Preparation method of potassium-sodium niobate leadless piezo-electric ferroelectric ceramic

A technology of lead-free piezoelectric and ferroelectric ceramics, applied in the field of functional ceramic environment-friendly materials, can solve the problems of poor piezoelectric performance and low density, and achieve excellent ferroelectric performance, high density, energy saving and production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

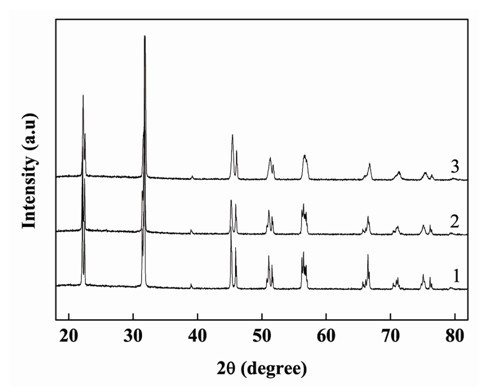

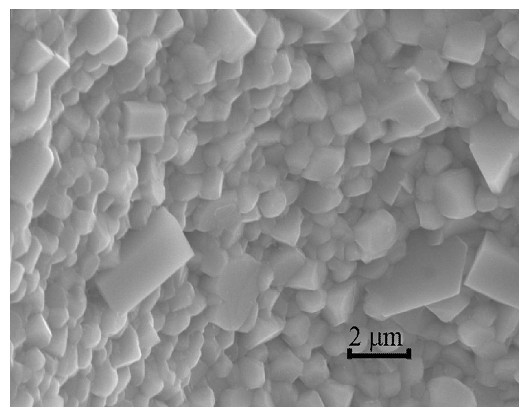

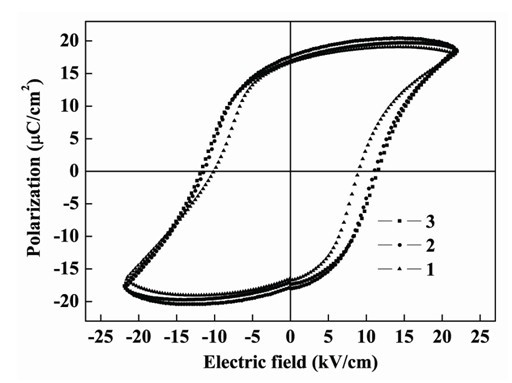

Embodiment 1

[0025] First, weigh 0.08mol of citric acid into a 500mL beaker, add 100mL of deionized water, and dissolve it under ultrasonic dispersion to form a transparent solution; then weigh 0.02mol of sodium nitrate, 0.02mol of potassium nitrate, and 0.04mol of niobium oxalate into the In the above solution, disperse with magnetic stirring, and heat at 50°C to promote dissolution to form a transparent solution. Adjust the pH value to 4.5 with ammonia water, and age the mixed solution for 6 hours. In the second step, the solution was evaporated to dryness in a water bath at 90° C. to remove moisture, and dried in an oven at 160° C. until a black xerogel was formed. The third step is to grind the xerogel, heat-treat it in an air atmosphere at 600°C for 5 hours in a muffle furnace, remove organic matter to obtain a precursor powder, then grind the precursor powder, and press it with a tablet machine at 30Mp. Sintered at 1000°C for 1.2 hours in a Furnace to obtain Na 0.5 K 0.5 NbO 3 cer...

Embodiment 2

[0032] First, weigh 0.08mol of citric acid into a 500mL beaker, add 80mL of deionized water, and dissolve it under ultrasonic dispersion to form a transparent solution; then weigh 0.02mol of sodium nitrate, 0.02mol of potassium nitrate, and 0.04mol of niobium oxalate into the In the above solution, disperse with magnetic stirring, and heat at 50°C to promote dissolution to form a transparent solution. Adjust the pH value to 4 with ammonia water, and age the mixed solution for 6 hours. In the second step, the solution was evaporated to dryness in a water bath at 90° C. to remove moisture, and dried in an oven at 160° C. until a black xerogel was formed. The third step is to grind the xerogel, and heat-treat it in an air atmosphere at 600°C for 5 hours in a muffle furnace to remove organic matter to obtain a precursor powder, then grind the precursor powder, and press the tablet machine at 20Mp, Sintered at 900°C for 1 hour in a Furnace to obtain Na 0.5 K 0.5 NbO 3 ceramics. ...

Embodiment 3

[0039] First, weigh 0.08mol of citric acid into a 500mL beaker, add 120mL of deionized water, and dissolve it under ultrasonic dispersion to form a transparent solution; then weigh 0.02mol of sodium nitrate, 0.02mol of potassium nitrate, and 0.04mol of niobium oxalate into the In the above solution, disperse with magnetic stirring, and heat at 50°C to promote dissolution to form a transparent solution. Adjust the pH value to 4 with ammonia water, and age the mixed solution for 6 hours. In the second step, the solution was evaporated to dryness in a water bath at 90° C. to remove moisture, and dried in an oven at 160° C. until a black xerogel was formed. The third step is to grind the xerogel and heat-treat it in an air atmosphere at 600°C for 5 hours in a muffle furnace to remove organic matter to obtain a precursor powder. Sintered at 800°C for 2 hours in a Furnace to obtain Na 0.5 K 0.5 N b o 3 ceramics. In the fourth step, in order to measure the electrical properties,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com