Aerobic granular sludge culture method suitable to low-concentration domestic sewage

A technology for aerobic granular sludge and domestic sewage, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Long mud time and other problems, to achieve the effect of good sedimentation, good sedimentation, and shortening the incubation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

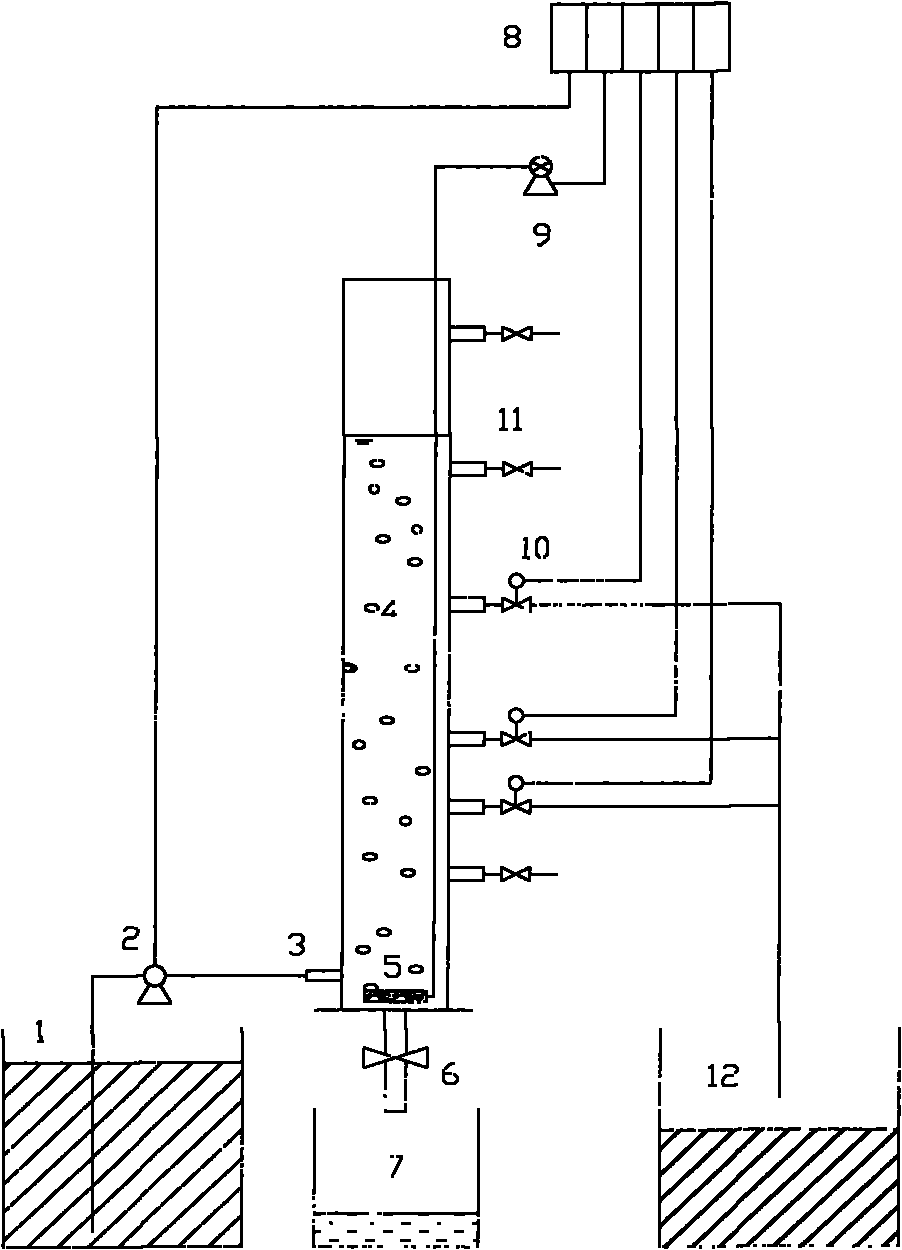

[0030] (1) Bioreactor: The reactor is made of plexiglass, 120cm high, 8cm internal diameter, and 5.5L effective volume. The air enters the reactor through a microporous aeration head installed in the center of the bottom of the reactor by the air pump, and the airflow formed pushes the liquid and granular sludge in the reactor upward, and the water outlet is located in the middle of the reactor. The water intake, aeration, settlement and drainage time of the reactor are all automatically controlled by the time relay. The whole experimental setup as figure 1 shown.

[0031] (2) Source of inoculated sludge and domestic sewage: Take the activated sludge from the secondary sedimentation tank of an urban sewage treatment plant, settle for 30 minutes, remove the supernatant, add fresh inorganic salt culture solution, expose to air for 2 hours, settle again for 30 minutes and remove the supernatant liquid. The concentrated sludge is added to the reactor. The initial sludge concen...

Embodiment 2

[0035] (1) Bioreactor: The reactor is made of plexiglass, with a height of 100cm and an inner diameter of 6cm. The air enters the reactor through a microporous aeration head installed in the center of the bottom of the reactor by an air pump, and the formed airflow pushes the liquid and the inside of the reactor. The granular sludge moves upwards, and the water outlet is located in the middle of the reactor. The water intake, aeration, settlement and drainage time of the reactor are all automatically controlled by the time relay.

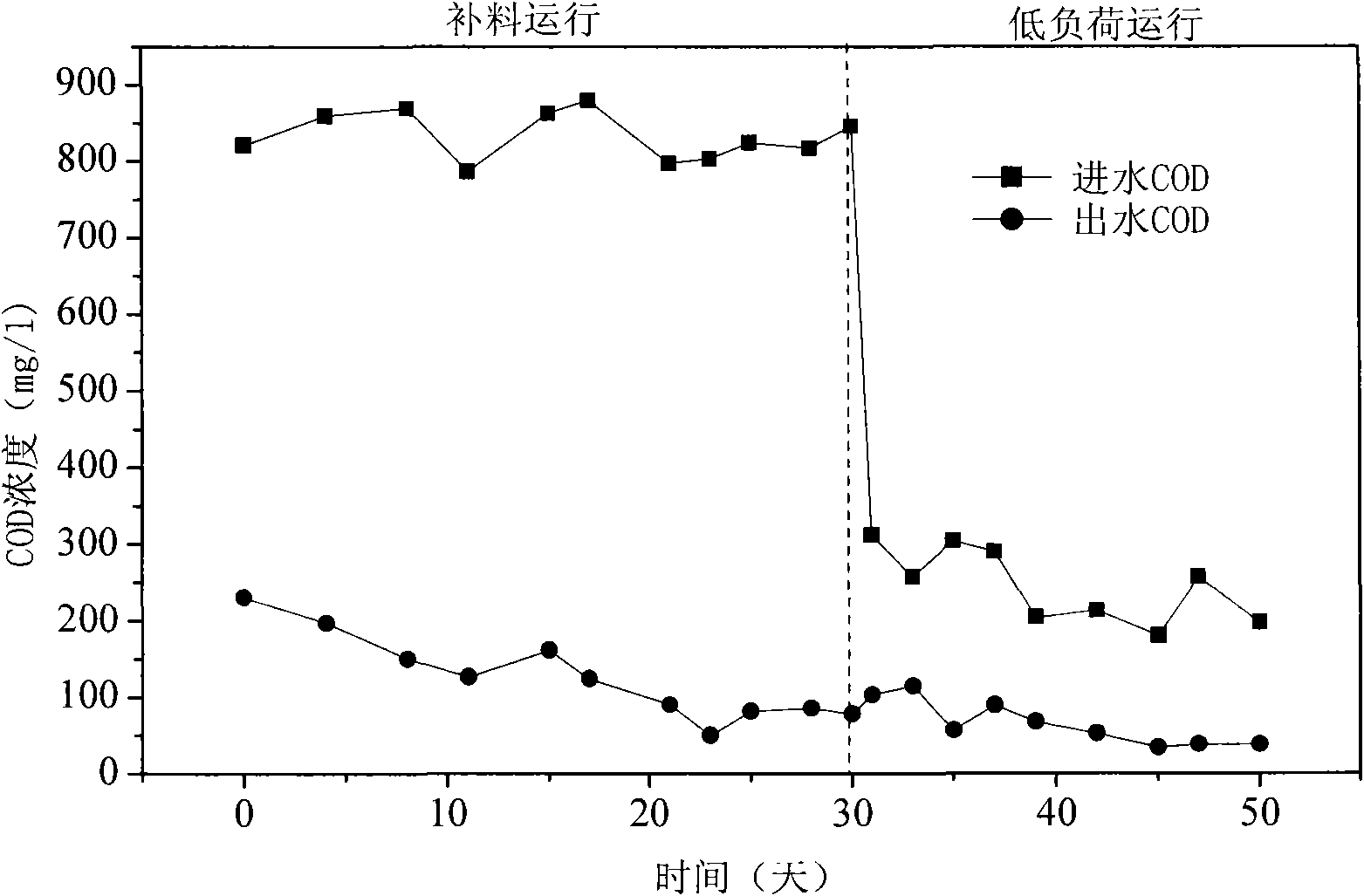

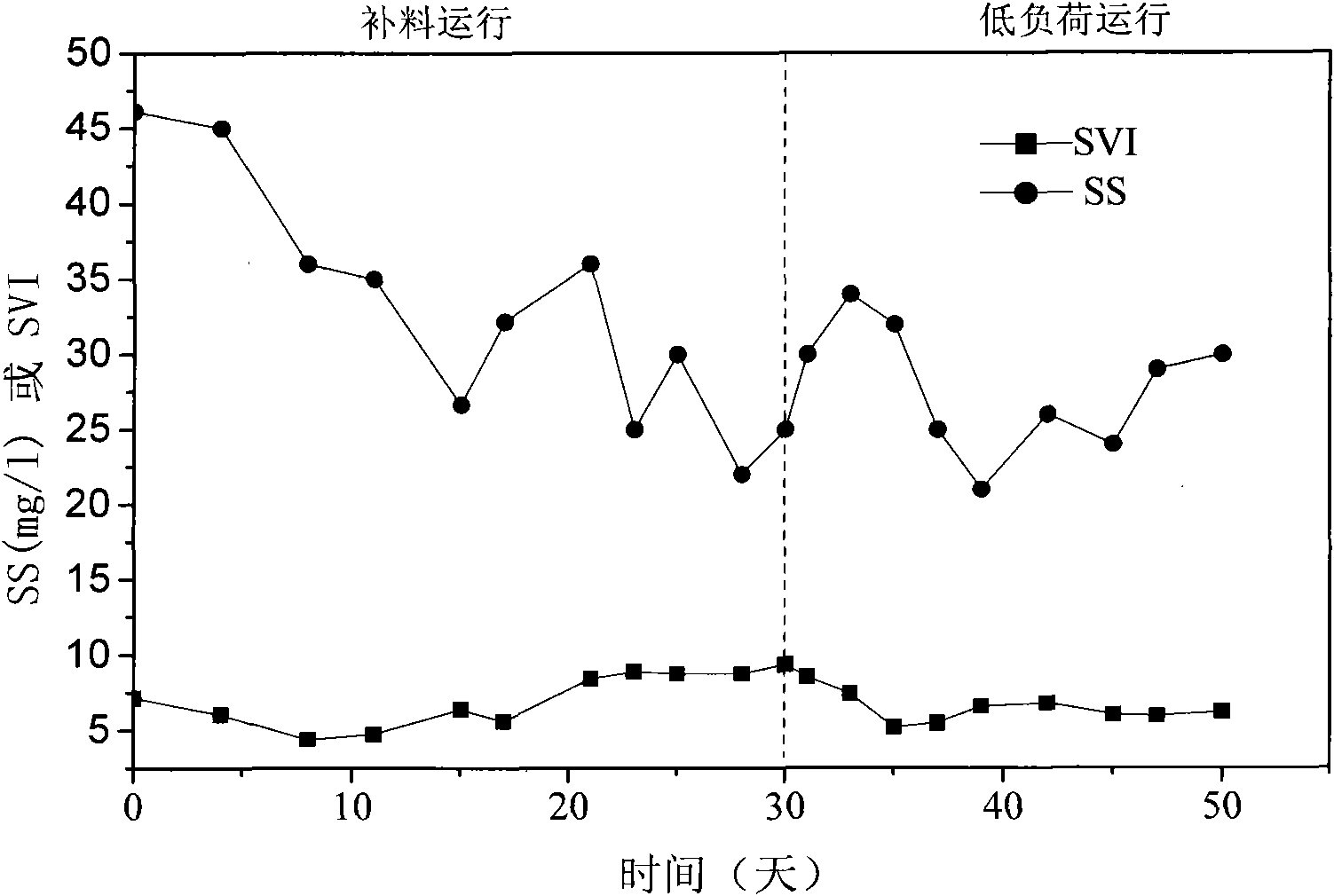

[0036] (2) Source of inoculated sludge and domestic sewage: Take the activated sludge from the secondary sedimentation tank of an urban sewage treatment plant, settle for 30 minutes, remove the supernatant, add fresh inorganic salt culture solution, expose to air for 2 hours, settle again for 30 minutes and remove the supernatant liquid. The concentrated sludge is added to the reactor. The initial sludge concentration inoculum is about 7gMLSS / L. ...

Embodiment 3

[0040] (1) Bioreactor: The height of the reactor is 150cm, the inner diameter is 8cm, a microporous aeration head is installed in the center of the bottom, and the water inlet and outlet are respectively located at the bottom and upper part of the reactor. The water intake, aeration, settlement and drainage time of the reactor are all automatically controlled by the time relay.

[0041] (2) Source of inoculated sludge and domestic sewage: Take the activated sludge from the secondary sedimentation tank of an urban sewage treatment plant, settle for 30 minutes, remove the supernatant, add fresh inorganic salt culture solution, expose to air for 2 hours, settle again for 30 minutes and remove the supernatant liquid. The concentrated sludge is added to the reactor. The initial sludge concentration inoculum is about 8gMLSS / L. The domestic sewage is domestic sewage in a city, and the water quality indicators are as follows (mg / L): BOD: 80-135, COD: 160-250, TN: 15-30, NH 4 + -N:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com