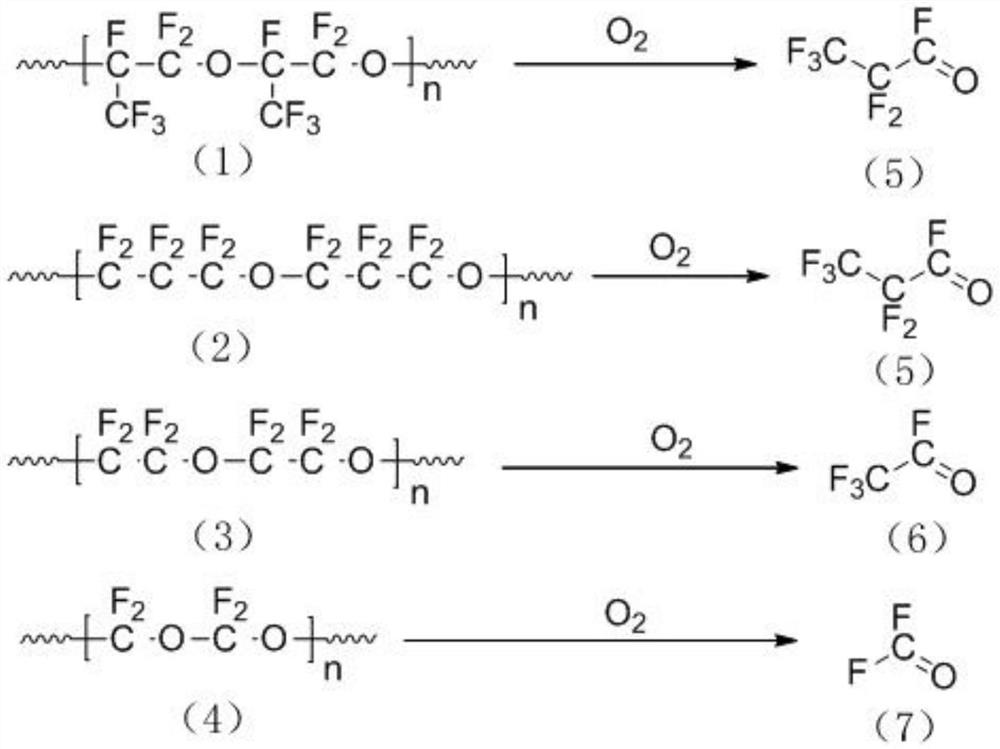

Method for synthesizing small-molecular-weight acyl fluoride through oxidative cracking of low-molecular-weight perfluoropolyether waste at high temperature

A technology of perfluoropolyether and low molecular weight, which is applied in the fields of organic chemistry and acyl halide preparation. It can solve the problems of low reaction temperature, poor practical usability, and high price of rare earth oxides, so as to achieve efficient utilization and multiple utilization and reduce environmental damage. , The effect of small environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

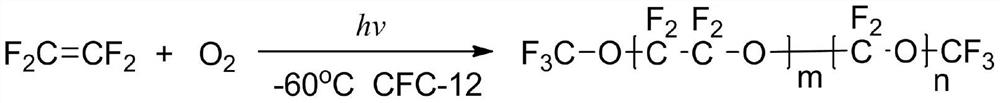

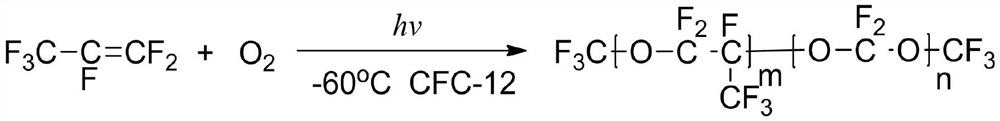

Method used

Image

Examples

Embodiment 1

[0061] Pump 1.3kg K-type perfluoropolyether (average molecular weight 1100) into the vaporization chamber through a peristaltic pump for preheating and vaporization. The flow rate is controlled by a flow controller at 4g / min. The temperature in the vaporization chamber is 200°C. After vaporization, the K-type The perfluoropolyether raw material and oxygen (oxygen flow rate: 30mL / min) are passed into the reaction furnace for high-temperature oxidative cracking reaction. The temperature of the reaction furnace is controlled at 500°C. The reaction residence time is 44s. After the reaction, the pyrolysis gas flow is pre-cooled to below 80°C and then passed into the absorption liquid (the absorption liquid is a mixture of methanol and triethylamine) to absorb and form a sample detection liquid. The excess gas insoluble in the absorption liquid ( including excess oxygen) is collected by air pockets. After the reaction, the weight of the absorbent liquid increased by 1.19 kg, and the...

Embodiment 2

[0069] Pump 1.3kg Z-type perfluoropolyether (average molecular weight 1000) into the vaporization chamber through a peristaltic pump for preheating and vaporization. The flow rate is controlled by a flow controller at 4g / min. The temperature in the vaporization chamber is 200°C. After vaporization, the Z-type The perfluoropolyether raw material and oxygen (oxygen flow rate: 30mL / min) are passed into the reaction furnace for high-temperature oxidative cracking reaction. The temperature of the reaction furnace is controlled at 500°C. The reaction residence time is 44s. After the reaction, the pyrolysis gas flow is pre-cooled to below 80°C and then passed into the absorption liquid (the absorption liquid is a mixture of methanol and triethylamine) for absorption to form a sample detection liquid. The excess gas is collected with an air bag. After the reaction, the weight of the absorption liquid increased by 1.205kg, and the weight of the air bag increased by 0.08kg. The gaseous...

Embodiment 3

[0073] Pump 1.3kg D-type perfluoropolyether (average molecular weight 1100) into the vaporization chamber through a peristaltic pump for preheating and vaporization. The flow rate is controlled by a flow controller at 4g / min. The temperature in the vaporization chamber is 200°C. After vaporization, the D-type The perfluoropolyether raw material and oxygen (oxygen flow rate: 30mL / min) are passed into the reaction furnace together for high-temperature oxidative cracking reaction. The temperature of the reaction furnace is controlled at 500°C. The reaction residence time is 44s. After the reaction, the pyrolysis gas flow is pre-cooled to below 80°C and then passed into the absorption liquid (the absorption liquid is a mixture of methanol and triethylamine) for absorption to form a sample detection liquid. The excess gas is collected with an air bag. After the reaction, the weight of the absorbent liquid increased by 1.201 kg, and the weight of the air bag increased by 0.095 kg. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com