Sugarcane insecticide containing neonicotinoid insecticide

A neonicotinoid and insecticide technology, applied in the directions of insecticides, biocides, animal repellents, etc., can solve the problem that the sugarcane crops cannot be well applied, the control effect of underground pests is not ideal, and the pests develop drug resistance. and other problems, to achieve the effect of overcoming pest resistance, protecting biodiversity and long lasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Granule preparation (by weight percentage):

[0051] Thiamethoxam 0.8%, oximephos 1.2%, diesel oil 1%, polyvinyl alcohol 0.4%, and the rest is quartz sand (fineness: 0.85-2.00mm). The components are stirred and mixed evenly to make granules.

[0052] The usage method of the mixture is as follows: it is applied to the sugarcane planting ditch during the next planting stage of the sugarcane, and the dosage is 60-80 g / mu of active ingredients.

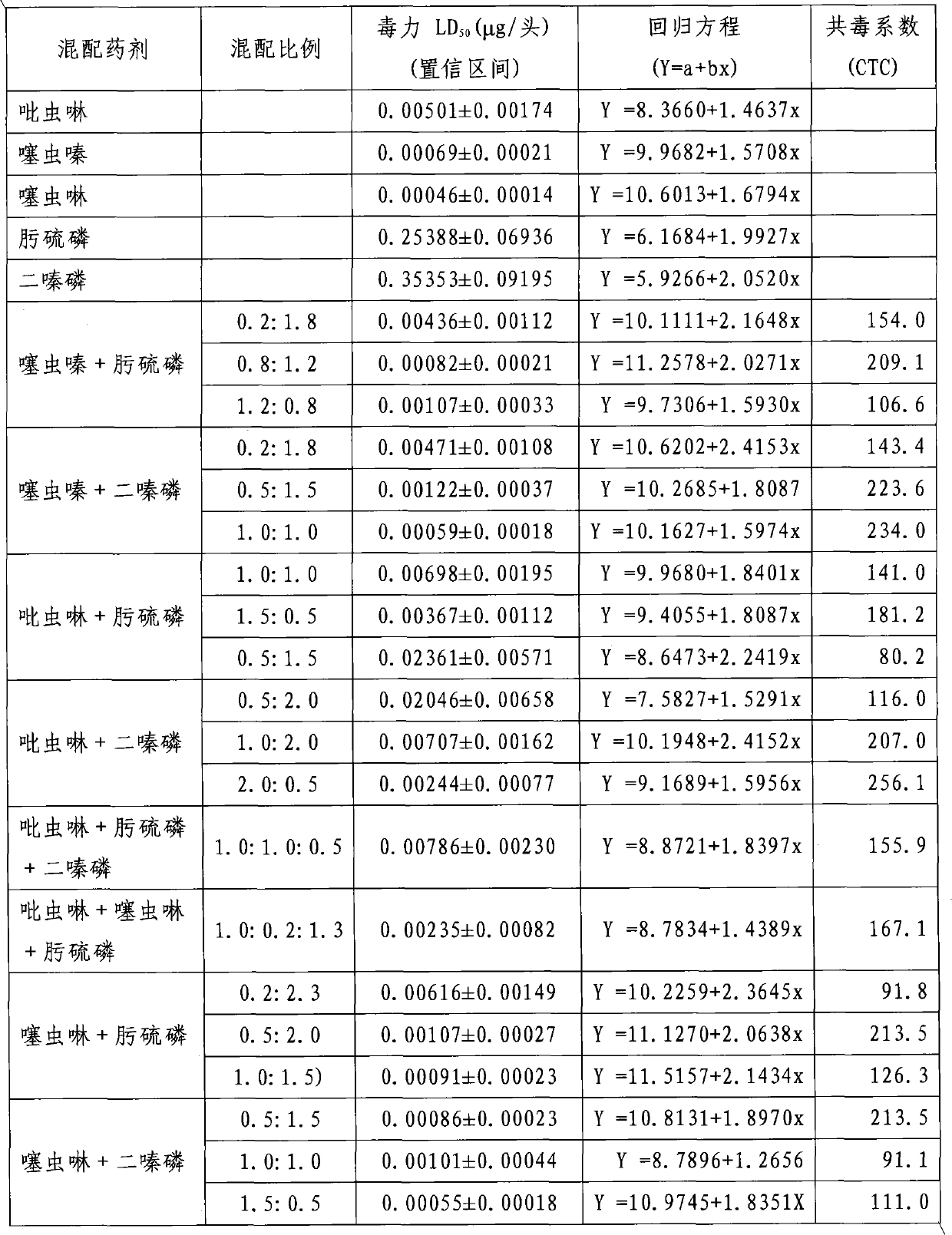

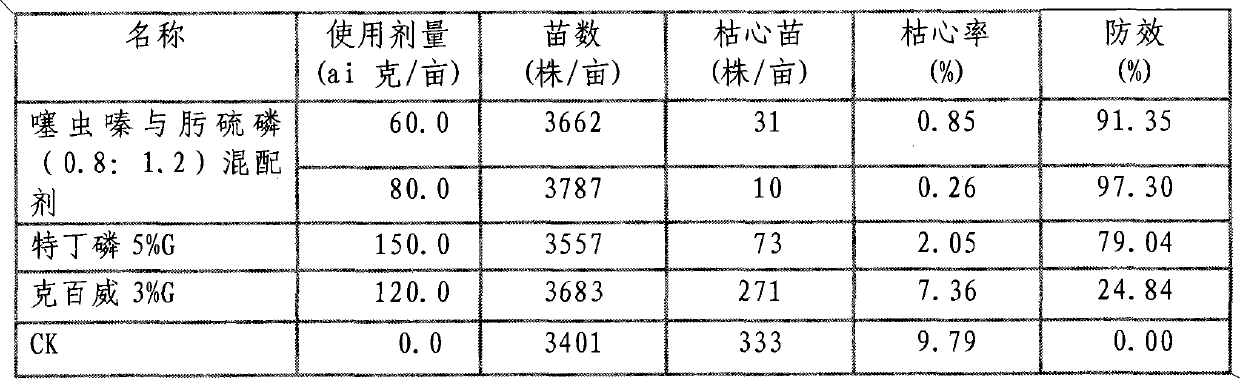

[0053] Table 2 is the control effect of the mixture on sugarcane borer. It can be seen from Table 2 that the mixture of thiamethoxam and oximathion at a ratio of 0.8:1.2 has excellent control effect on sugarcane borers, and the control effect of 60-80g of active ingredients per mu reaches 91.35-97.30%, which is obviously better than that of the control agent. Control efficacy of fenthion and carbofuran.

Embodiment 2

[0055] Granule preparation (by weight percentage):

[0056] Thiamethoxam technical 0.5%, diazinon technical 1.5%, diesel oil 1%, polyvinyl alcohol 0.4%, the rest is quartz sand (fineness 0.85-2.00mm), each component is stirred and mixed evenly to make Granules.

[0057] The use method of the mixed preparation is as follows: the sugarcane is applied to the sugarcane planting ditch during the next planting period, and the dosage is 40-80 g / mu of active ingredients.

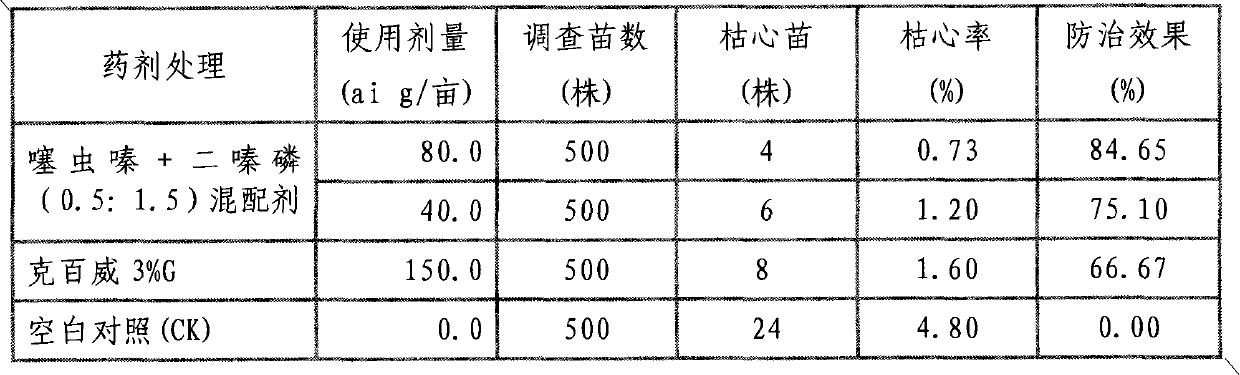

[0058] Table 3 is the test effect of this mixture on sugarcane black cane turtle. The data shows that the control effect of the compound agent on sugarcane black cane turtle with 40g and 80g of active ingredients per mu reaches 75.10% and 84.65% respectively, which is better than the effect of the contrast agent carbofuran.

[0059] Table 4 is the control test effect of the mixture on sugarcane borer. The results show that the control effect on sugarcane borer is 69.06-81.77% when 40-80 g of active ingredients ar...

Embodiment 3

[0061] Granule preparation (by weight percentage):

[0062] 0.5% of imidacloprid technical material, 8.5% of oximephos technical material, 0.3% of lauryl azone, 1% of paraffin wax, and the rest is quartz sand (fineness: 0.85-2.00mm). Each component is stirred and mixed evenly to prepare Granules.

[0063] The usage method of the mixed preparation is as follows: the sugarcane is applied to the sugarcane planting ditch during the next planting period, and the dosage is 120-150 g / mu of active ingredients.

[0064] Table 5 is the experimental effect of the compounding agent on sugarcane brown beetle larvae (grubs). The data shows that the control effect of the mixture on grubs with 120g and 150g of active ingredients per mu reaches 70.59% and 77.38%, respectively, which is better than that of the control agents terbufos and carbofuran. However, the effect of 90g / mu of active ingredient is only 66.81%, and its control effect is slightly better than that of the contrast agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com