Degradable nerve conduit with highly-oriented tube-in-tube structure and manufacturing method thereof

A nerve conduit and tube-in-tube technology, which is applied in the field of degradable nerve conduits and their preparation, can solve the problems of hindering the forward growth of regenerated nerve fibers, unable to reach the in-situ of regenerated tissue, and losing function, and achieves good biocompatibility. , promote regeneration and repair, improve the effect of fiber orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Dissolve PHBV and PLGA (50:50) in chloroform at a mass ratio of 2:1 to prepare a polymer solution with a mass fraction of 6%; stir until clear without turbidity, and add NaCl with a particle size of 300 μm As a porogen, the mass fraction of NaCl is 10%; after mixing evenly, the polymer solution is cast into a cylindrical mold with a 4-channel inner diameter of 3mm to obtain an outer tubular substrate, and the casting process is repeated several times; Remove the mold after vacuuming, rinse the tubular substrate repeatedly with deionized water after the solvent is completely evaporated to remove the porogen, and finally vacuum dry to a constant temperature to obtain a high-porosity outer tubular substrate. The outer tubular substrate is 3 mm in diameter and has 4 channels.

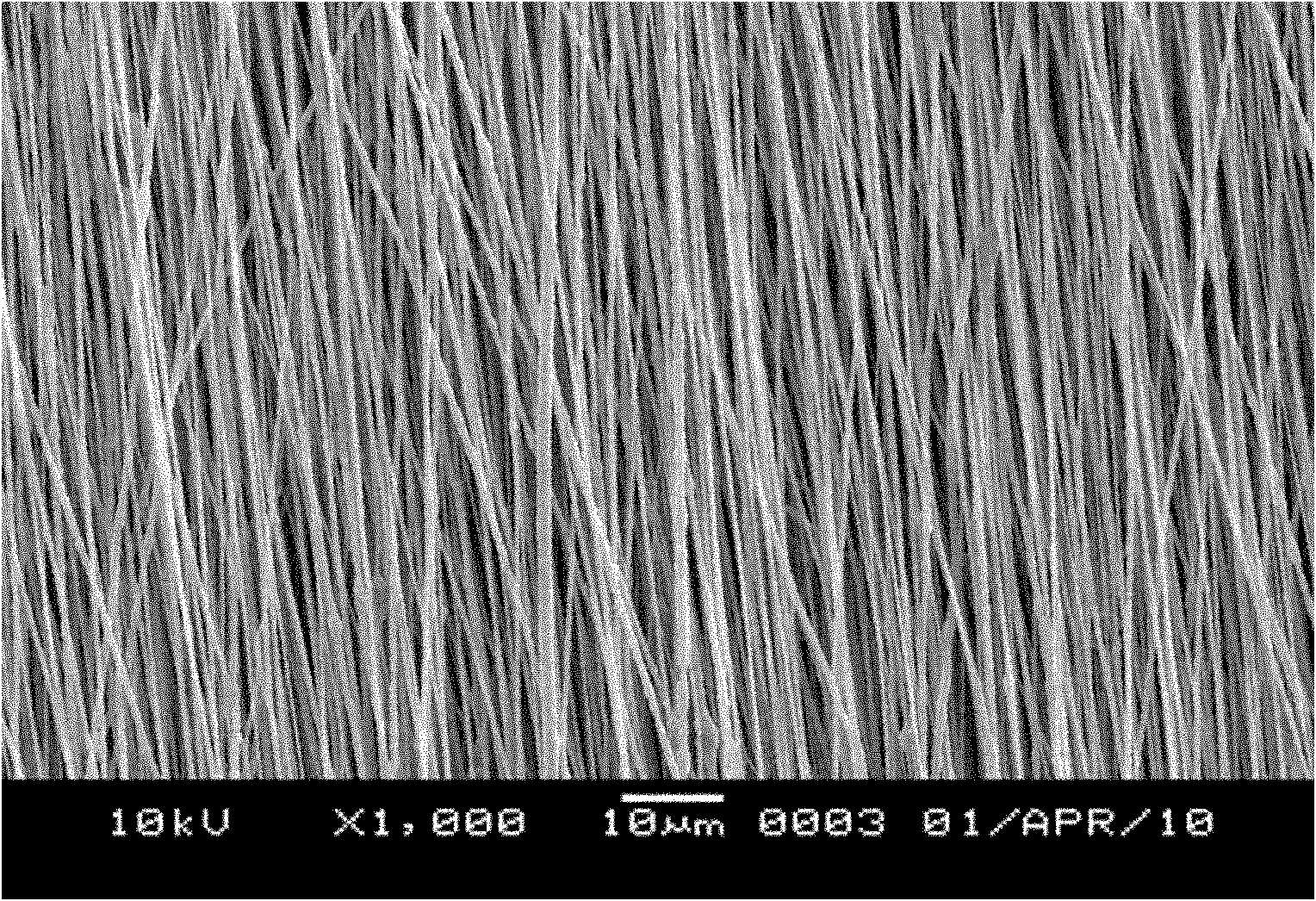

[0036] (2) PHBV and chitosan are dissolved in trifluoroacetic acid with a mass ratio of 50:50, and a 5% polymer solution is prepared, and magnetically stirred until clear without turbidity; Elec...

Embodiment 2

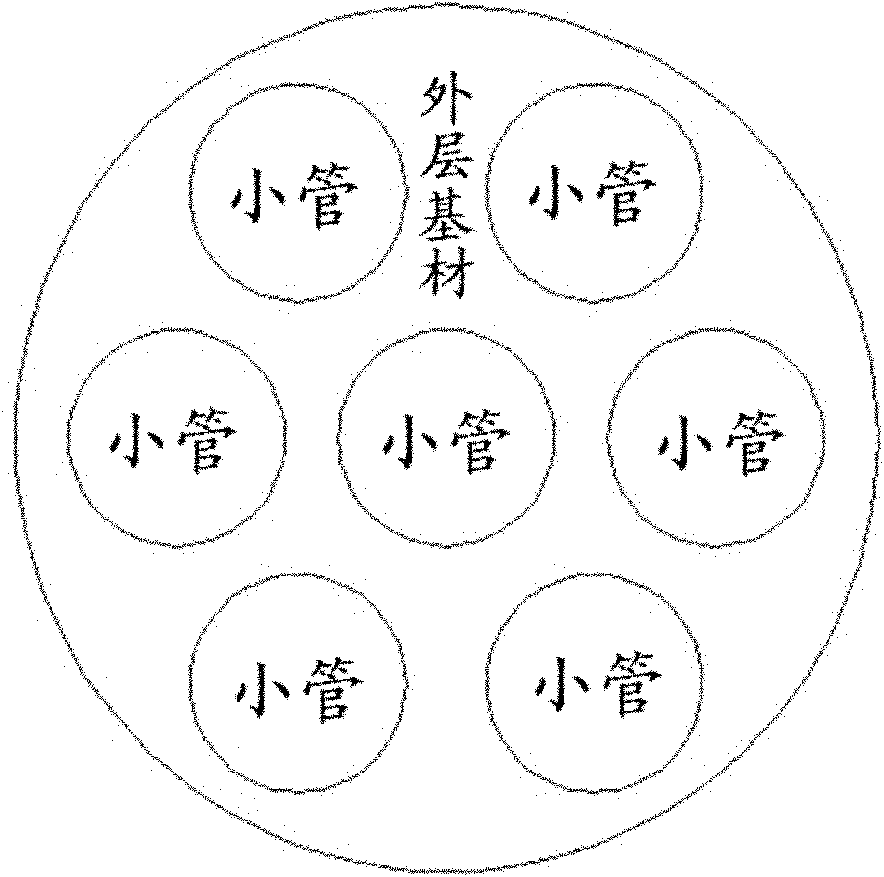

[0039] (1) Dissolve PHBV and PCL in chloroform with a mass ratio of 2:1 to prepare a polymer solution with a mass fraction of 8%; stir until it is clear without turbidity, and add NH with a particle size of 300 μm 4 HCO 3 porogen, NH 4 HCO 3 The mass fraction is 10%; the polymer solution is cast into the inner diameter of 4mm after mixing evenly, and the outer tubular substrate is prepared in a cylindrical mold with 7 channels, and the casting process is repeated several times; the mold is removed after vacuuming, and the After the solvent is completely evaporated, it is first washed several times with acid, and then the tubular substrate is repeatedly rinsed with deionized water to remove the porogen, and finally vacuum-dried to a constant temperature to obtain a high-porosity outer tubular substrate. The outer tubular substrate is 4mm in diameter and has 7 channels.

[0040] (2) PHBV and collagen were dissolved in hexafluoroisopropanol at a mass ratio of 75:25, and a 10% ...

Embodiment 3

[0043] (1) Dissolve PCL and PLGA (50:50) in chloroform at a mass ratio of 1:1 to prepare a polymer solution with a mass fraction of 8%; stir until it is clear without turbidity, and add NH with a particle size of 300 μm 4 HCO 3 porogen, NH 4 HCO 3 The mass fraction is 10%; after mixing evenly, the polymer solution is cast into a cylindrical mold with a 6-channel inner diameter of 5mm to obtain an outer tubular substrate, and the casting process is repeated several times; the mold is removed after vacuuming, and the After the solvent is completely evaporated, it is first washed several times with acid, then repeatedly washed with deionized water to remove the porogen, and finally vacuum-dried to a constant temperature to obtain a high-porosity outer tubular substrate. The outer tubular substrate is 5 mm in diameter and has 6 channels.

[0044] (2) Dissolve PHBV and collagen in hexafluoroisopropanol at a mass ratio of 50:50, prepare a 12% polymer solution, and magnetically st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com