Method for preparing liquid fuel from coal petrography oil-gas reservoir

A liquid fuel, oil and gas reservoir technology, applied in the petroleum industry, hydrogen production, processing of hydrocarbon oil, etc., can solve the problems of unsatisfactory reaction effect, lack of treatment methods for residues, etc., to achieve low investment cost and operating cost, improve Value, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

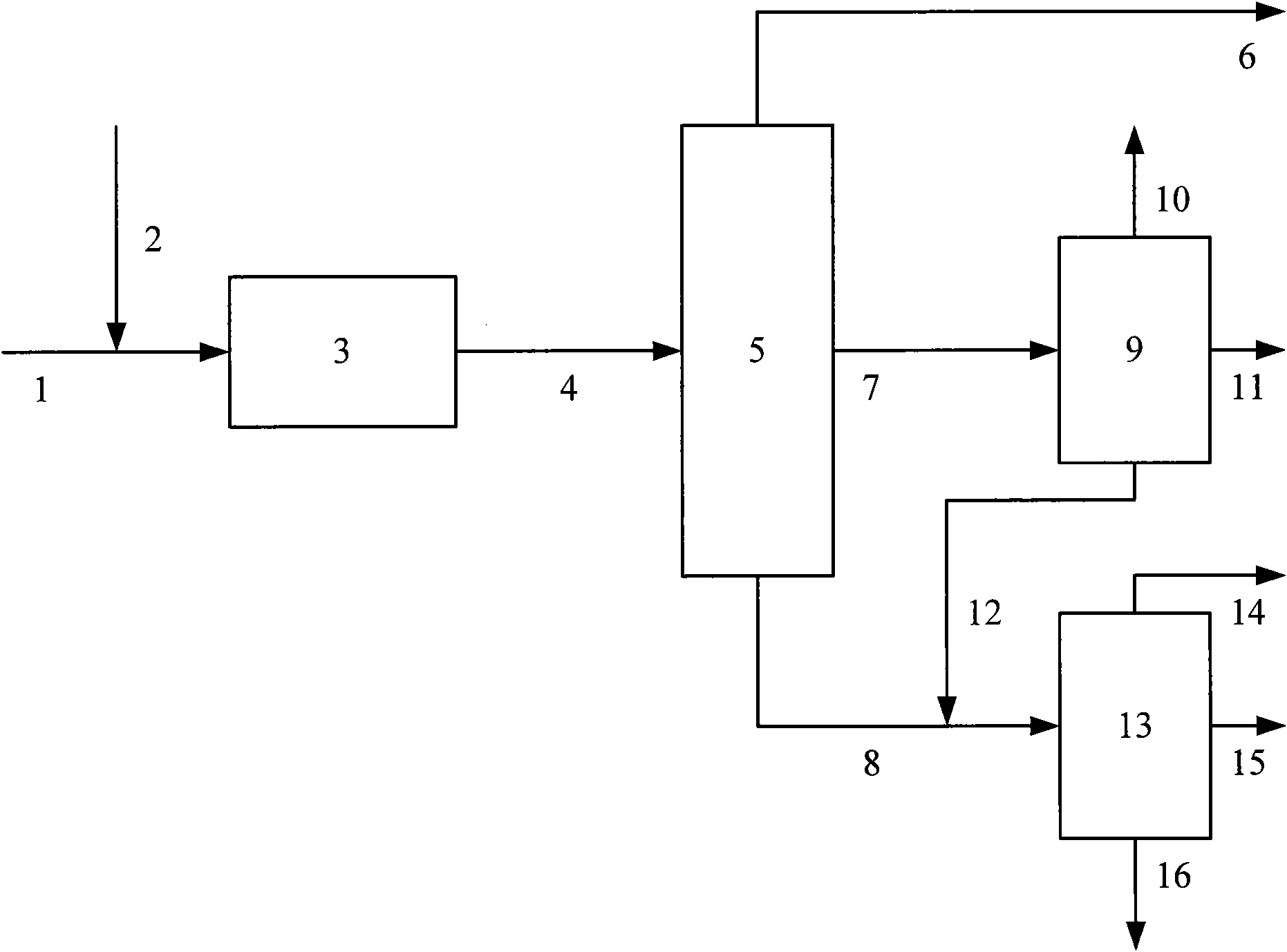

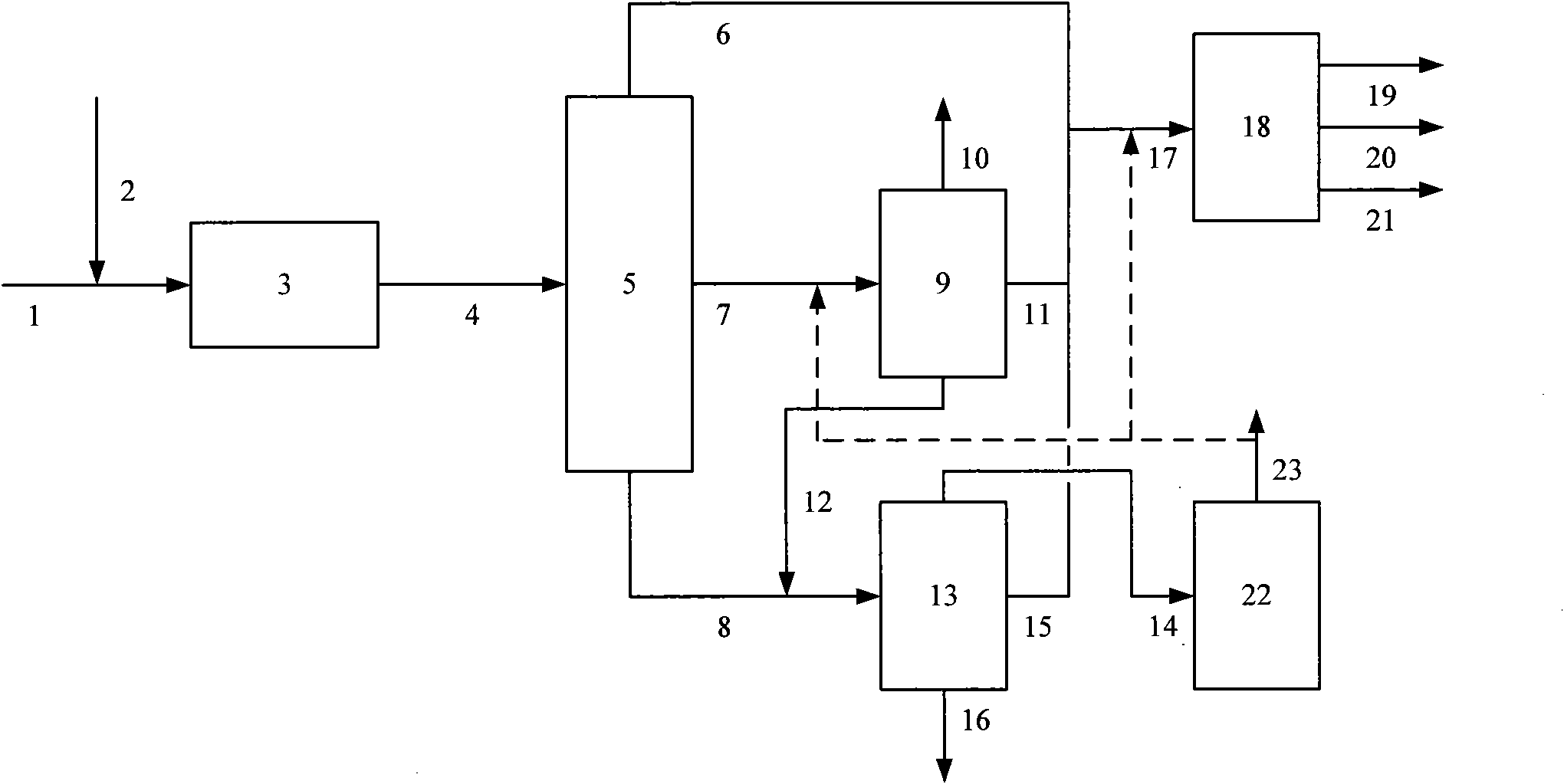

Method used

Image

Examples

example 1

[0047] Example 1 hot melting and dispersion

[0048] Take 1kg of natural heavy crude oil from Shengli Oilfield (density at 20°C is 950kg / m 3 , H / C molar ratio is 1.61), and 0.6kg Shandong Huangxian lignite. Crush coal into coal powder, 100-200 mesh. Huangxian coal was formed in the third Shahejie Formation of the Tertiary system, which is the same as the natural heavy crude oil in Shengli Oilfield, and is also the third Shahejie Formation of the Tertiary system, and its properties are shown in Table 1.

[0049] Table 1. Industrial analysis and elemental data of lignite in Huangxian, Shandong

[0050] Industrial Analysis

Moisture M ad , wt% 9.55

C, weight% 77.39

Ash A d , wt% 11.86

H, wt% 5.53

Volatile V daf , wt% 45.11

N, weight% 2.14

S, weight% 0.77

O, wt% 14.17

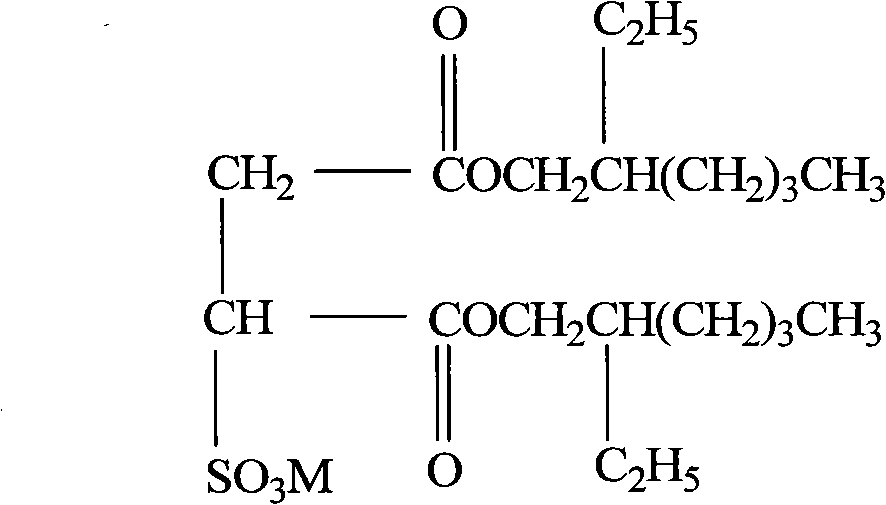

[0051] After mixing and stirring, age for 24 hours, add 0.5% by weight of co-solvent 1,4-bis(2-ethylhexyl) sodiu...

example 2

[0054] The hydrocracking of example 2 sol phase

[0055] Use JQ-100 heavy oil hydrogenation high-pressure micro-reactor device. The hydrocracking catalyst used is iron chromium lignosulfonic acid (FeCr-LS), and the hydrocracking catalyst accounts for 1.5% by weight of the sol phase. M in sol phase ad ≤0.1 wt%, A ad ≤0.2% by weight, H / C=1.52 (molar ratio), O / C=0.048, density (20°C)=1050kg / m 3 . The reactant outlet temperature is 430°C, and the initial hydrogen partial pressure is 5.6MPa. As a result, the density of hydrogenated distillate oil (20°C) = 900kg / m 3 , H / C increased to 1.78, its A ad ≤0.05%. H / C of hydrogenated residual oil=1.28 (molar ratio).

example 3

[0056] Coking reaction of example 3 gel phase and hydrogenated residual oil

[0057] The coking tests were carried out on a delayed coking medium-sized unit. The oil-coal slurry enters the heating furnace, and after being heated to 490°C, it enters the coke tower for coking reaction. The coke generated by the reaction is deposited in the coke tower, and the coked oil gas enters the fractionating tower to fractionate into coking gas and coking oil. The operating conditions and material balance are listed in Table 3, the distillation range of coker oil is listed in Table 4, and the properties of coke are listed in Table 5.

[0058] Table 3 coking operating conditions and material balance

[0059] Coking operating conditions

temperature, ℃

490

Pressure (gauge pressure), MPa

0

Coking material balance

Coking gas, wt%

7.5

Coker oil, weight %

37.5

Coke, wt%

51.3

water, wt%

3.7

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com