Method for treating pure terephthalic acid refined wastewater

A technology of purified terephthalic acid and refined wastewater, which is applied in the comprehensive utilization of purified terephthalic acid wastewater, industrial wastewater treatment, and the treatment of purified terephthalic acid wastewater. It can solve the impact of membrane system operation, membrane modules Damage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

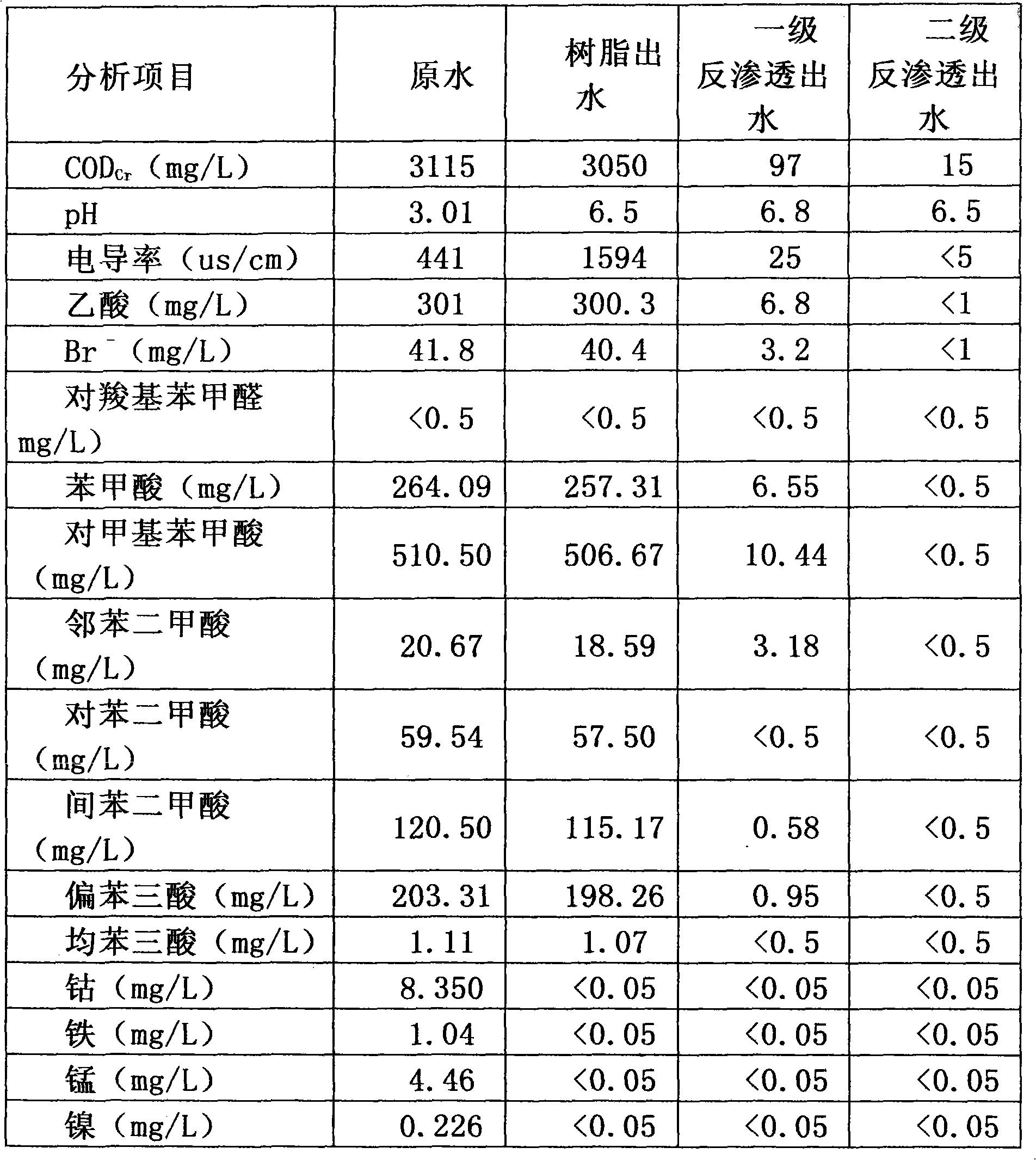

[0028] A petrochemical plant treats wastewater from a PTA production unit, with a treatment capacity of 5m 3 / h, the waste water is the waste water from the refining unit after separation of mother and solid, the water temperature is 55°C, and the indicators of various pollutants in the waste water are shown in Table 1:

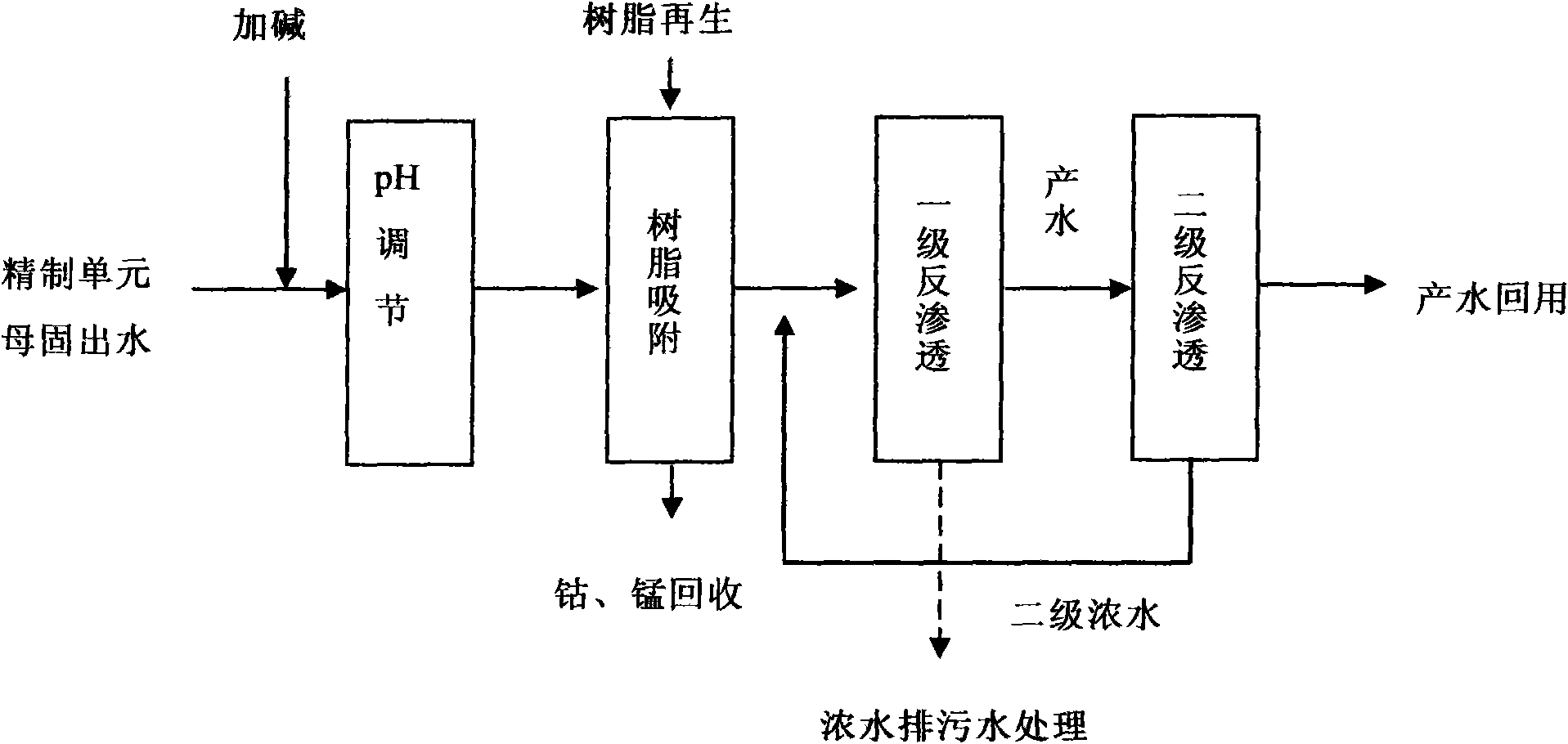

[0029] The waste water is treated as follows:

[0030] 1) First, add sodium hydroxide (27%) to the waste water to make the pH of the waste water reach 4.2, so as to dissolve the tiny suspended particles in the waste water, so that the waste water meets the requirements for subsequent use of the resin unit;

[0031] 2) After pH adjustment, the waste water enters the resin adsorption unit, and macroporous alloy resin is used to remove cobalt and manganese metal ions in the waste water. The volume of the resin is 5m 3 , the flow rate of the resin adsorption column is controlled at 10BV, and after the resin unit runs for 72 hours, 4% hydrochloric acid is used fo...

Embodiment 2

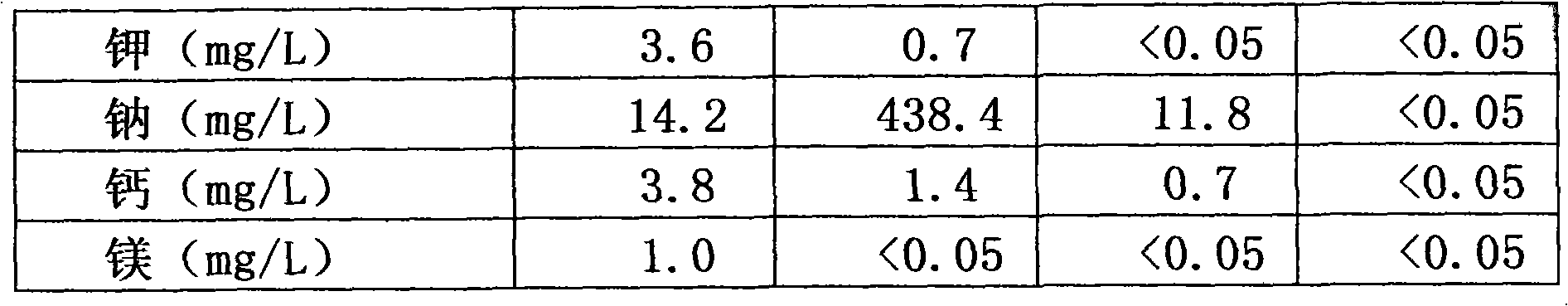

[0038] A petrochemical plant PTA production plant wastewater, wastewater treatment capacity 3m 3 / h, the waste water is the waste water from the refining unit after separation of mother and solid, the water temperature is 52°C, and the indicators of various pollutants in the waste water are shown in Table 2:

[0039] The waste water is treated as follows:

[0040] 1) First, add sodium carbonate (20%) to the waste water to make the pH of the waste water reach 4.8, so as to dissolve the tiny suspended particles in the waste water, so that the waste water meets the requirements for subsequent use of the resin unit;

[0041] 2) The wastewater after adjusting the pH enters the resin adsorption unit, and ion exchange resin is used to remove cobalt and manganese metal ions in the wastewater. The volume of the resin is 4m 3 , the flow rate of the resin adsorption column is controlled at 18BV, and after the resin unit runs for 60 hours, 5% hydrobromic acid is used for elution and rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com