Preparation method of continuous fiber reinforced metal matrix composite

A composite material and continuous fiber technology, applied in the field of metal matrix composite material preparation, can solve the problems of limited promotion and application, high cost, expensive reinforcement fiber, etc., and achieve the effect of high cooling rate, easy operation, and alleviating interface reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

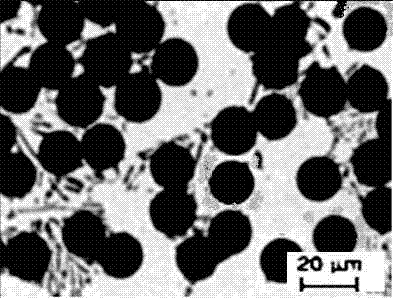

[0020] For the composite material to be prepared, carbon fiber with a diameter of 15 μm is selected as the reinforcing fiber, and 7050 aluminum alloy is selected as the matrix material.

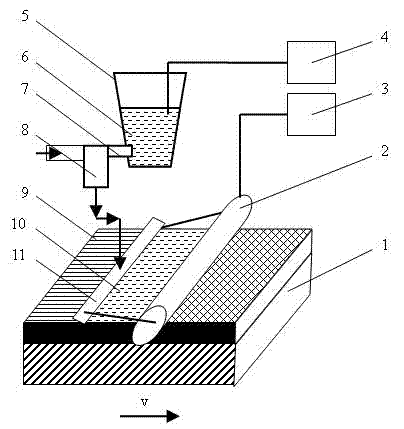

[0021] The equipment is evacuated to 1×10 -3Pa, the vacuum chamber is filled with argon gas of 20kPa as a protective atmosphere, and the aluminum alloy is melted in the crucible according to the composition ratio of 7050 aluminum alloy. After purification, the aluminum alloy melt is introduced into the blowing chamber through the guide hole, and the guide is closed at the same time Through the inert gas pipe at the upper end of the blowing chamber, the blowing gas of 50kPa is introduced to blow the 7050 aluminum alloy melt at 680°C onto the surface of the fast-moving copper substrate (500mm long and 200mm wide in the moving direction) from the nozzle. The horizontal moving speed of the aluminum alloy is 20000mm / s, the copper substrate is under the nozzle of the spray device, the vertical dist...

Embodiment 2

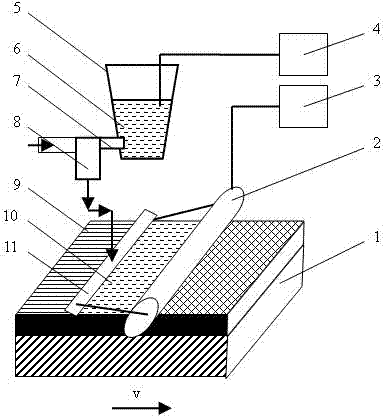

[0023] For the composite material to be prepared, SiC fiber with a diameter of 100 μm is selected as the reinforcing fiber, and 7055 aluminum alloy is selected as the matrix material.

[0024] The equipment is evacuated to 2×10 -3 Pa, the vacuum chamber is filled with argon gas of 40kPa as a protective atmosphere, and the aluminum alloy is melted in the crucible according to the composition ratio of 7055 aluminum alloy. After purification, the aluminum alloy melt is introduced into the blowing chamber through the guide hole, and the guide is closed at the same time. Through the inert gas pipe at the upper end of the blowing chamber, the blowing gas of 80kPa is passed into the blowing gas, and the 7055 aluminum alloy melt at 690°C is sprayed onto the surface of the fast-moving copper substrate (500mm long and 220mm wide in the moving direction) from the nozzle. The horizontal moving speed of 10000mm / s, the copper substrate is below the nozzle of the spray device, the vertical d...

Embodiment 3

[0026] The composite material to be prepared selects W fibers with a diameter of 150 μm as reinforcing fibers, Zr 41.25 Ti 13.75 Cu 12.5 Ni 10 Be 22.5 The bulk amorphous alloy is the base material.

[0027] The equipment is evacuated to 1×10 -3 Pa, the vacuum chamber is filled with 60kPa argon as a protective atmosphere, according to Zr 41.25 Ti 13.75 Cu 12.5 Ni 10 Be 22.5 The composition ratio of the bulk amorphous alloy is to melt the aluminum alloy in the crucible. After purification, the aluminum alloy melt is introduced into the blowing chamber through the guide hole. At the same time, the guide hole is closed, and the inert gas pipe at the upper end of the blowing chamber is passed into 120kPa. The blowing gas blows the 760°C bulk amorphous alloy melt from the nozzle to the surface of the fast-moving copper substrate (600mm long and 240mm wide in the moving direction), the horizontal moving speed of the copper substrate is 5000mm / s, and the copper substrate is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com