Synthetic method of 3-chloro-2-hydroxypropyl-trimethyl ammonium chloride and aqueous solution product obtained during preparation process thereof

A technology of trimethylammonium chloride and a synthesis method, applied in the field of aqueous solution products, can solve the problems such as the catalyst cannot be recycled, the pH value is difficult to control, the efficiency is low, etc., and the yield is high, the pH value is easy to control, and the energy consumption is low. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

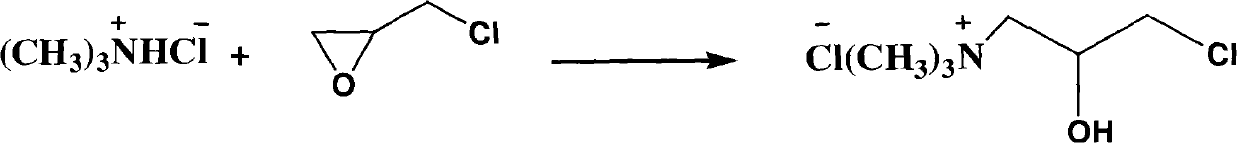

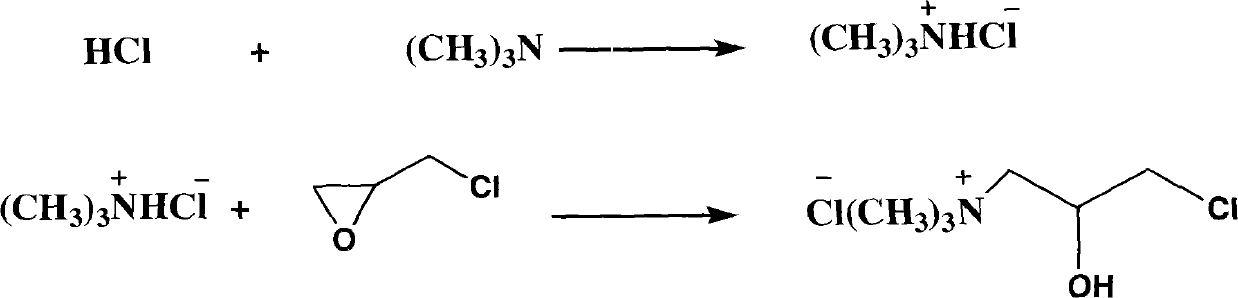

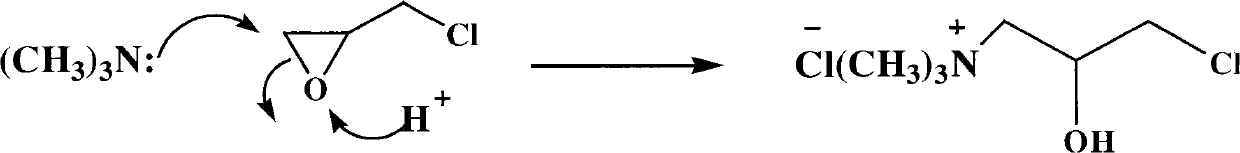

Method used

Image

Examples

Embodiment 1

[0035] 1, Synthesis of 3-chloro-2-hydroxypropyl-trimethylammonium chloride aqueous solution:

[0036] Add 70g of trimethylamine hydrochloride and 64ml of water into the reaction flask, start stirring until the trimethylamine hydrochloride is completely dissolved, then add alkaline Al 2 o 3 Catalyst 10g, keep the pH value of the system at 7.8, after cooling down to 5°C, add 66g of epichlorohydrin (ECH) dropwise, and keep it warm until the pH value of the system reaches the peak value of 9.7. At this time, the system is a homogeneous system. It lasted 3 hours; then, it was transferred to room temperature and reacted for 2 hours at 18°C. When the pH value of the reaction system dropped to 8.8, the reaction was completed; the catalyst was filtered to remove the crude product, and 2 times the volume of deionized water was continuously added to the crude product. Control the vacuum degree at 740mmHg, and carry out continuous vacuum azeotropic distillation at 48°C to obtain solid co...

Embodiment 2

[0040] 1, Synthesis of 3-chloro-2-hydroxypropyl-trimethylammonium chloride aqueous solution:

[0041] Add 70g of trimethylamine hydrochloride and 60mL of water in sequence in the reaction bottle, start stirring until the trimethylamine hydrochloride is completely dissolved, then add KF / basic Al 2 o 3 Composite catalyst 7g, keep the pH value of the system at 8. Cool down to 2°C and add 67g of ECH dropwise. After dropping, keep warm until the pH value of the system reaches the peak value of 10. At this time, the system is a homogeneous system, which lasts for 5 hours. Then, turn to room temperature 25 ℃ and react for 2 hours, when the pH value of the reaction system drops to 7.8, the reaction ends; the catalyst is removed by filtration to obtain the crude product, and 4 times the volume of deionized water is continuously added to the crude product, and the vacuum degree is controlled at 760mmHg, continuous vacuum azeotropic distillation at 58°C to obtain solid content: 70.1% (...

Embodiment 3

[0045] 1, Synthesis of 3-chloro-2-hydroxypropyl-trimethylammonium chloride aqueous solution:

[0046] Add 70g of trimethylamine hydrochloride and 70mL of water in sequence in the reaction bottle, start stirring until the trimethylamine hydrochloride is completely dissolved, then add K 2 CO 3 / Neutral Al 2 o 3 Composite catalyst 14g, keep the pH value of the system at 8. Cool down to 0°C and add 68g of ECH dropwise. After dropping, keep warm until the pH value of the system reaches the peak value of 9.5. At this time, the system is a homogeneous system, which lasts for 4 hours. Then, turn to room temperature and react at 25°C for 2.5 hours. When the pH value of the reaction system drops to 7.8, the reaction ends; the catalyst is removed by filtration to obtain the crude product, and the crude product is continuously added with 1 times the volume of deionized water, and the vacuum degree is controlled at 750mmHg. Vacuum azeotropic distillation at 60°C to obtain solid content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com