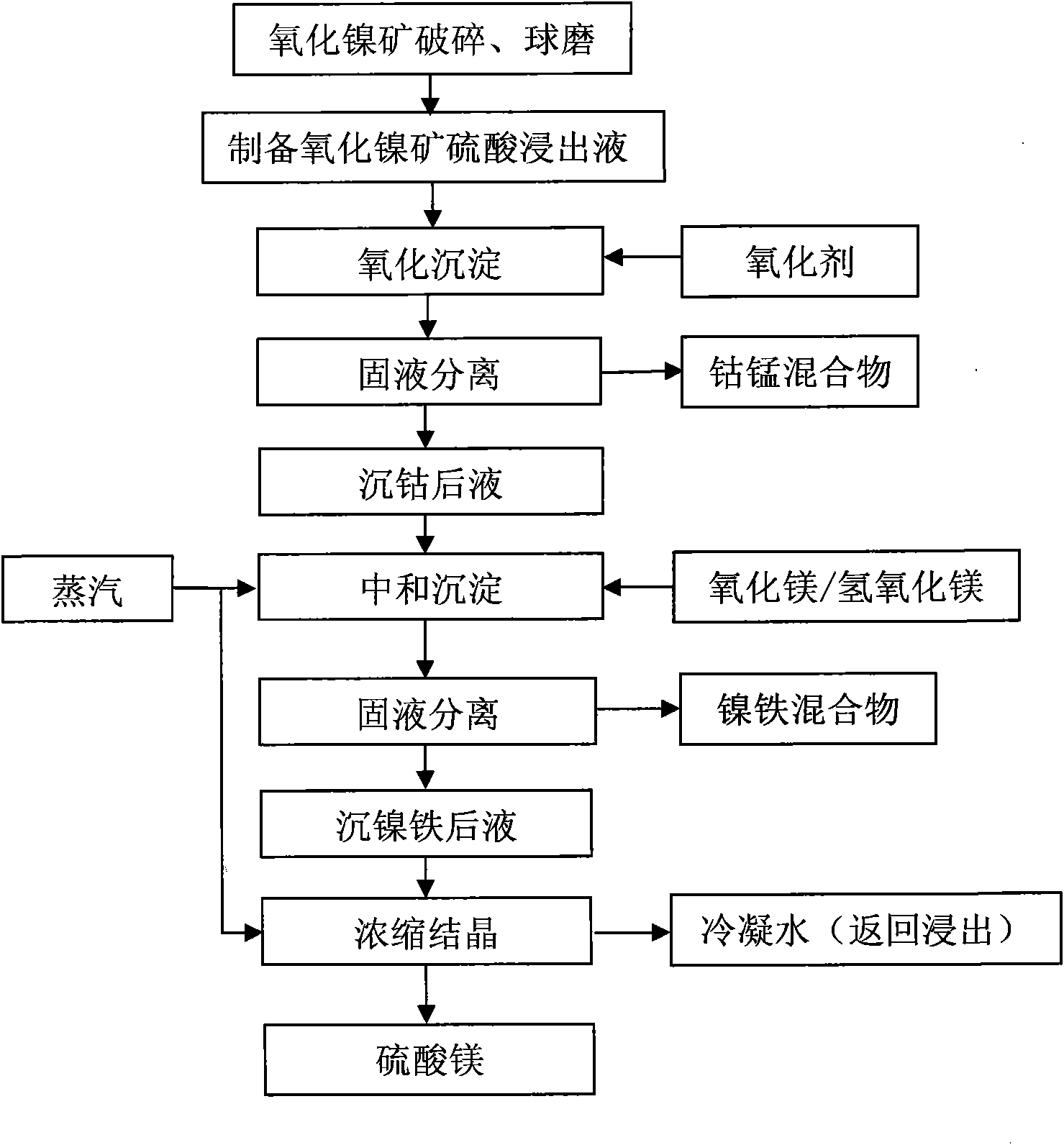

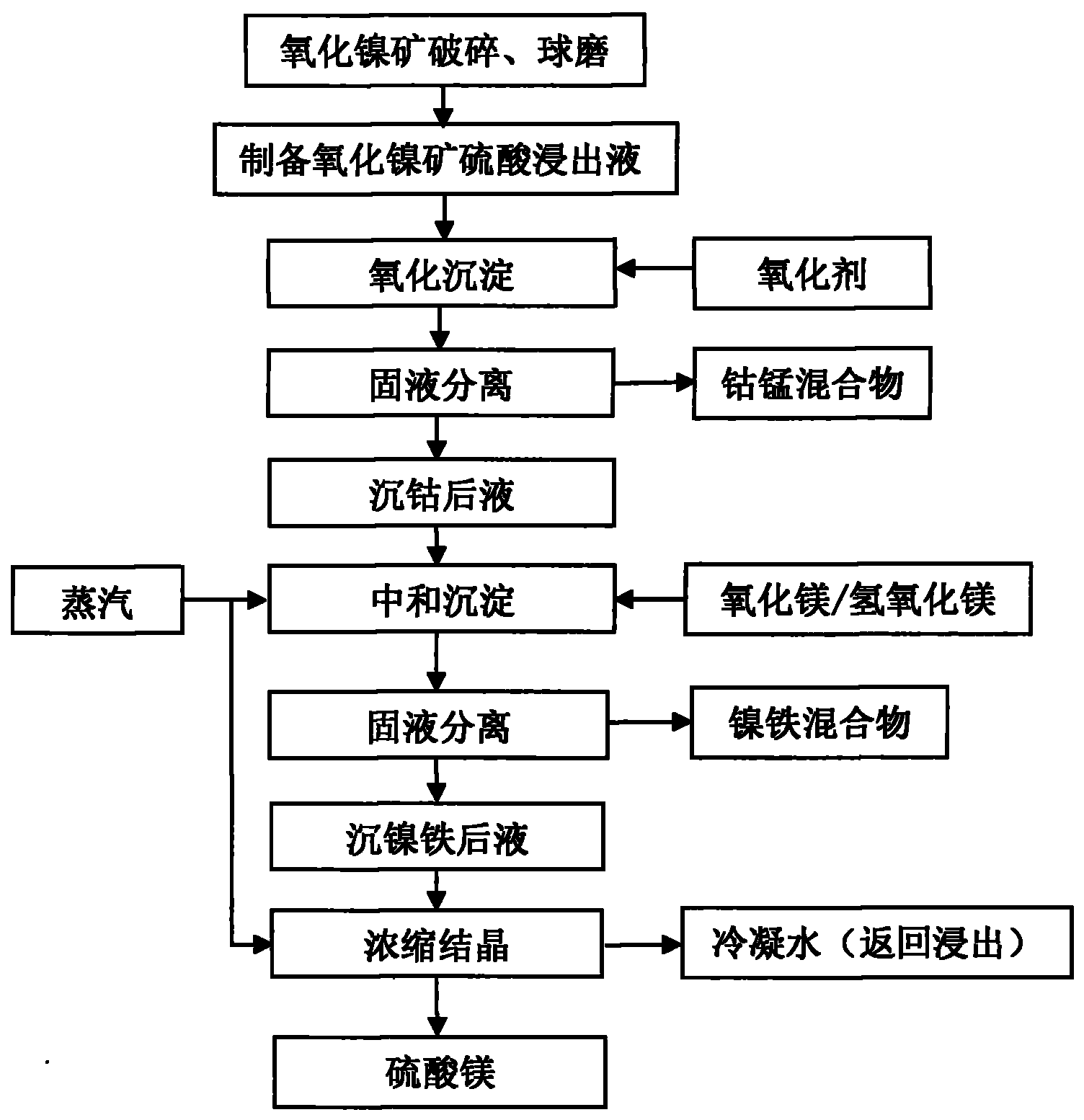

Method for recovering nickel, cobalt, iron, manganese and magnesium from oxidized nickel ore

A technology of nickel oxide ore and nickel-cobalt-iron, which is applied in the field of hydrometallurgy, can solve the problems of nickel and cobalt loss, and achieve environmental friendliness, economic benefits and strong environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The composition of nickel oxide ore used (% by weight): Ni 1.4, Fe 14, Co 0.08, MgO18.5, SiO 2 35.7, Mn 1.2, CaO0.3, Al 2 o 3 6.08, Cr1.02.

[0034] Leaching conditions: material particle size -74μm accounted for 70%, sulfuric acid dosage 1.2 times the theoretical amount, leaching temperature 85°C, leaching time 60min, liquid-solid ratio 3:1, stirring linear speed 4.5m / s. Leaching rate: nickel 96%, cobalt 94%, magnesium 95%, iron 55%, manganese 75%.

[0035] The content of main elements in sulfuric acid leaching solution of nickel oxide ore is as follows (g / L): Fe 25, Ni 4.5, Co 0.25, Mg 35, Mn 3, Al 1.5, pH=1.

[0036] Cobalt-manganese oxidation co-precipitation process conditions: add sodium chlorate twice the theoretical amount of cobalt and manganese for oxidation precipitation, oxidation precipitation temperature 60 ° C, oxidation precipitation time 60 minutes. Precipitation rate: cobalt 82%, manganese 96%. The weight percent content of the obtained cobalt-man...

Embodiment 2

[0040] The composition of nickel oxide ore used (% by weight): Ni 1.6, Fe 16Co 0.07, MgO15.8, SiO 241.2, Mn1.1, CaO0.2, Al 2 o 3 5.28, Cr0.92.

[0041] Leaching conditions: material particle size -74μm accounted for 70%, sulfuric acid dosage 1.25 times the theoretical amount, leaching temperature 88°C, leaching time 60min, liquid-solid ratio 3:1, stirring linear speed 5m / s. Leaching rate: nickel 98%, cobalt 96%, magnesium 94%, iron 54%.

[0042] The content of main elements in sulfuric acid leaching solution of nickel oxide ore is as follows (g / L): Fe 28, Ni 5.2, Co 0.22, Mg 30, Mn 2.93, Al 1, pH=0.5.

[0043] Cobalt-manganese oxidation co-precipitation process conditions: add ammonium persulfate three times the theoretical amount of cobalt and manganese for oxidation precipitation, oxidation precipitation temperature 50 ° C, oxidation precipitation time 90 minutes. Precipitation rate: cobalt 88%, manganese 98%. The weight percent content of the obtained cobalt-manganese ...

Embodiment 3

[0047] The composition of nickel oxide ore used (% by weight): Ni 1.8, Fe 13, Co 0.08, MgO16.5, SiO 2 38.2, Mn1.8, CaO0.32, Al 2 o 3 4.57, Cr1.15.

[0048] Leaching conditions: material particle size -74μm accounted for 60%, sulfuric acid dosage 1.25 times the theoretical amount, leaching temperature 90°C, leaching time 60min, liquid-solid ratio 3:1, stirring linear speed 5m / s. Leaching rate: nickel 98.5%, cobalt 96.5%, magnesium 95.5%, iron 56%.

[0049] The content of main elements in sulfuric acid leaching solution of nickel oxide ore is as follows (g / L): Fe 24, Ni 5.9, Co 0.26, Mg 31.5, Mn 4, Al 1.2, pH=0.6.

[0050] Cobalt-manganese oxidation co-precipitation process conditions: add sodium hypochlorite three times the theoretical amount of cobalt and manganese for oxidation precipitation, oxidation precipitation temperature 40 ° C, oxidation precipitation time 60 minutes. Precipitation rate: cobalt 80%, manganese 92%. The weight percent content of the obtained cobalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com