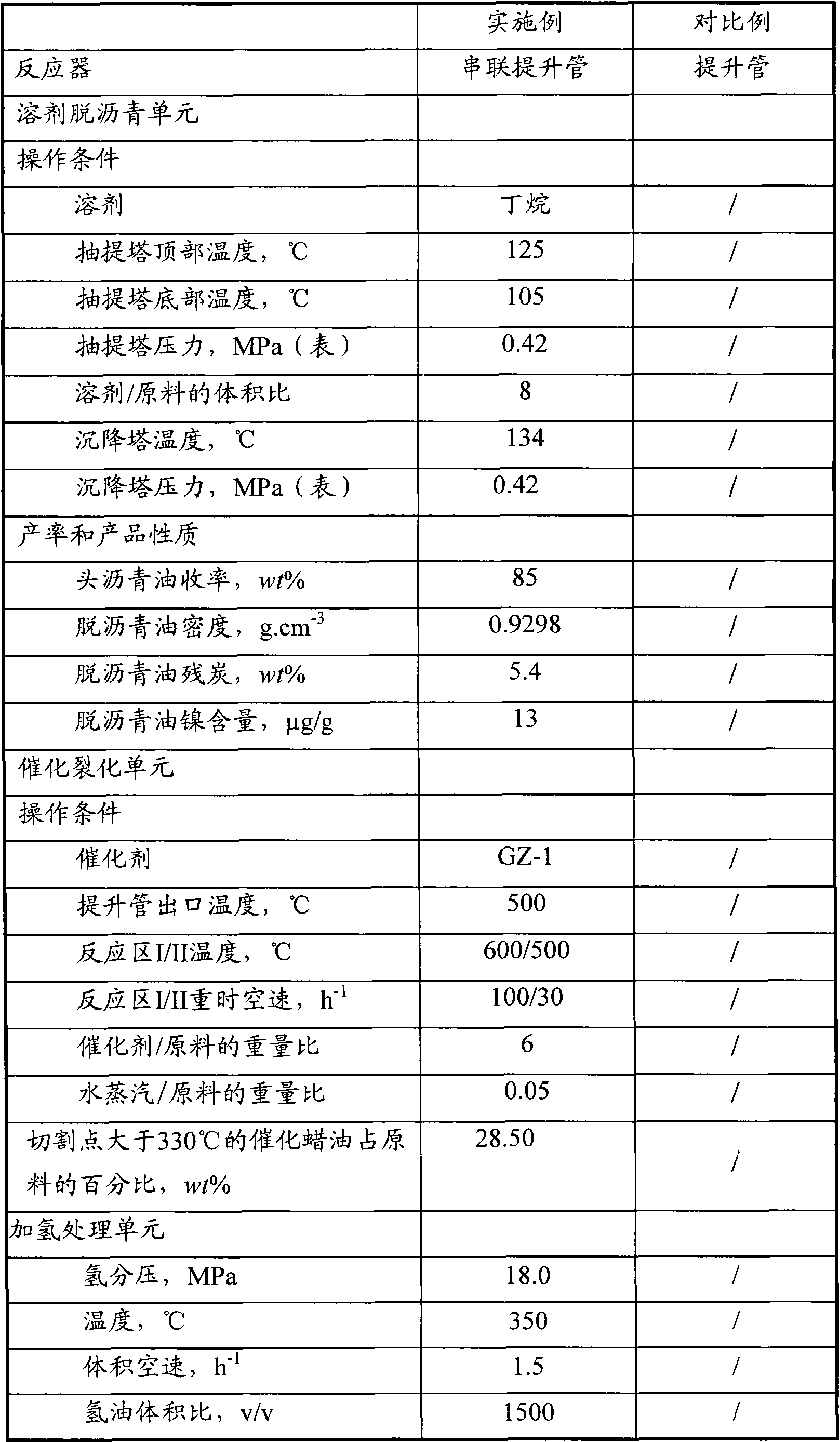

[0062] The examples illustrate the process and effect of the combined process provided by the present invention for treating inferior heavy oil raw materials.

[0063] The raw material oil A of vacuum residual oil is used as the raw material. After preheating, the raw material A enters the middle or upper part of the extraction tower of the solvent deasphalting medium-sized device, and enters the lower part of the extraction tower with butane as the solvent. The raw material and solvent are extracted Countercurrent contact extraction is carried out in the tower, deasphalted oil with a large amount of solvent flows out from the top of the extraction tower, and deoiled asphalt with a small amount of solvent is discharged from the bottom of the extraction tower. Solvents are recovered and reused from deoiled bitumen and deasphalted oil to yield deasphalted oils, gums and bitumens. The operating conditions of the extraction tower are shown in Table 3.

[0064] The obtained deasph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com