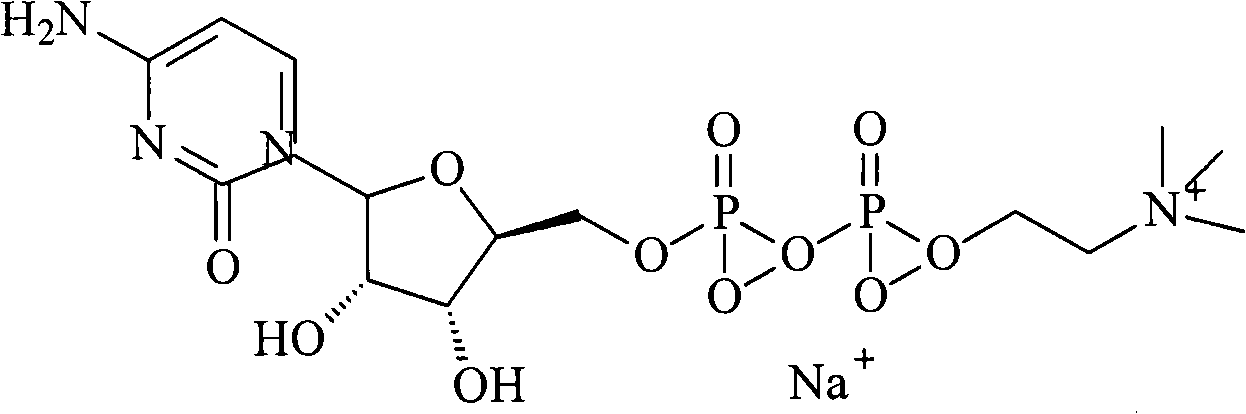

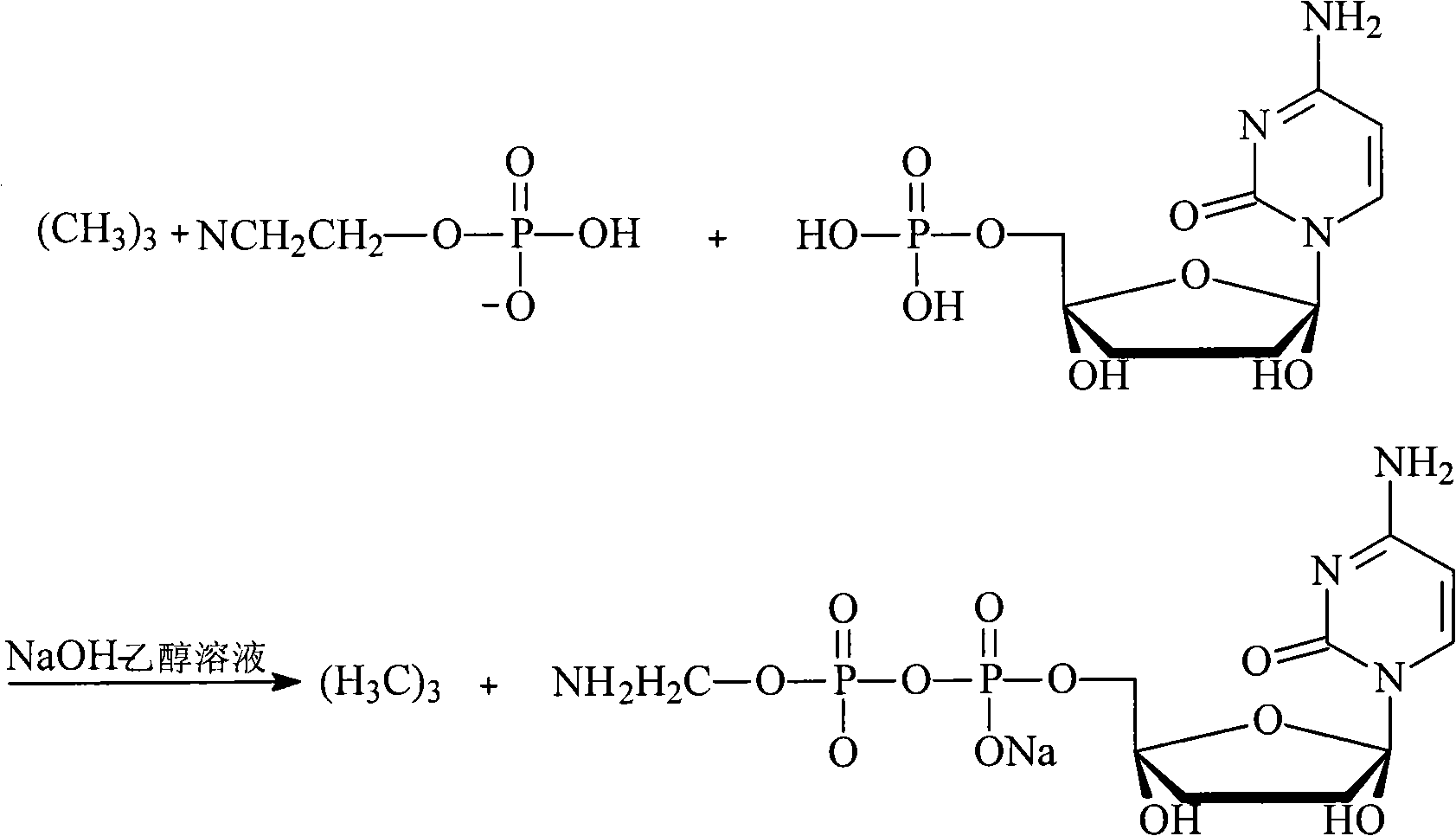

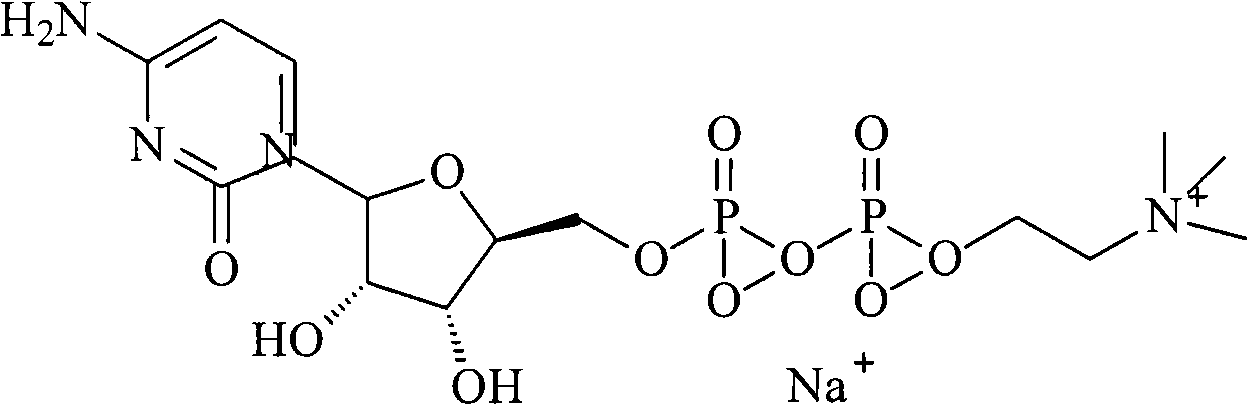

Citicoline sodium compound and new method thereof

A technology of citicoline sodium and citicoline, which is applied in the medical field, can solve the problems of undisclosed purification of citicoline sodium compounds, and achieve the effects of simple and easy process, high yield and optimized product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Purification of Citicoline Sodium

[0036] (1) Dissolve 100g of crude citicoline sodium with a purity of 96.8% in 120ml of water, heat for 10min, add 0.24g of activated carbon, keep at 60℃ and stir for 10min, filter and decarburize, and collect the filtrate;

[0037] (2) Slowly add 1mol / L hydrochloric acid to the obtained filtrate, stir the reaction until the pH of the solution is 2.2, and let it stand overnight in refrigeration to produce citicoline precipitation, and suction filtration to obtain 89.5g of citicoline;

[0038] (3) Put the 89.5g citicoline obtained in the previous step on the column, and apply the stationary phase filler to a preparative chromatographic column selected from silica gel for separation and purification, with a volume ratio of 1:3 chloroform and pH 9.0 hydroxide The mixed solution of sodium solution is the mobile phase for elution; the flow rate is 3.8ml / min, the column temperature is 35°C; the fractions are collected in sections, and the...

Embodiment 2

[0040] Example 2 Purification of Citicoline Sodium

[0041] (1) Dissolve 100g of crude citicoline sodium with a purity of 96.8% in 120ml of water, heat for 30min, add 0.6g of activated carbon, keep at 60℃ and stir for 20min, filter and decarburize, and collect the filtrate;

[0042] (2) Slowly add 1.5 mol / L phosphoric acid to the obtained filtrate, stir the reaction until the pH of the solution is 1.5, and let it stand overnight in cold storage to produce citicoline precipitation, and suction filtration to obtain 89.8 g of citicoline;

[0043] (3) The 89.8g citicoline obtained in the previous step was applied to the column, and the stationary phase filler was selected from the preparative chromatographic column of alumina for separation and purification. The volume ratio was 1:3 chloroform and pH 8.0 carbonic acid The mixed solution of sodium hydrogen solution is the mobile phase for elution; the flow rate is 3.0ml / min, the column temperature is 30°C; the fractions are collected in s...

Embodiment 3

[0045] Example 3 Purification of Citicoline Sodium

[0046] (1) Dissolve 100g of crude citicoline sodium with a purity of 96.8% in 120ml of water, heat for 20min, add 0.48g of activated carbon, keep at 60℃ and stir for 30min, filter and decarburize, and collect the filtrate;

[0047] (2) Slowly add 2.0 mol / L of oxalic acid to the obtained filtrate, and stir the reaction until the pH of the solution is 3.0 to produce citicoline precipitation, and suction filtration to obtain 89.2 g of citicoline;

[0048] (3) The 89.2g citicoline obtained in the previous step was applied to the column, and the stationary phase filler was selected from the preparative chromatographic column of alumina for separation and purification. The volume ratio was 1:3 chloroform and pH 10.0 hydrogen. The mixed solution of sodium oxide solution is the mobile phase for elution; the flow rate is 5.0ml / min, the column temperature is 35°C; the fractions are collected in sections, and the eluents with a content greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com