Device for thin film overlying photovoltaic and quick thermal treatment method

A rapid heat treatment and device technology, applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of expensive crystal materials, not being able to use for a long time, and low technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] According to an embodiment of the present invention, a method and structure for forming a semiconductor material for photovoltaic applications is provided. More specifically, the present invention provides a method for fabricating a thin film photovoltaic device that can be used in tandem cell configurations as well as in other cell configurations. By way of example only, the method is used to provide copper indium disulfide thin film material for high efficiency solar cell applications. However, it should be understood that the present invention has a wider range of applications. For example, the embodiments of the present invention can be used to form other semiconductor thin films or include iron sulfide, calcium sulfide, zinc selenide, etc., and such as zinc oxide, iron oxide, copper oxide, etc. multilayer structure of metal oxides.

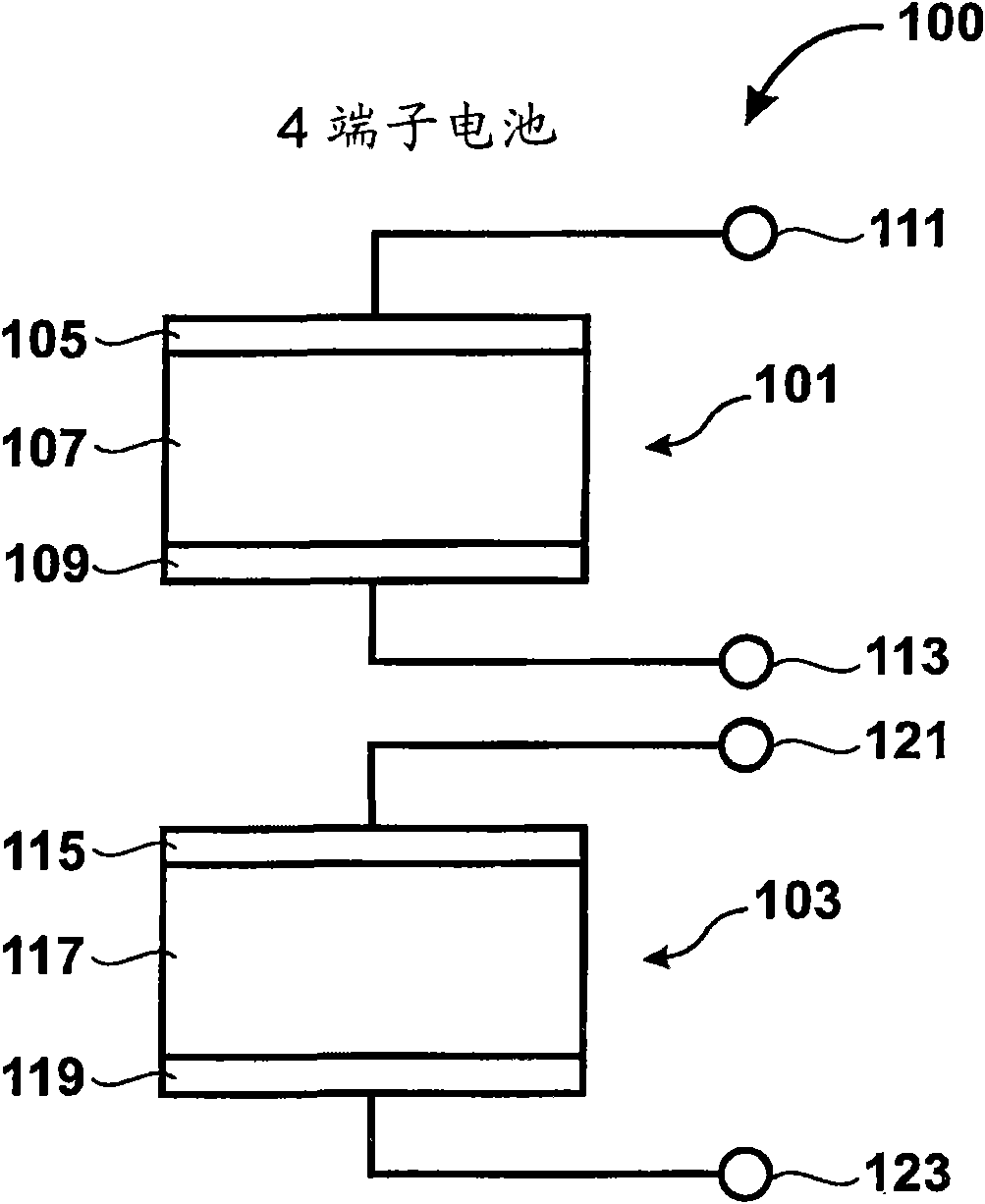

[0018] figure 1 is a simplified diagram of a tandem photovoltaic cell according to an embodiment of the invention. The illustratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com