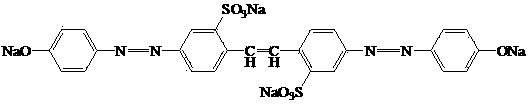

Method for preparing direct yellow G

A frozen yellow and direct technology, applied in etherification preparation and other directions, can solve the problems of lack of competitiveness, difficult governance, increased production costs, etc., and achieve the effect of reducing production costs, large market competitiveness, and achieving zero emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

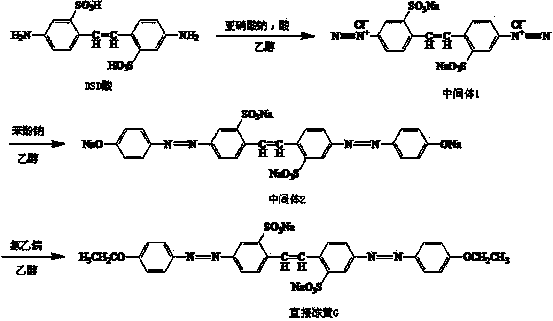

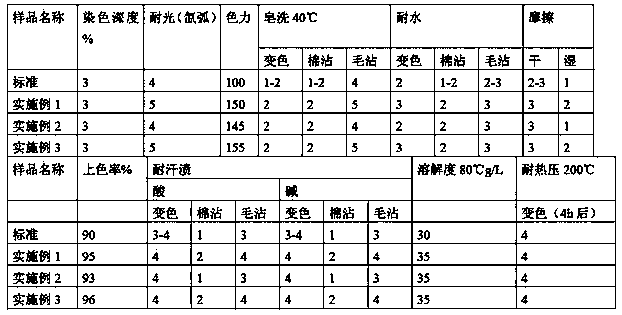

Embodiment 1

[0030] The preparation method of the direct frozen yellow G of the present embodiment, the steps are as follows:

[0031] 1) Add 2400L of ethanol, 400kg of DSD acid, and 500kg of hydrochloric acid to the diazo reaction tank at one time to maintain the acidic environment of the diazo reaction, stir and beat for 2 hours, control the temperature at 20°C, and add dropwise a solution containing 152kg of sodium nitrite Alcohol solution can also be used, the purpose is to allow sodium nitrite to be better mixed with the beating liquid, the present embodiment adopts 190kg of water and 165kg of ethanol to prepare the above-mentioned sodium nitrite solution, and the total time of dropping is 40 minutes , control the temperature at 20°C and continue the reaction for 0.5 hours. During the diazotization process, the appearance of the solution will change from light yellow to yellow-brown, and the material will also change from thick to thin; at the end of the reaction, there is a slight exc...

Embodiment 2

[0037] The preparation method of the direct frozen yellow G of the present embodiment, the steps are as follows:

[0038] 1) Add 3000L of ethanol, 400kg of DSD acid, and 500kg of hydrochloric acid to the diazo reaction tank at one time to maintain the acidic environment of the diazo reaction, stir and beat for 2 hours, control the temperature at 25°C, and add dropwise a solution containing 152kg of sodium nitrite Alcohol solution can also be used, and the purpose is to allow sodium nitrite to be better mixed with the beating liquid. In this embodiment, 190kg of water and 165kg of ethanol are used to prepare the above-mentioned sodium nitrite solution, and the total time for dropping is 50 minutes. , control the temperature at 25°C and continue the reaction for 0.8 hours. During the diazotization process, the appearance of the solution will change from light yellow to yellowish brown. Destroy excess sodium nitrite to obtain a diazonium salt solution containing intermediate 1 of...

Embodiment 3

[0044] The preparation method of the direct frozen yellow G of the present embodiment, the steps are as follows:

[0045]1) Add 3600L of ethanol, 400kg of DSD acid, and 500kg of hydrochloric acid to the diazo reaction tank at one time to maintain the acidic environment of the diazo reaction, stir and beat for 2 hours, control the temperature at 30°C, and add dropwise a solution containing 152kg of sodium nitrite Alcohol solution can also be used, the purpose is to allow sodium nitrite to better mix evenly with the beating liquid, the present embodiment adopts 190kg of water and 165kg of ethanol to prepare the above-mentioned sodium nitrite solution, and the total time of dropping is 60 minutes , control the temperature at 30°C and continue the reaction for 1 hour. During the diazotization process, the appearance of the solution will change from light yellow to yellow-brown. Destroy excess sodium nitrite to obtain a diazonium salt solution containing intermediate 1 of formula 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com