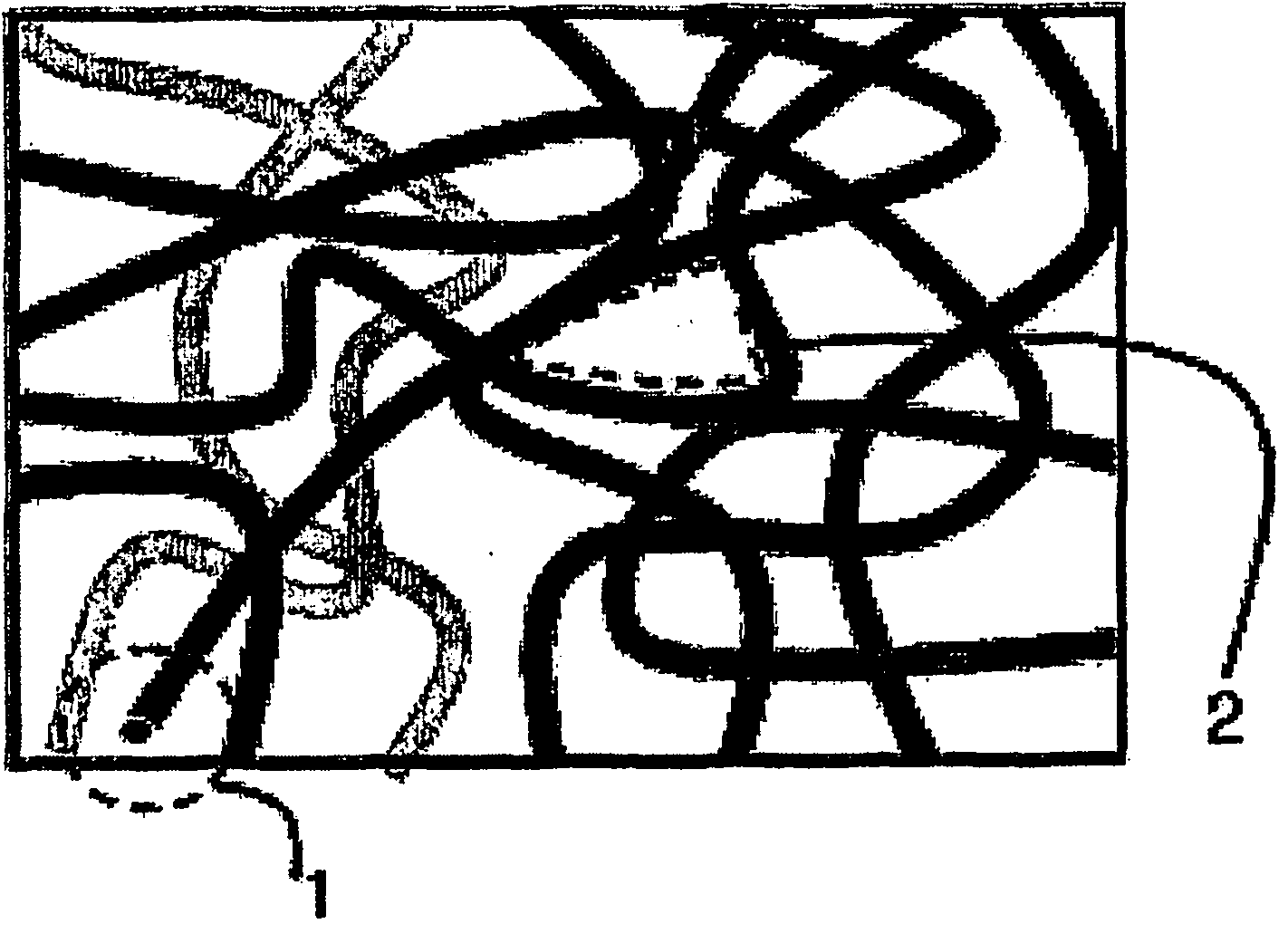

Dissolvable nano web porous film and method of preparing the same

A mesh-like porous and porous film technology, which is applied in the manufacture of rayon, medical preparations of non-active ingredients, sheet-like delivery, etc., can solve the problem that the film does not have enough anti-adhesive properties, and achieve excellent solubility and rapid display of treatment Effect, the effect of preventing bad smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

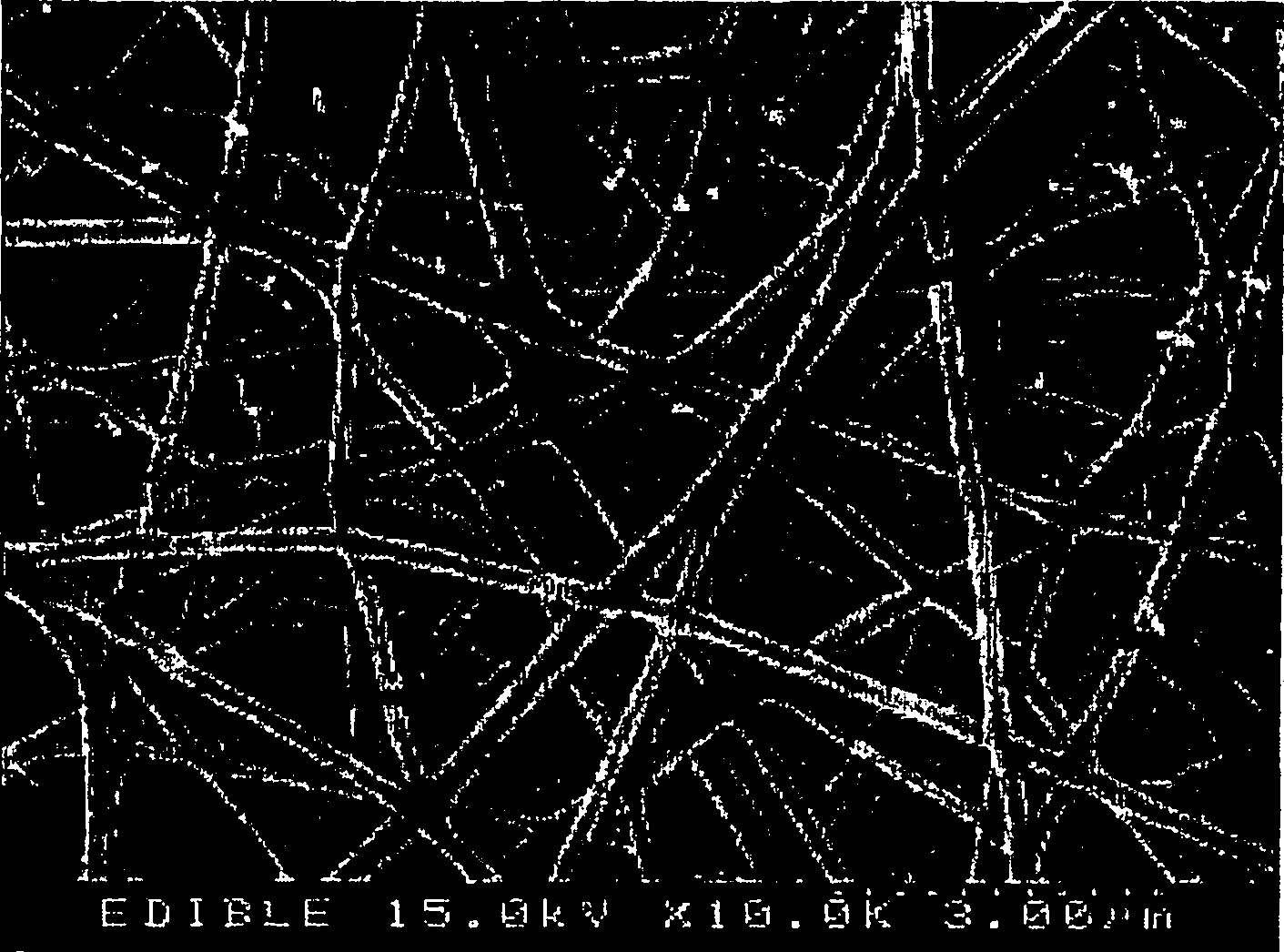

[0096] (1) Preparation of a polymer solution for forming a nano-network porous membrane

[0097] Add 1.5% by weight of microcrystalline cellulose to 70% by weight of distilled water, and disperse fully and uniformly at room temperature for about 10 minutes. 0.6% by weight of sucrose fatty acid ester was added to this solution and completely dissolved. Then, add 0.3% by weight of sorbitol, 0.8% by weight of propylene glycol and 0.4% by weight of glycerol to the resulting solution, heat to 70°C, slowly add 23% by weight of pullulan in the heated solution, and stir until completely dissolved In solution. The formed solution was heated to 80° C., 0.13 wt % carrageenan, 0.13 wt % carob gum (LBG) and 0.13 wt % xanthan gum were added to the heated solution to completely disperse and dissolve. After the resulting solution was cooled to 40° C., 0.46% by weight of aspartame, 0.04% by weight of acesulfame K, 0.3% by weight of malic acid, 2% by weight of menthol and 0.21% by weight of c...

Embodiment 2

[0112] Add 1.5% by weight of microcrystalline cellulose to 70% by weight of distilled water, and disperse fully and uniformly at room temperature for about 10 minutes. 0.6% by weight of sucrose fatty acid ester was added to this solution and completely dissolved. Then, add 0.3% by weight of sorbitol, 0.8% by weight of propylene glycol and 0.4% by weight of glycerol to the resulting solution, heat to 70°C, slowly add 23% by weight of pullulan in the heated solution, and stir until completely dissolved in solution. The formed solution was heated to 80° C., 0.1 wt % carrageenan, 0.1 wt % carob gum (LBG) and 0.1 wt % xanthan gum were added to the heated solution to completely disperse and dissolve. After the resulting solution was cooled to 40° C., 0.5% by weight of aspartame, 0.1% by weight of acesulfame K, 0.3% by weight of malic acid, 2% by weight of menthol and 0.2% by weight of citric acid were added to the solution, and then Stir until they are uniformly dispersed and comple...

Embodiment 3

[0116] Add 0.6% by weight of sucrose fatty acid ester to 71.41% by weight of distilled water, and disperse fully and uniformly at room temperature. Then, 0.3% by weight of sorbitol, 0.9% by weight of propylene glycol, and 0.4% by weight of glycerin were added to the solution, and heated to 70°C. 23% by weight of hydroxypropylmethylcellulose (HPMC) was slowly added to the heated solution, and stirred until completely dissolved in the solution. The formed solution was heated to 80° C., 0.1 wt % carrageenan, 0.1 wt % carob gum (LBG) and 0.1 wt % xanthan gum were added to the heated solution to completely disperse and dissolve. After the resulting solution was cooled to 40° C., 0.45% by weight of aspartame, 0.04% by weight of acesulfame K, 0.3% by weight of malic acid, 2% by weight of menthol and 0.3% by weight of citric acid were added to the solution, and then Stir until they are uniformly dispersed and completely dissolved, thus preparing a polymer solution. The porous membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com