Magnesium electrode for magnesium battery and preparation method thereof

A technology of magnesium electrodes and magnesium batteries, applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve the problems of weak matrix bonding, the appearance of passivation films, unsuitable high current discharge, etc., to achieve easy high current discharge, Good quality and good discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Ultrasonic cleaning of the base material nickel foam in acetone solution, just clean it;

[0034] 2. Electroplating the copper layer on the bottom layer of the base material, the electroplating conditions are about 55°C, and the current density is 15mA / cm 2 , plating time is 3min.

[0035] Among them: the formula of copper electroplating solution: potassium pyrophosphate 350g / L, ammonium nitrate 20g / L, copper sulfate 90g / L, pH value is controlled at 8.2-8.8.

[0036] 3. Electrodeposition of magnesium on the surface of the base material, constant current electrodeposition, the current density is 1.0mA·cm -2 , The electrodeposition time is 1h.

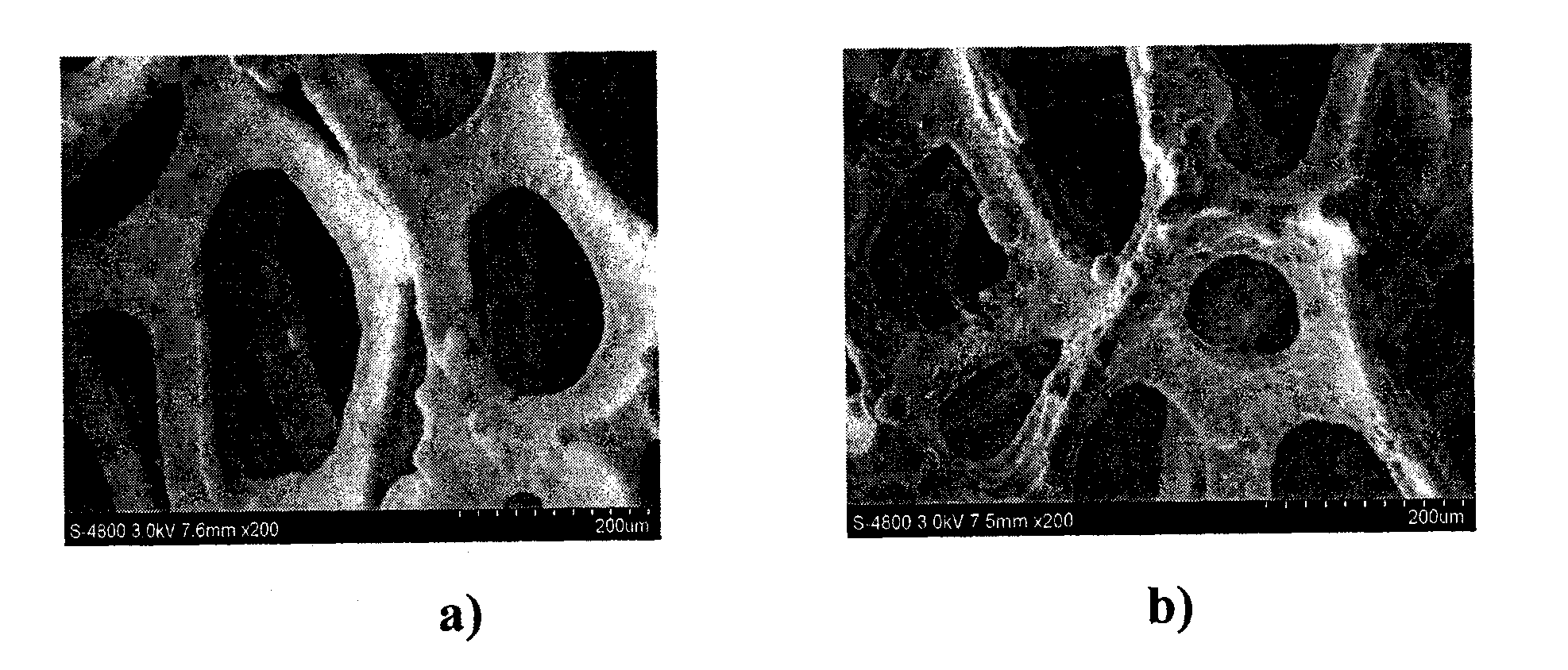

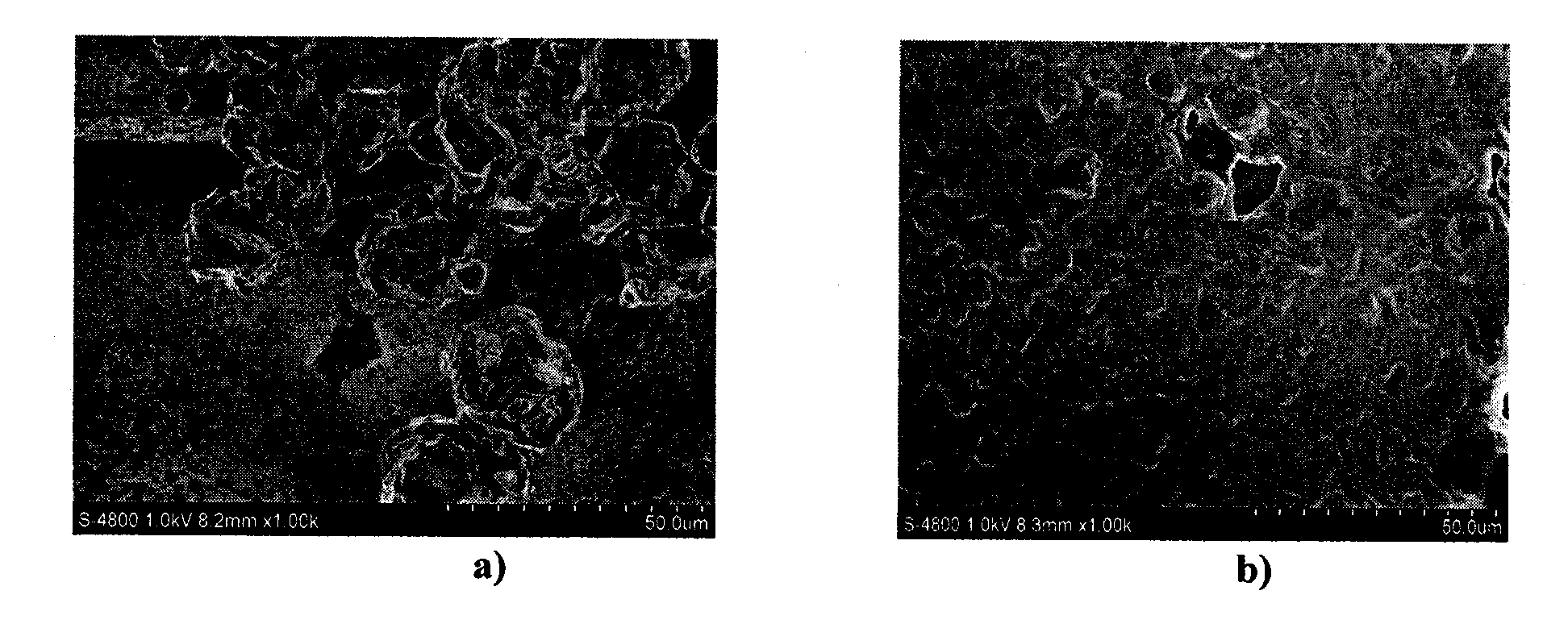

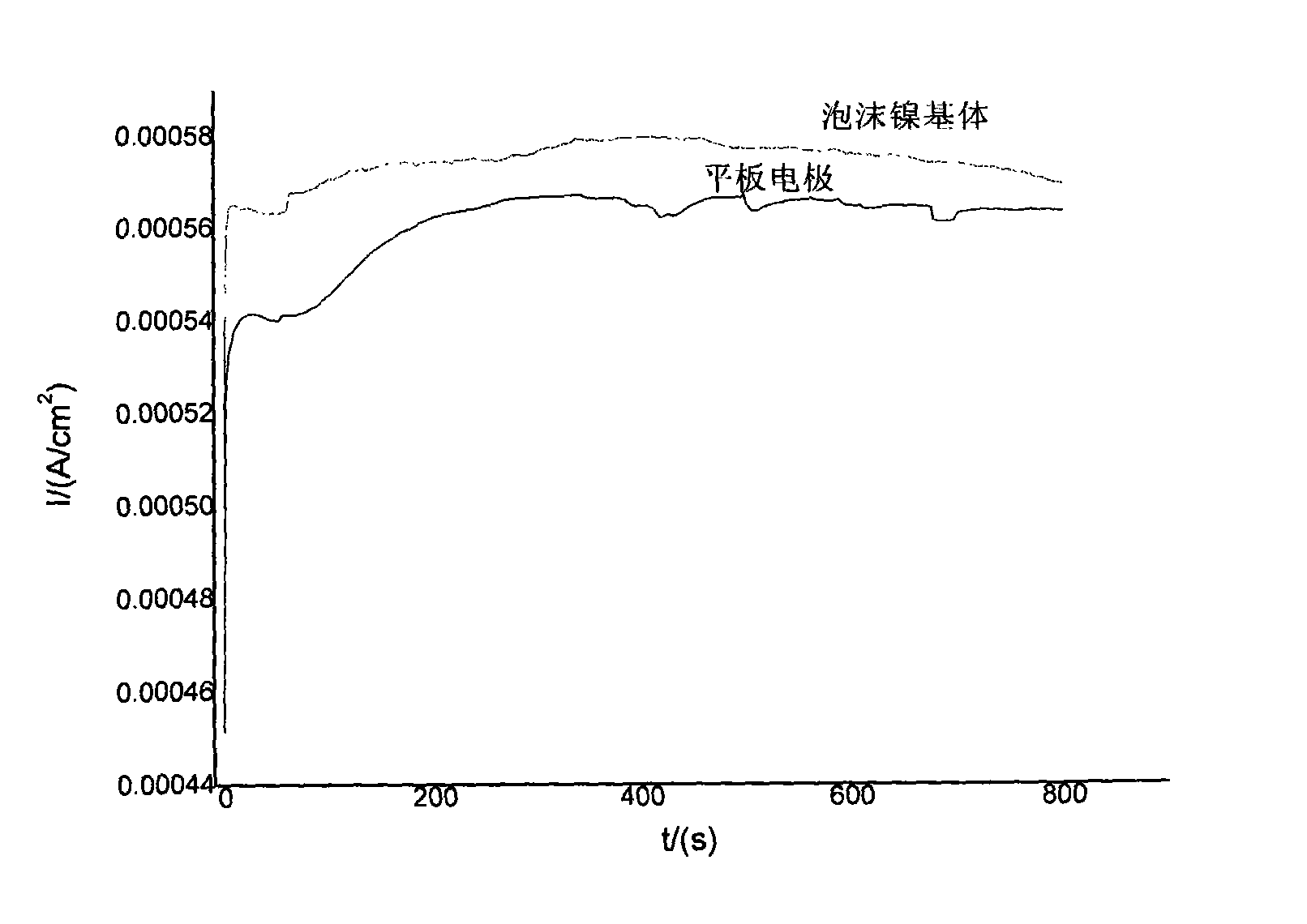

[0037] The electrode area of the electrode substrate is 0.26cm 2 , both the counter electrode and the reference electrode use magnesium strips (purity 99.99%), and the electrolyte is 1.0M EtMgBr / THF solution, thus obtaining a magnesium electrode with a double-layer structure, and its surface morphology is as follows figur...

Embodiment 2

[0042] The base material is copper foil, and the electrodeposition of magnesium is directly carried out.

[0043] All the other are identical with embodiment 1.

[0044] Repeat the above test, the results are recorded in Table 1, the surface SEM image is as follows figure 2 b) as shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com