Device for purifying and enriching inert gases and use method

An inert gas, enrichment technology, applied in measurement devices, sample preparation for testing, instruments, etc., can solve problems such as inability to use inert gas content analysis, lack, lack of quadrupole mass spectrometers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 - the embodiment of the device of the present invention

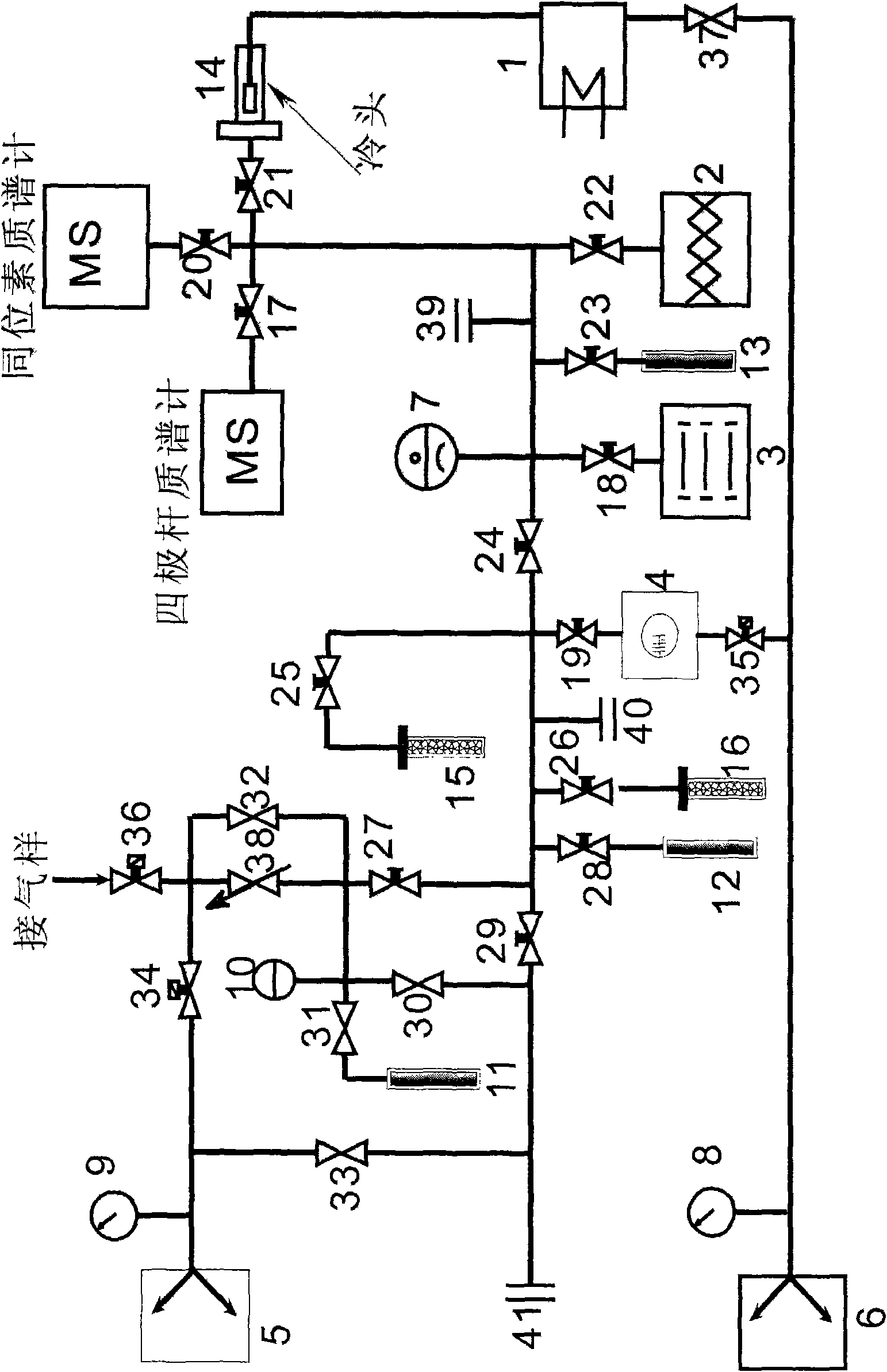

[0050] See figure 1 : figure 1 Middle: V1~V3 DN40 all-metal ultra-high vacuum angle valve; V4~V13 DN16 all-metal ultra-high vacuum angle valve; V14~V17 DN16 high vacuum angle valve; V18~V20 electromagnetic isolation valve; V21 1 / 4 inch vacuum pressure valve ;V22 sapphire fine-tuning valve; G1, G2, G4 compound vacuum gauge; G3 CDG film vacuum gauge; C1~C3 liquid nitrogen activated carbon cold trap; C4 ultra-low temperature cold trap; P1 cryopump; P2 zirconium aluminum suction; P3 ion pump; P4 Molecular pumps, P5~P6 mechanical pumps; F1~F3 flange blind plates are connected by stainless steel pipelines with an outer diameter of 14mm and an inner diameter of 10mm. The equipment flow and connection relationship are as follows: figure 1 shown. The interface is hard-sealed with flange and oxygen-free copper gasket to ensure no air leakage.

Embodiment 2

[0051] Embodiment 2 - the embodiment of the inventive method

[0052] First, the inert gas purification and enrichment device is evacuated to a high vacuum (5.0×10 -8 Pa), and then open the valve (V21) to send sample gas (natural gas, rock desorption gas) into the system. Control the injection volume by adjusting the fine-tuning valve (V22), observe the G3 membrane vacuum gauge and record the injection pressure. Open the valve V13 and the sample gas enters the high-vacuum purification section to purify active gas successively in the activated carbon cold trap (C2) under liquid nitrogen medium, zirconium-based getter furnace (L2) at room temperature, and titanium sponge furnace (L1) at 800 °C.

[0053] After the active gas is removed from the sample gas, the inert gas is extracted. Open the valve V8 and the purified inert gas diffuses into the high vacuum analysis section, close V8 and open the zirconium aluminum getter pump to further inert gas. After the pressure gauge G1 ...

Embodiment 3

[0059] Embodiment 3——Comparative example

[0060] Compared with the all-metal rare gas purification and mass spectrometry system in Document 1, the inert gas in the gas in the volcanic area was analyzed, and the results are shown in Table 4.

[0061] Table 4 Comparison of noble gas results in a volcanic area in file 1

[0062] sample number

[0063] It can be seen from Table 4 that this analysis method can only obtain the isotope ratio of some inert gases, but cannot obtain the content of each component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com