Anthracene oil hydrogenation method

A technology for hydrocracking of anthracene oil, which is applied in the field of hydrogenation of anthracene oil to produce light fuel oil, can solve the problems of limiting the application of anthracene oil hydrocracking technology, high requirements for hydrocracking catalysts, and affecting the service life of catalysts, etc., reaching The effect of safe and stable operation, saving equipment investment and increasing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0038] The properties of the anthracene oil raw materials used are shown in Table 1.

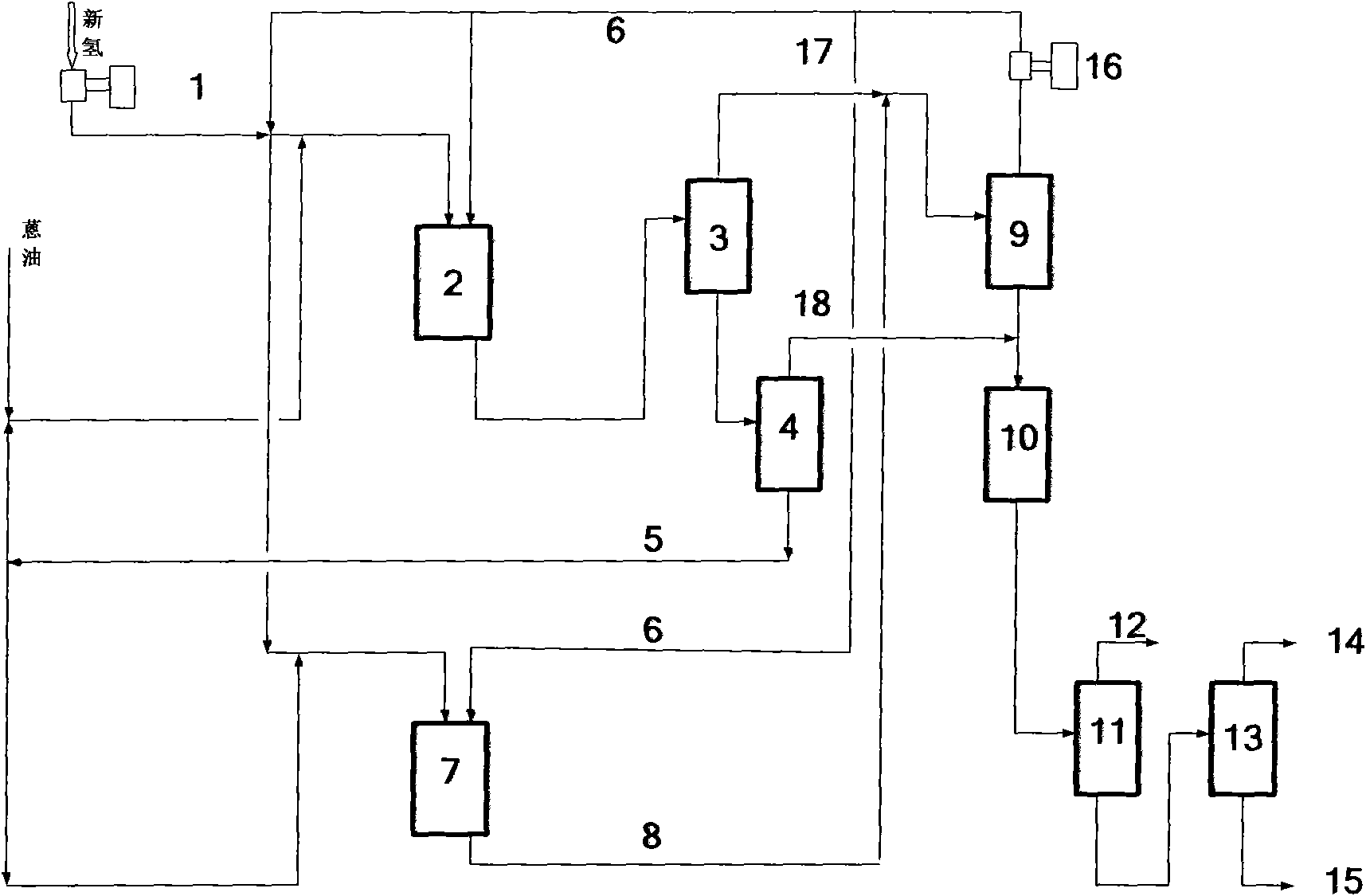

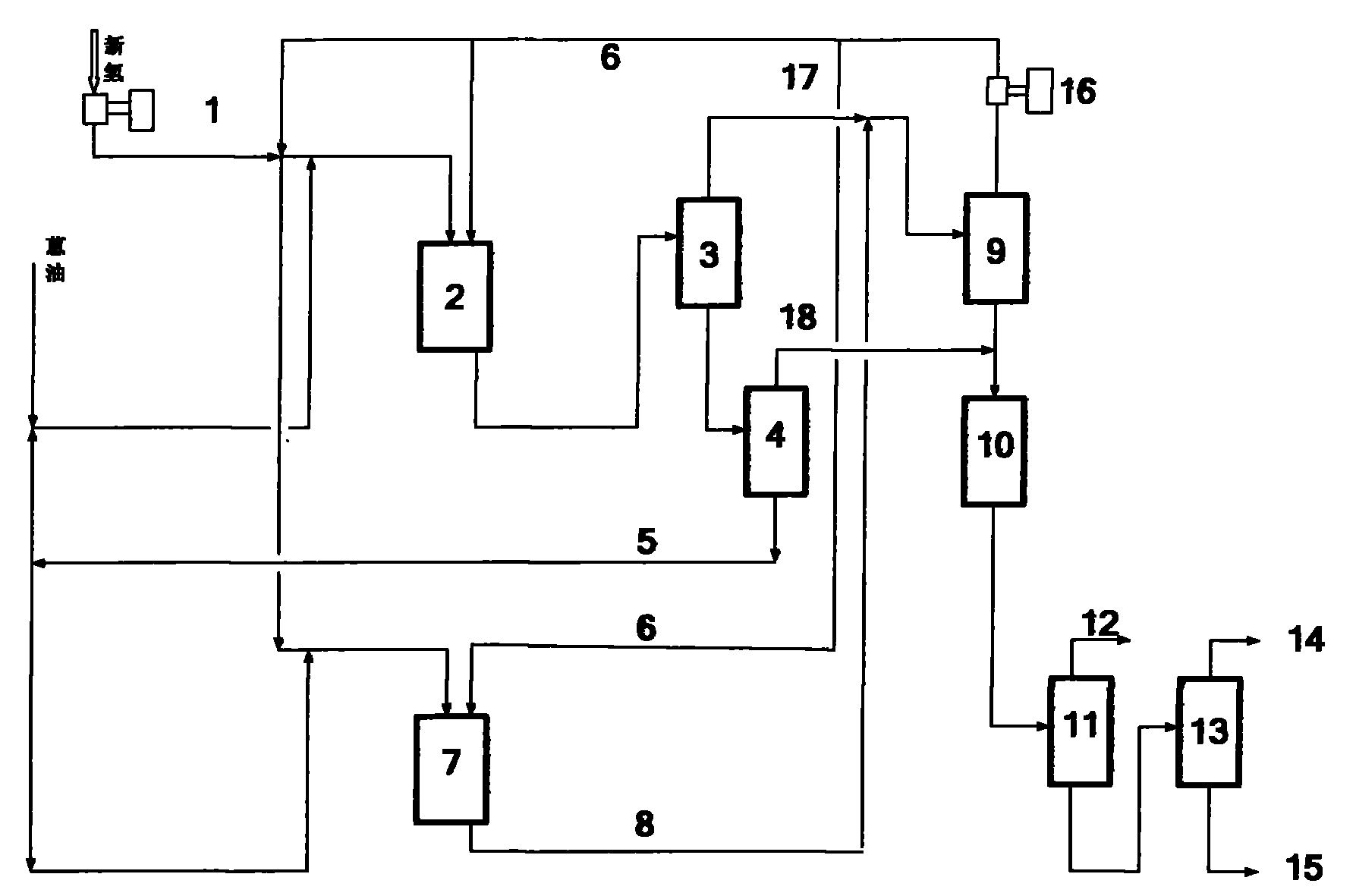

[0039] A two-stage hydrocracking process is adopted, and the specific operation process is shown in figure 1 .

[0040] Preparation of hydrocracking catalysts containing amorphous silica-alumina and Y zeolite: A1, A2.

[0041] Hydrocracking catalyst A1:

[0042] Amorphous silicon aluminum (specific surface 520m 2 / g, SiO 2 35wt%, pore volume 1.2ml / g) and Y molecular sieve (SiO 2 / Al 2 o 3 9, unit cell constant 2.432, specific surface 650m 2 / g, infrared acidity 0.45mmol / g), after mixing, add the adhesive (prepared by peptizing small-pore alumina with a pore volume of 0.42ml / g and dilute nitric acid) and roll it into a ball, then put it into the extruder After extruding, dry at 110°C for 10 hours, activate at 500°C for 4 hours to prepare the carrier, then impregnate with Mo-Ni co-impregnation solution, then dry at 110°C for 12 hours, and activate at 500°C for 3 hours. The final comp...

Embodiment 1

[0050] Examples 1-3 The liquid phase product obtained after the hydrofinishing oil passes through the separation system is recycled back to the hydrofinishing reaction zone and mixed with anthracene oil. The circulation weight ratio of Examples 1 and 2 is 3.0, and the circulation of Example 3 The weight ratio is 5.0.

[0051] Table 1 Raw Oil Properties

[0052] crude oil name

[0053] Table 2 Hydrogenation process conditions and properties of diesel fraction products

[0054] Program

[0055] Nitrogen content / μg·g -1

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com