Vinyl acetate-ethylene copolymer emulsion (VAE emulsion) and synthesis method thereof

A technology of ethylene copolymerization emulsion and vinyl acetate, which is applied in the field of fine particle size VAE emulsion and its preparation, can solve problems such as not being able to meet the needs of the market, and achieve the effects of fast speed, easy industrialization, and short polymerization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

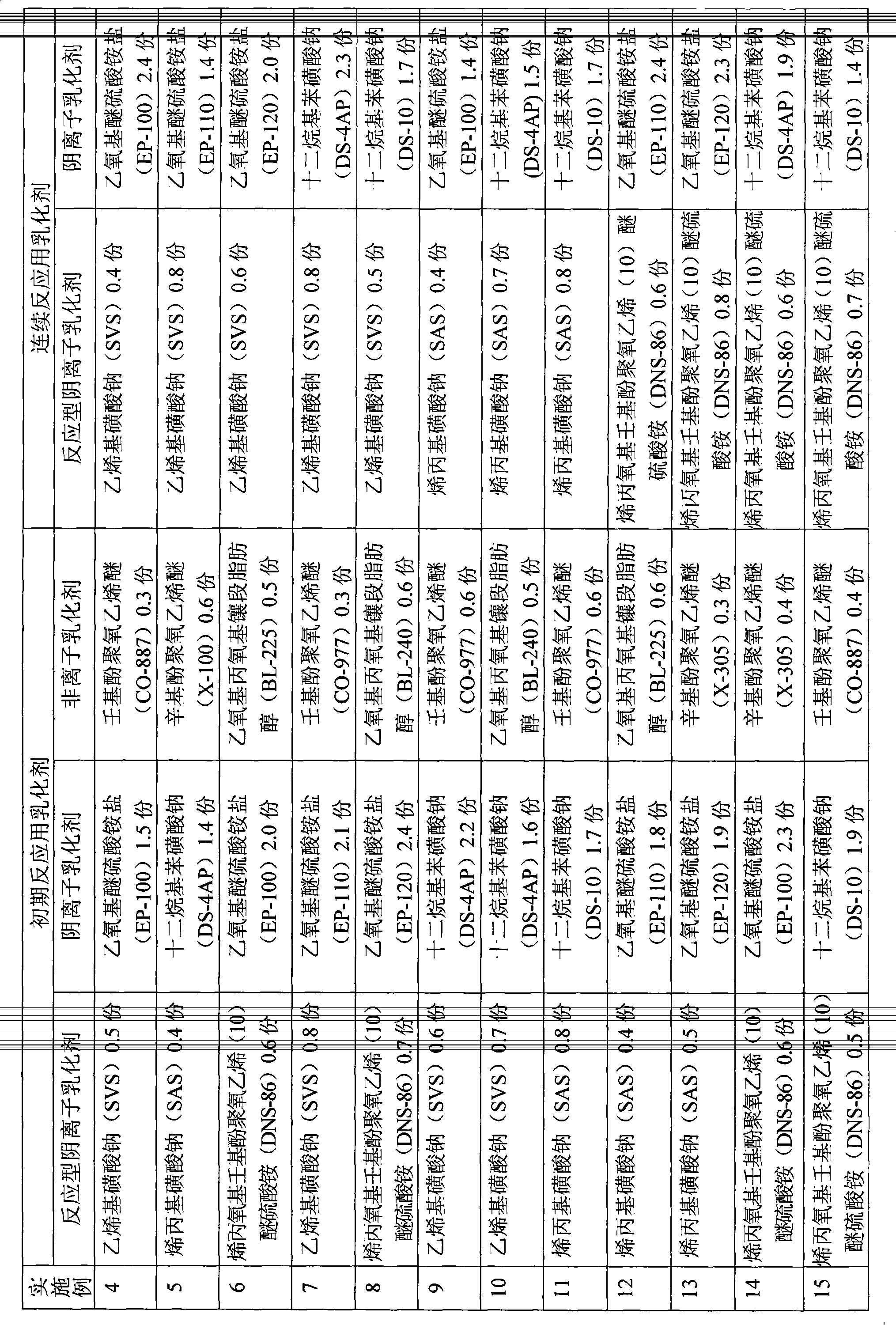

Examples

Embodiment 1

[0038] 1. Preparation of raw materials

[0039] (1) Add 2.5 parts of emulsifier for initial reaction and 42 parts of deionized water into the reactor, start stirring, heat up after fully mixing, add 0.1 part of sodium bisulfite to make it completely dissolved; wherein the emulsifier for initial reaction Specifically, 0.5 parts of reactive anionic emulsifier of sodium vinylsulfonate SVS, 1.7 parts of anionic emulsifier of sodium dodecylbenzenesulfonate DS-10 and nonionic emulsifier of nonylphenol polyoxyethylene ether Co-887 0.3 parts.

[0040] (2) Add 0.1 part of ammonium persulfate, 1.5 parts of deionized water and stir for 15 minutes to make initial initiator solution in the initial initiator tank, add 0.2 part of ammonium persulfate, 0.1 part of sodium bicarbonate, 2.0 parts of sodium bicarbonate in the continuous initiator tank One part of emulsifier for continuous reaction and 8 parts of deionized water were stirred for 20min to be mixed with continuous initiator solutio...

Embodiment 2

[0048] Get 5.2 parts of emulsifiers (2.8 parts of emulsifiers for initial stage reaction, 2.4 parts of emulsifiers for continuous reactions; wherein said initial reaction emulsifiers are specifically 0.6 parts of reactive anionic emulsifiers of sodium vinyl sulfonate (SVS), 0.5 parts of nonionic emulsifiers of 1.7 parts of sodium dodecylbenzenesulfonate (DS-4AP) anionic emulsifier and octylphenol polyoxyethylene ether (X-305);

[0049] The emulsifier for the continuous reaction is specifically 0.8 parts of reactive anionic emulsifier of sodium allyl sulfonate (SAS) and 1.6 parts of anionic emulsifier of ethoxylated ether ammonium sulfate EP-120;), 60 parts of deionized Water, 0.5 part of ammonium persulfate, 0.3 part of sodium bisulfite, 0.2 part of sodium bicarbonate, 0.04 part of zinc formaldehyde sulfoxylate, 90 parts of vinyl acetate monomer, 25 parts of ethylene, prepare the fine particle size with the method of embodiment 1 VAE emulsion, the results are as follows:

[0...

Embodiment 3

[0052] Get 7 parts of emulsifiers (3.8 parts of emulsifiers for initial stage reaction, 3.2 parts of emulsifiers for continuous reaction; wherein said emulsifier for initial stage reaction is specifically allyloxy nonylphenol polyoxyethylene (10) ether ammonium sulfate ( DNS-86) reactive anionic emulsifier 0.8 parts, sodium dodecylbenzenesulfonate (DS-4AP) anionic emulsifier 2.4 parts and octylphenol polyoxyethylene ether (CA-630) nonionic emulsifier 0.6 Part; The emulsifier for the continuous reaction is specifically 0.8 parts of reactive anionic emulsifier of sodium allyl sulfonate (SAS) and 2.4 parts of anionic emulsifier of ethoxylated ether ammonium sulfate EP-110;), 80 parts Deionized water, 0.3 part of ammonium persulfate, 0.2 part of sodium bisulfite, 0.1 part of sodium bicarbonate, 0.03 part of zinc formaldehyde sulfoxylate, 100 parts of vinyl acetate monomer, 20 parts of ethylene, prepare fine Particle size VAE emulsion, the results are as follows:

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com