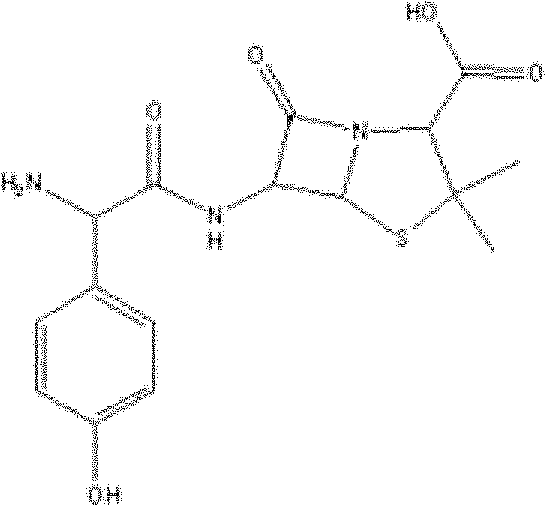

Amoxicillin particle and preparation process thereof

A technology of amoxicillin and granules, which is applied in the field of amoxicillin granules and its preparation technology, can solve the problems of easily decomposed allergic polymer impurities, poor stability, etc., to avoid penicillin allergic reactions, improve stability, curative effect and The effect of security assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

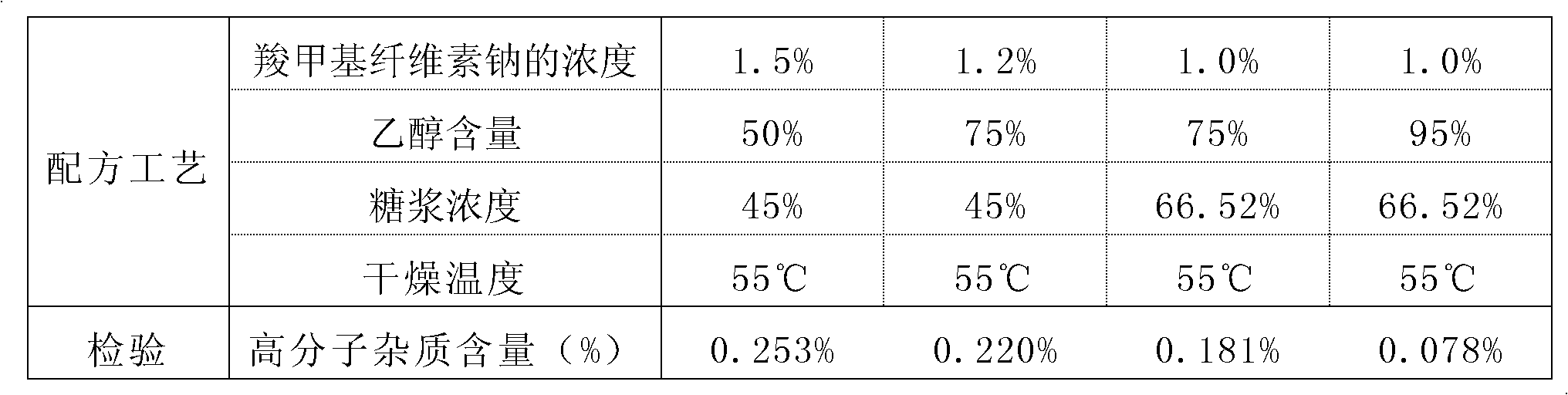

Embodiment 1

[0042]

[0043] Preparation Process:

[0044] (1) Weigh Amoxicillin.

[0045] (2) Mix and pulverize auxiliary materials such as citric acid, sodium citrate, tartrazine, sodium carboxymethylcellulose and sucrose, and pass through an 80-mesh sieve.

[0046](3) Prepare an adhesive solution, which is prepared in proportion to 1.0wt% sodium carboxymethylcellulose in 95% ethanol solution and 66.52wt% syrup.

[0047] (4) Mix amoxicillin and auxiliary materials, add binder solution, place in the hopper of a high-efficiency wet granulator, close the material box, turn on the paddle and the cutter to mix at low speed for 5 minutes, stop stirring, and add 95% Proper amount of ethanol, turn on the paddle stirring and cutter, stir at a slow speed for 120 seconds, stop the stirring, add 1% sodium carboxymethyl cellulose slurry, and when the high-speed stirring reaches 60 seconds, add syrup from the observation port, and stir at a high speed From 180 seconds to 240 seconds, use the clea...

Embodiment 2

[0053]

[0054]

[0055] Preparation Process:

[0056] (1) Weigh Amoxicillin.

[0057] (2) Mix and pulverize auxiliary materials such as citric acid, sodium citrate, tartrazine, sodium carboxymethylcellulose and sucrose, and pass through an 80-mesh sieve.

[0058] (3) Prepare an adhesive solution, which is prepared in proportion to 1.0% carboxymethylcellulose sodium in 95% ethanol solution and 70.0% syrup.

[0059] (4) Mix amoxicillin and auxiliary materials, add binder solution, place in the hopper of a high-efficiency wet granulator, close the material box, turn on the paddle and the cutter to mix at low speed for 5 minutes, stop stirring, and add 95% Appropriate amount of ethanol, turn on the paddle stirring and cutter, stir at a slow speed for 120 seconds, stop stirring, add 1.0% sodium carboxymethyl cellulose slurry, and when the high-speed stirring reaches 60 seconds, add syrup from the observation port, and stir at a high speed From 180 seconds to 240 seconds, u...

Embodiment 3

[0065]

[0066] Preparation Process:

[0067] (1) Weigh Amoxicillin.

[0068] (2) Mix and pulverize auxiliary materials such as citric acid, sodium citrate, tartrazine, sodium carboxymethylcellulose and sucrose, and pass through an 80-mesh sieve.

[0069] (3) Prepare an adhesive solution, which is prepared in proportion to 1.0% carboxymethylcellulose sodium in 95% ethanol solution and 65% syrup.

[0070] (4) Mix amoxicillin and auxiliary materials, add binder solution, place in the hopper of a high-efficiency wet granulator, close the material box, turn on the paddle and the cutter to mix at low speed for 5 minutes, stop stirring, and add 95% Appropriate amount of ethanol, turn on the paddle stirring and cutter, stir at a slow speed for 120 seconds, stop stirring, add 1.0% sodium carboxymethyl cellulose slurry, and when the high-speed stirring reaches 60 seconds, add syrup from the observation port, and stir at a high speed From 180 seconds to 240 seconds, use the cleaned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com