Dyeing reclaimed water recycling process and equipment

A process and reclaimed water technology, which is applied in the field of water reuse in printing and dyeing wastewater, can solve the problems of high impact load of reverse osmosis treatment system, poor stability of ultrafiltration membrane, and high conductivity of effluent water, so as to reduce construction cost, reduce construction cost and operation cost, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

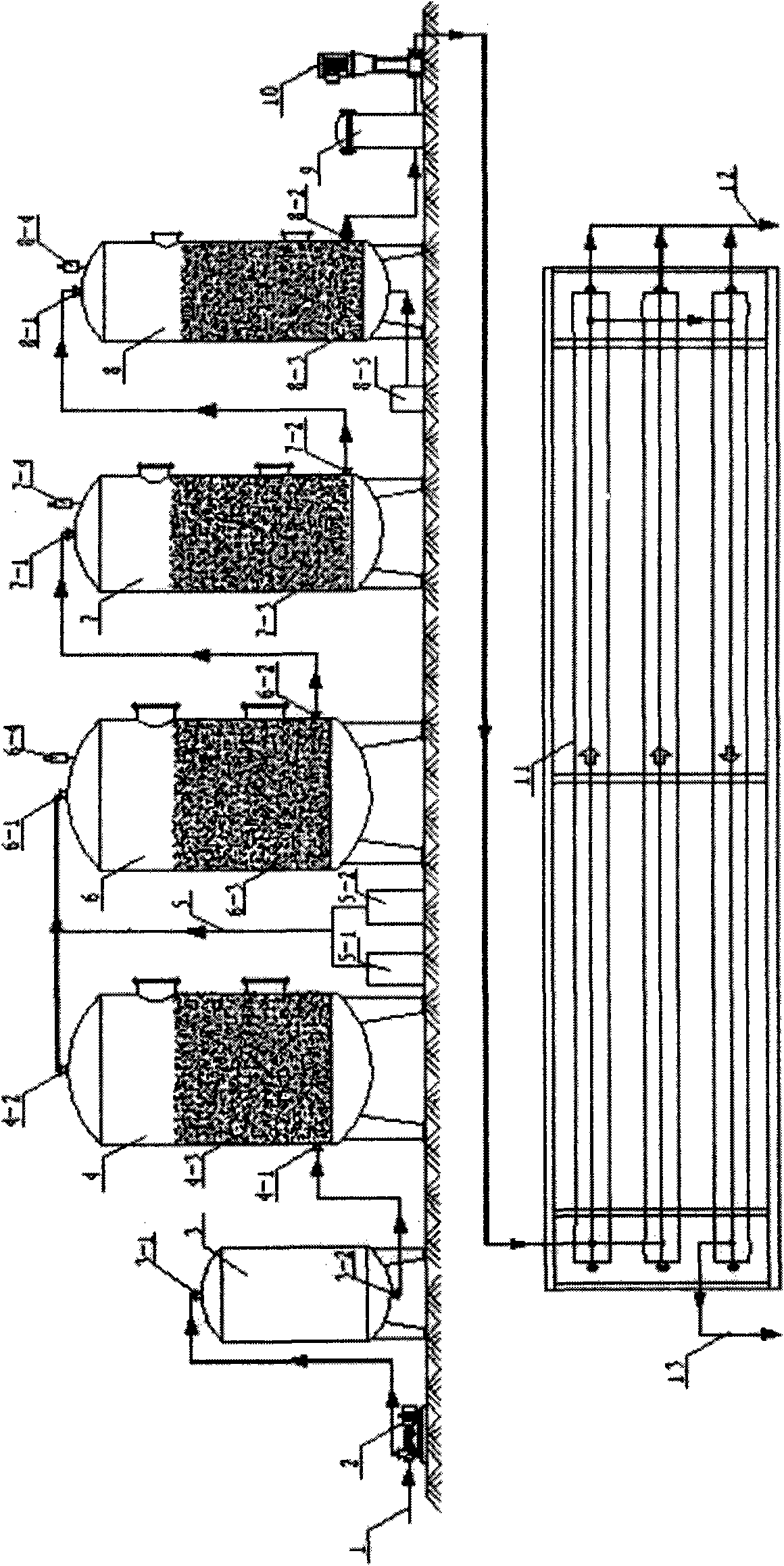

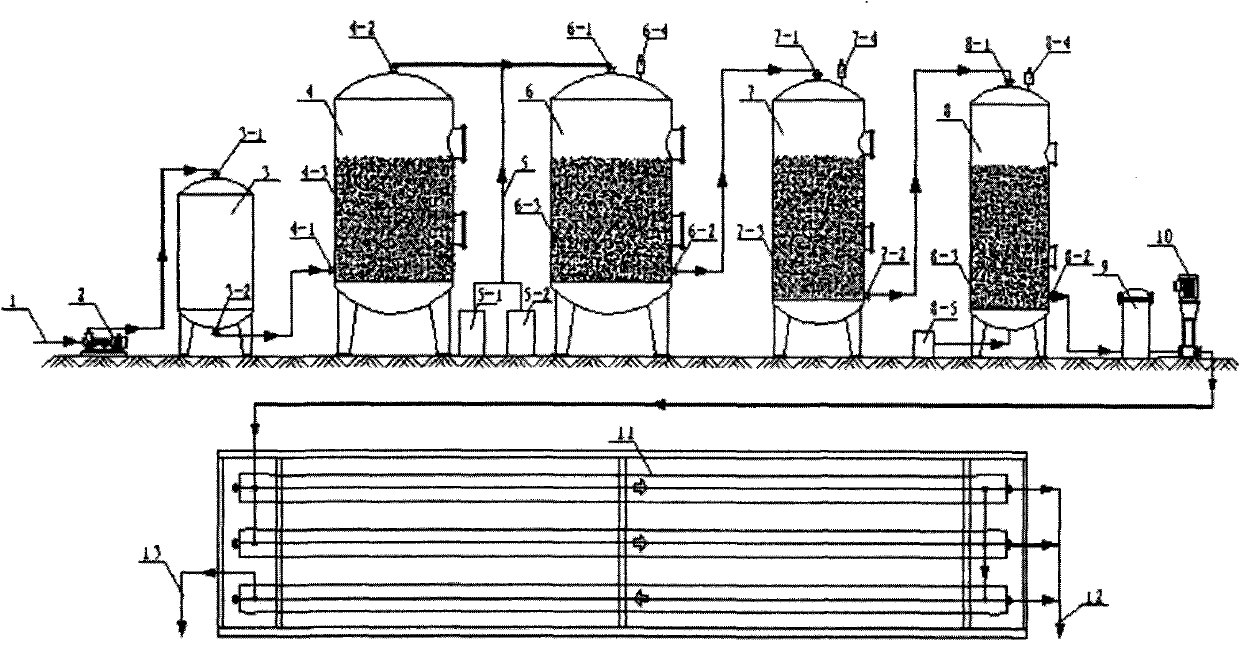

[0013] The present invention relates to a process and equipment for reusing water in printing and dyeing wastewater. The reclaimed water technology includes biological, chemical and physical effects on printing and dyeing wastewater, using biological filtration to treat printing and dyeing wastewater, adding flocculant 5-1 and Bactericide 5-2 ensures that the follow-up treatment process is carried out stably; described flocculant 5-1 is organic polymer flocculant or other medicament; described bactericide 5-2 is chlorine dioxide or other medicament; 3. The multi-media filter 6, activated carbon filter 7, and ion exchanger 8 are used as the pretreatment of the reverse osmosis device 11 to ensure that the water intake of the reverse osmosis treatment system meets or exceeds the water intake requirements and prolongs the service life.

[0014] Utilize a kind of water reuse process in printing and dyeing wastewater provided by the present invention, carry out in certain printing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com