Fruit anti-cracking nutritional agent and preparation method thereof

A nutrient agent and anti-cracking technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of difficulty in wide-scale promotion of variety improvement, high cost of rain-shelter cultivation, and difficulty in realization, and achieves the promotion of fruit cortex growth and non-toxicity. Side effects, the effect of improving cell viability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. take by weighing the sodium carboxymethyl cellulose of 10 weight parts, be dissolved in the water of 15 weight parts, obtain the sodium carboxymethyl cellulose aqueous solution;

[0044] 2. Add 5 parts by weight of amino acid chelated calcium to the sodium carboxymethylcellulose aqueous solution described in step 1., and heat to 40-50° C.;

[0045] ③Then add 3 parts by weight of ethylene glycol to the solution in step ②, stir at 40-50°C for 30-40min, and then place it at room temperature.

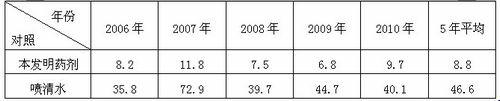

[0046] The control effect of this embodiment on fruit cracking was tested on jujube trees. See comparative test 3.

[0047] The function of each ingredient is explained as follows:

[0048] Amino acid chelated calcium: Amino acid chelated calcium is a new type of organic calcium supplement, which can be directly absorbed by plants after spraying. Calcium is an important structural component in the cell wall. It combines with pectin to form calcium pectate, which increases the T...

Embodiment 2- Embodiment 3

[0055] The preparation method is the same as that of Example 1, and the parts by weight of each component are shown in Table 4.

[0056] Table 4 The weight ratio of each component in embodiment 2-3 and embodiment 5-7

[0057] components

Example 2

Example 3

Example 5

Example 6

Example 7

Sodium carboxymethyl cellulose

15

5

5

13

15

3

7

3

4

5

Ethylene glycol

5

1

2

5

5

-

-

0.01

0.9

0.3

water

15

10

10

20

15

[0058] Note: ① The calcium agent is replaced by amino acid chelated calcium, calcium chloride or calcium nitrate;

[0059] ②The plant growth regulator is brassinolide or naphthaleneacetic acid.

Embodiment 4

[0061] 1. take by weighing the sodium carboxymethyl cellulose of 10 weight parts, be dissolved in the water of 15 weight parts, obtain the sodium carboxymethyl cellulose aqueous solution;

[0062] 2. Add 5 parts by weight of amino acid chelated calcium to the sodium carboxymethylcellulose aqueous solution described in step 1., and heat to 40-50° C.;

[0063] ③Then add 3 parts by weight of ethylene glycol to the solution in step ②, stir at 40-50°C for 30-40min, and then place it at room temperature;

[0064] ④ Add 0.5 parts by weight of brassinolide to the solution in step ③ and stir evenly to obtain the anti-cracking nutrient for fruit.

[0065] During the test, it was found that the agent made of sodium carboxymethylcellulose, ethylene glycol and amino acid chelated calcium was applied in large-scale production. Although the anti-cracking effect was very good, it was affected by the protective film formed after spraying. , the rate of absorption of calcium ions by the fruit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com