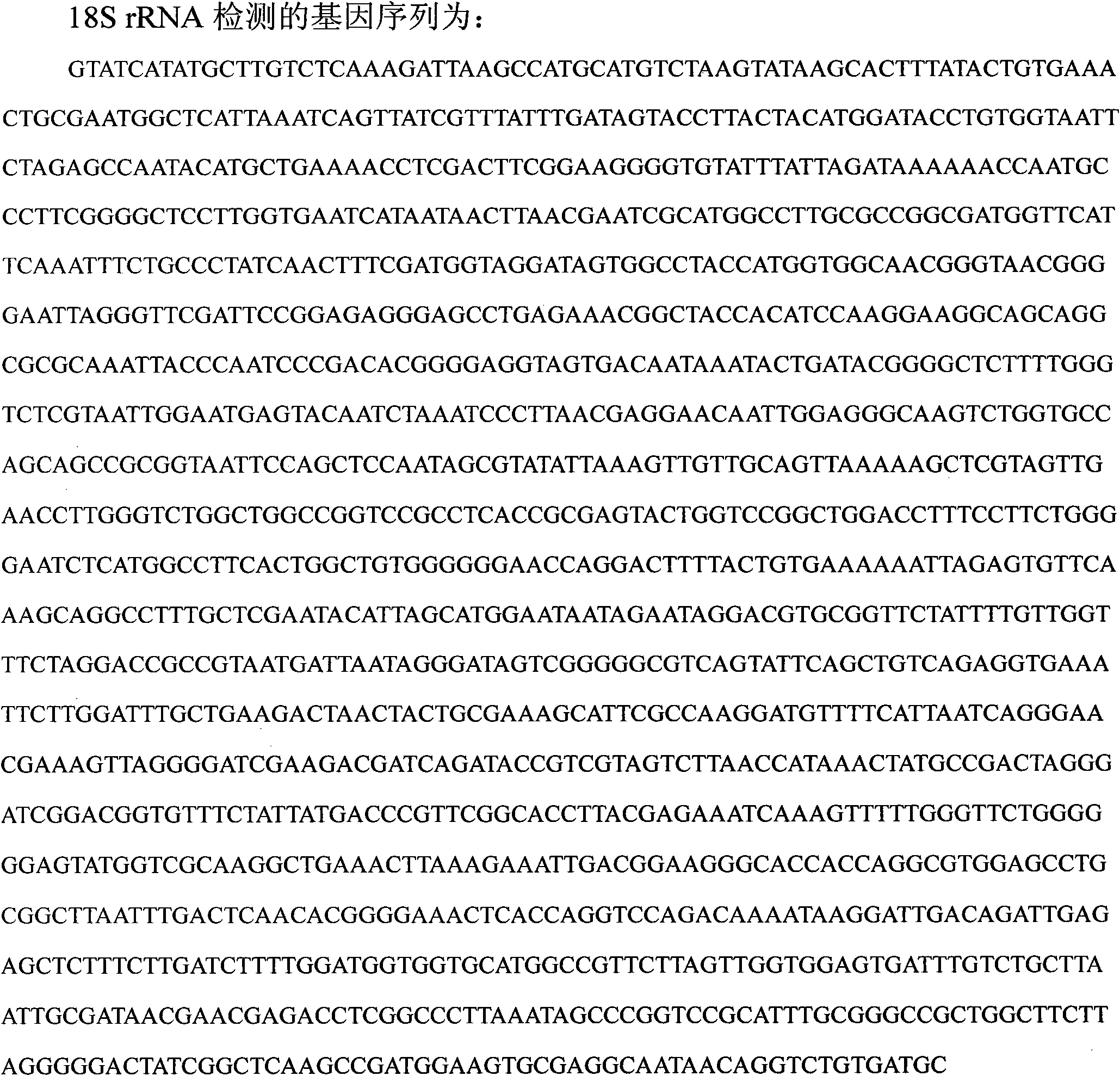

Liquid fermentation method for producing salt-tolerant cellulase from sea aspergillus niger

A technology of marine Aspergillus niger and cellulase, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, enzymes, etc., to achieve the effects of stable enzyme activity, easy control and amplification, and simple culture process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) A marine Aspergillus niger was screened from the soil at a depth of 10m off the coast of the East China Sea;

[0035] 2) Aspergillus niger was inoculated on PDA medium, cultured at 40°C for 60 hours to obtain slant spores, and the slant spores were stored at 4°C;

[0036] 3) The slant spores were inoculated in PDA-1 medium, and cultured at 40° C. for 60 hours to obtain activated spores;

[0037] 4) Put 60g of eggplant bottle slant culture medium into a 250ml eggplant bottle and compact it into a slant, seal the mouth of the bottle with 8 layers of gauze to obtain the slant of the eggplant bottle, inoculate the activated spores on the slant of the eggplant bottle, and culture at 42°C for 74 hours to obtain Eggplant bottle slant spores for expansion; the composition of eggplant bottle slant expansion culture medium is: three-layer gauze filtrate 80mL or 100mL or 120mL of potato artificial seawater boiled for 30min, glucose 2g, straw powder 50g; the composition of artif...

Embodiment 2

[0041] 1) A marine Aspergillus niger was screened from the soil at a depth of 10m off the coast of the East China Sea;

[0042] 2) Aspergillus niger was inoculated on PDA medium, cultured at 40°C for 60 hours to obtain slant spores, and the slant spores were stored at 4°C;

[0043] 3) The slant spores were inoculated in PDA-1 medium, and cultured at 40° C. for 60 hours to obtain activated spores;

[0044] 4) Put 60g of eggplant bottle slant culture medium into a 250ml eggplant bottle and compact it into a slant, seal the mouth of the bottle with 8 layers of gauze to obtain the slant of the eggplant bottle, inoculate the activated spores on the slant of the eggplant bottle, and culture at 42°C for 74 hours to obtain Eggplant bottle slant spores for expansion; the composition of eggplant bottle slant expansion culture medium is: 100mL of three-layer gauze filtrate boiled in artificial seawater for 30min, 1g or 2g or 6g of glucose, 50g of straw powder; the composition of artifici...

Embodiment 3

[0047] 1) A marine Aspergillus niger was screened from the soil at a depth of 10m off the coast of the East China Sea;

[0048] 2) Aspergillus niger was inoculated on PDA medium, cultured at 40°C for 60 hours to obtain slant spores, and the slant spores were stored at 4°C;

[0049] 3) The slant spores were inoculated in PDA-1 medium, and cultured at 40° C. for 60 hours to obtain activated spores;

[0050] 4) Put 60g of eggplant bottle slant culture medium into a 250ml eggplant bottle and compact it into a slant, seal the mouth of the bottle with 8 layers of gauze to obtain the slant of the eggplant bottle, inoculate the activated spores on the slant of the eggplant bottle, and culture at 42°C for 74 hours to obtain Eggplant bottle slant spores for expansion; the composition of the eggplant bottle slant expansion culture medium is: three layers of gauze filtrate 100mL, glucose 2g, rice straw powder 10g or 50g; artificial seawater is composed of: NaCl 29.8g, MgSO 4 5.4g, KCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com