Preparation method of water-soluble composite InP/ZnS luminescent quantum dots for fingerprint appearance

A water-soluble composite and quantum dot technology, applied in chemical instruments and methods, diagnostic records/measurements, applications, etc., to achieve the effects of mild conditions, low synthesis temperature, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

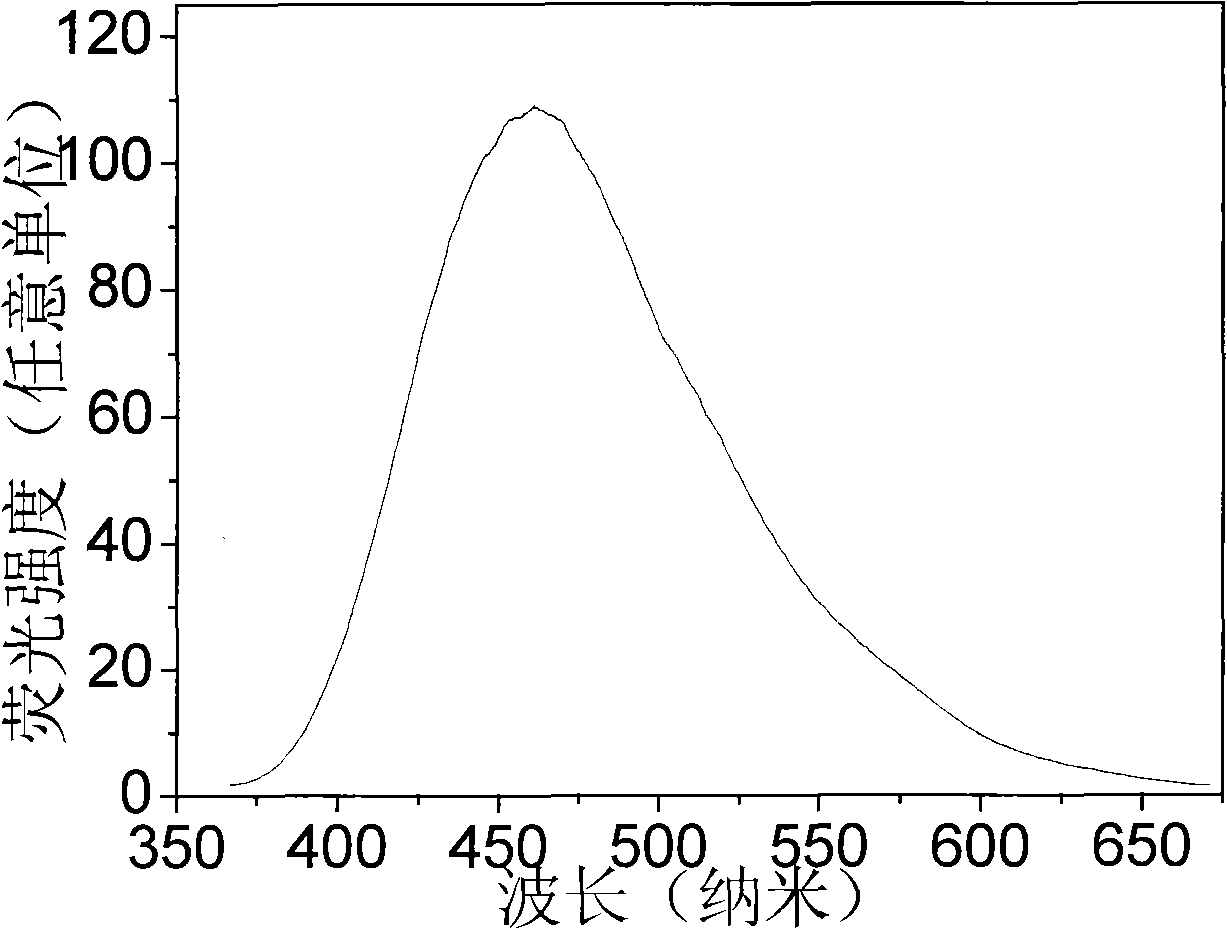

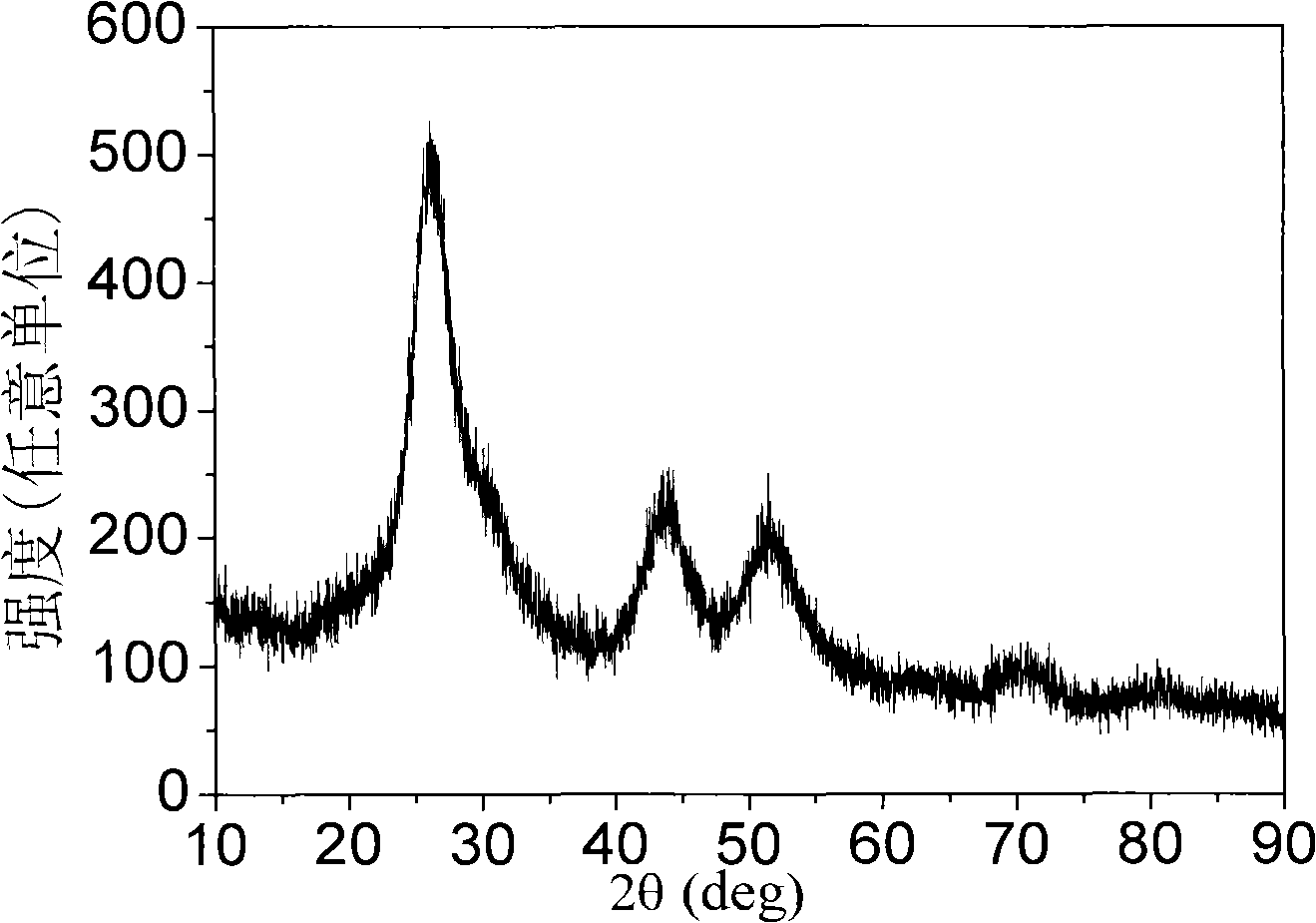

[0019] (1). Synthesis of water-soluble InP / ZnS: the synthesis temperature of InP is 150°C, TGA / Zn 2+ =2.4, the phase inversion temperature is 40°C.

[0020] Synthesis of InP in the organic phase: In an inert gas glove box, 0.4gInCl 3 , 0.45gP(N(CH 3 ) 2 ) 3 , 5g of surfactant dodecylamine (DDA) etc. are dissolved in a 50ml reaction kettle with 5ml of toluene, after sealing, take it out from the glove box, place it in a 70°C oven and heat it for 1h to dissolve the raw materials, and then heat to The reaction was carried out at 150°C and kept for 24 hours. After the reaction was completed, it was cooled to room temperature, and the upper layer solution was removed and washed with methanol several times. The product was dried in a vacuum oven at 60°C for 12 hours to obtain InP solid powder.

[0021] (2).InP quantum dots are transferred to the water phase: take 0.58g Zn(Ac) 2 2H 2 O and 0.59 g of thioglycolic acid (TGA) were added to 20 ml of deionized water, that is, Zn 2+...

Embodiment 2

[0025] Change synthesis temperature, change TGA / Zn 2+ Proportioning, the specific steps are as follows:

[0026] (1). Synthesis of water-soluble InP / ZnS: the synthesis temperature of InP is 165°C, TGA / Zn 2+ =1.9, the phase inversion temperature is 40°C.

[0027] Synthesis of InP in the organic phase: In an inert gas glove box, 0.4gInCl 3 , 0.45gP(N(CH 3 ) 2 ) 3 , 5g of surfactant dodecylamine (DDA) etc. are dissolved in a 50ml reaction kettle with 5ml of toluene, after sealing, take it out from the glove box, place it in a 70°C oven and heat it for 1h to dissolve the raw materials, and then heat to The reaction was carried out at 165°C and kept for 24 hours. After the reaction was completed, it was cooled to room temperature, the upper layer solution was opened and washed with methanol several times, and the product was dried in a vacuum oven at 60°C for 12 hours to obtain InP solid powder.

[0028] (2). Take 0.58g Zn(Ac) 2 2H 2 O and 0.47gTGA were added to 20ml deioni...

Embodiment 3

[0032] Change synthesis temperature, change phase inversion temperature, concrete steps are as follows:

[0033] (1). Synthesis of water-soluble InP / ZnS: the synthesis temperature of InP is 180°C, TGA / Zn 2+ =2.4, the phase inversion temperature is 50°C.

[0034] Change the reaction synthesis temperature to 180° C., and the operation of synthesizing InP in other specific organic phases is the same as that in Example 1 (1), to obtain InP solid powder.

[0035] (2). Take 0.58g Zn(Ac) 2 2H 2 O and 0.59g TGA were added to 20ml deionized water, that is, Zn 2+ The molar concentration is 0.13mol / L, and the molar ratio is TGA / Zn 2+ =2.4 solution. Take 0.006g of the InP powder prepared by (1) in 10ml of the mixed solution of hexane and butanol (the volume ratio of hexane and butanol is 2:1) and ultrasonically disperse for 2min, add 10ml of the ZT solution prepared above, at 50℃ Stirring was continued at temperature for 1 h. Concrete operation is with embodiment 1 (2).

[0036] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com