Pellet of celery seed extract and preparation method thereof

A technology of celery seed extract and celery seed, applied in the field of medicine, can solve problems such as low yield of pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, the preparation of pellet

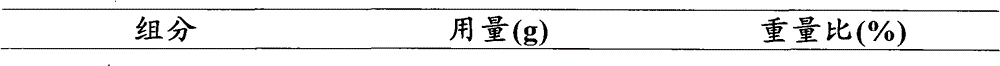

[0063] Prescription ratio:

[0064]

[0065]

[0066] Prepare as follows:

[0067] (1) Take the ethanol extract of celery seed according to the prescription ratio, add auxiliary materials such as microcrystalline cellulose and crospovidone, pulverize and mix;

[0068] (2) adding povidone aqueous solution as binder;

[0069] (3) The pellets were prepared by extrusion-spheronization. The mixed material is extruded into strips at the extrusion speed of 10-40r / min, and the amount of adhesive added is controlled to control the length of the extruded strips; The extrudate is cut off at a rotating speed, and then spheronized at a rotating speed of 30-50Hz for 10-20 minutes to obtain pellets. Move it into a drying room for drying. The drying condition is 30±2°C and the drying time is 12 hours. After drying, it is packaged.

Embodiment 2

[0070] Embodiment 2, the preparation of pellet

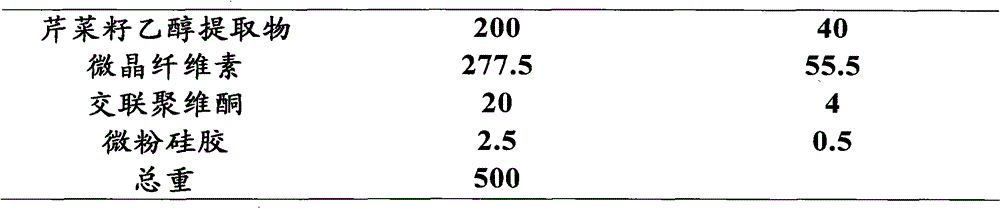

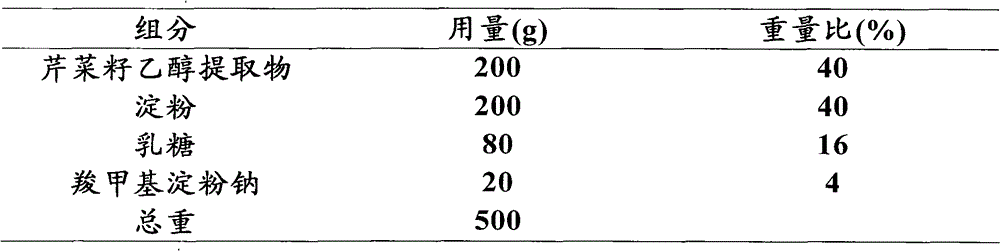

[0071] Prescription ratio:

[0072]

[0073] Prepare as follows:

[0074] (1) Take the celery seed ethanol extract according to the prescription ratio, add starch, lactose, carboxymethyl starch sodium and other auxiliary materials, pulverize and mix;

[0075] (2) adding the ethanol solution of ethyl cellulose as binder;

[0076](3) The pellets were prepared by extrusion-spheronization. The mixed material is extruded into strips at the extrusion speed of 10-40r / min, and the amount of adhesive added is controlled to control the length of the extruded strips; The extrudate is cut off at a rotating speed, and then spheronized at a rotating speed of 30-50Hz for 10-20 minutes to obtain pellets. Move it into a drying room for drying, the drying condition is 30±2°C, the drying time is 12 hours, and it is packaged after drying.

Embodiment 3

[0077] Embodiment 3, the preparation of pellet

[0078] Prescription ratio:

[0079]

[0080] Prepare as follows:

[0081] (1) Take the ethanol extract of celery seed according to the prescription ratio, add microcrystalline cellulose, dextrin, croscarmellose sodium and other auxiliary materials, pulverize and mix;

[0082] (2) adding an aqueous solution of hypromellose as a binding agent;

[0083] (3) The pellets were prepared by extrusion-spheronization. The mixed material is extruded into strips at the extrusion speed of 10-40r / min, and the amount of adhesive added is controlled to control the length of the extruded strips; The extrudate is cut off at a rotating speed, and then spheronized at a rotating speed of 30-50Hz for 10-20 minutes to obtain pellets. Move it into a drying room for drying, the drying condition is 30±2°C, the drying time is 12 hours, and it is packaged after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com