Method and device for concentration of biogas and standard emission of clear liquid

A concentrated liquid and biogas slurry technology, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of inability to meet the standard discharge of permeate, difficult ammonium nitrogen interception, Through the problems of high concentration of liquid ammonia nitrogen, the effects of long-distance transportation, effective nutrient improvement, and simple operation are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

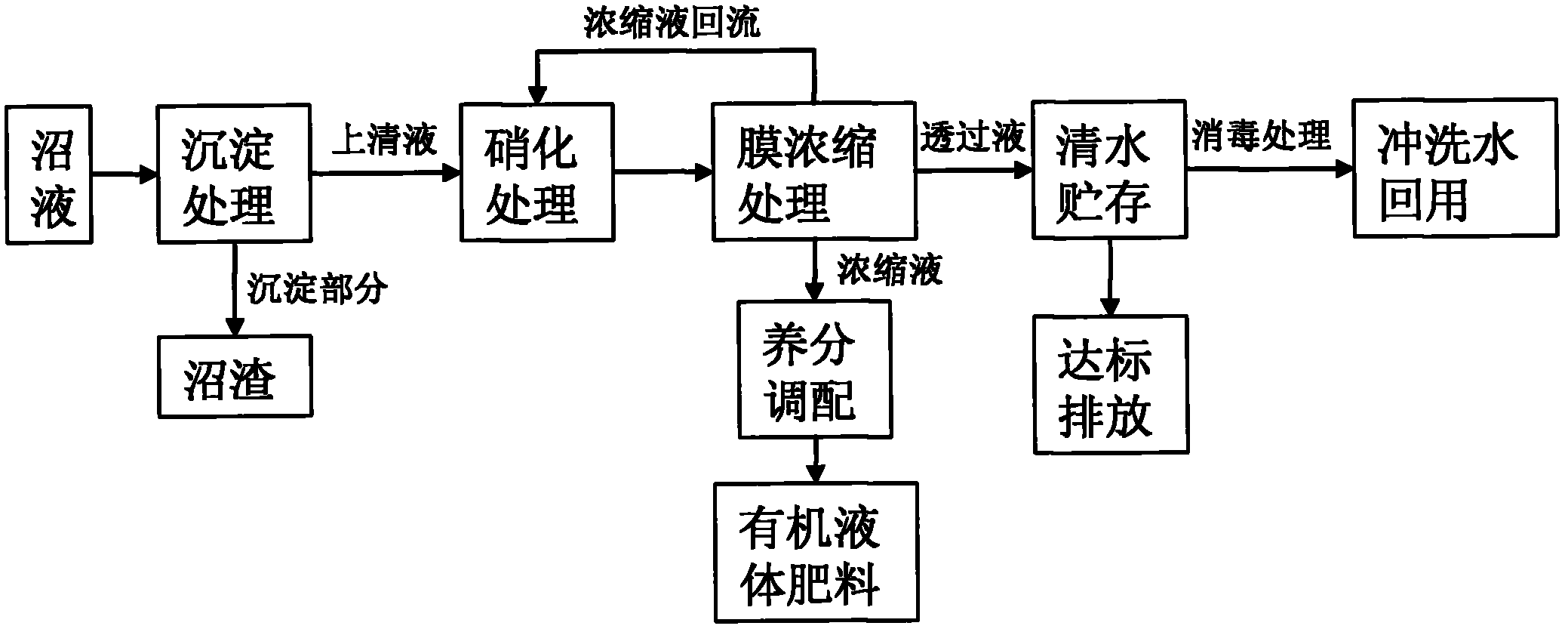

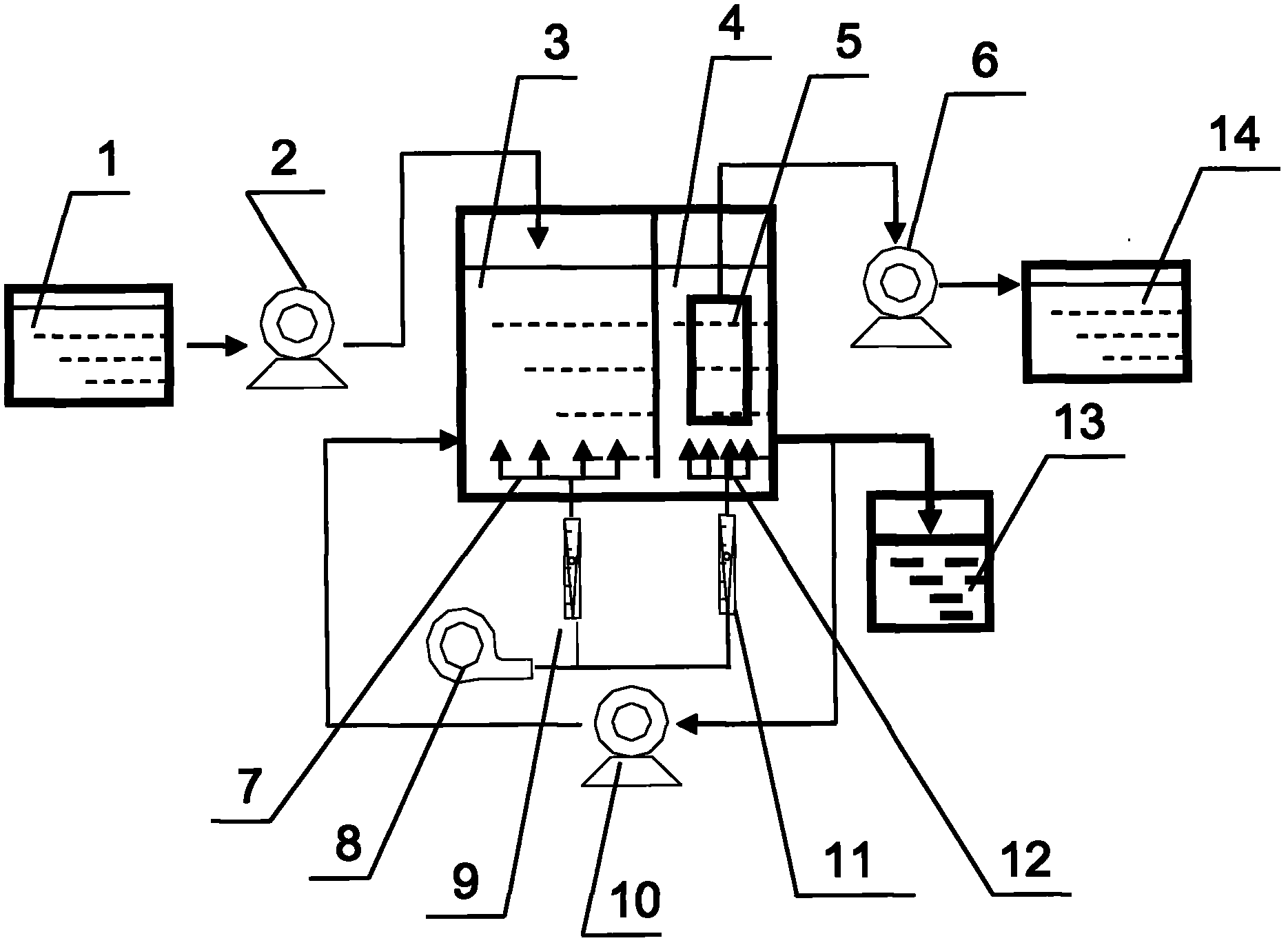

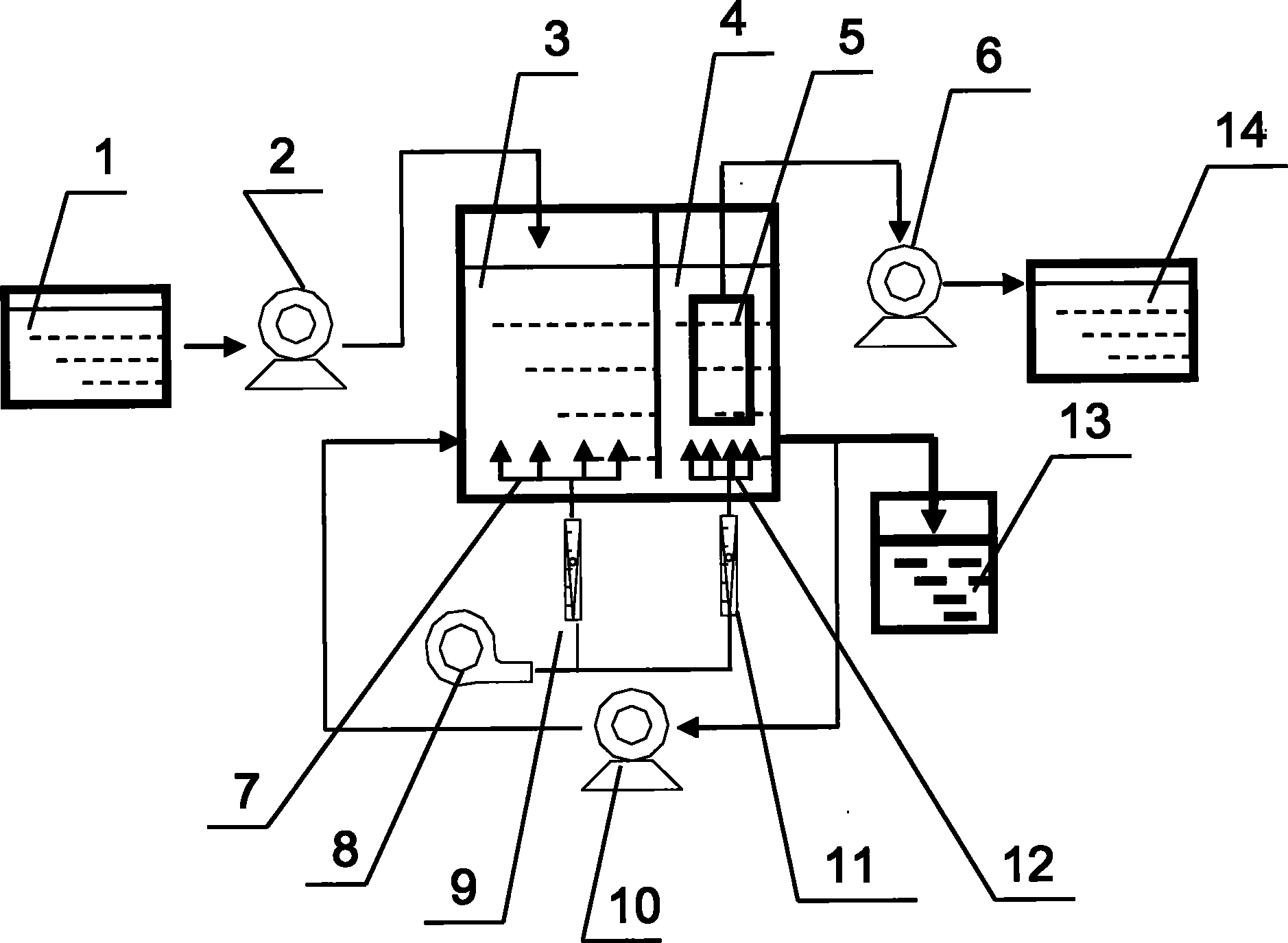

[0025] The invention discloses a method and equipment for concentrating biogas slurry and discharging the clear liquid up to the standard. The method is composed of six operation steps including precipitation, aerobic nitrification treatment, membrane filtration, nutrient allocation and disinfection, and is specifically carried out according to the following steps: (1) The biogas slurry discharged from the anaerobic reactor is first subjected to sedimentation treatment, so that the large particles and part of the suspended sludge in the biogas slurry are precipitated, the precipitated part is treated as biogas residue, and the supernatant part is processed in the next step; (2 ) The supernatant after the sedimentation treatment is carried out in the nitrification reaction tank, and continuous aeration is carried out, so that the ammonia nitrogen in the biogas slurry is converted into nitrate nitrogen, and at the same time, part of the organic matter in the biogas slurry is degra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com