Method for analyzing chromium in ore sample

An analysis method and technology for ore samples, applied in the measurement of color/spectral characteristics, etc., can solve the problems of cumbersome, time-consuming and unsuitable oxidation process, and achieve the effect of excellent special effect, shortened analysis time and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

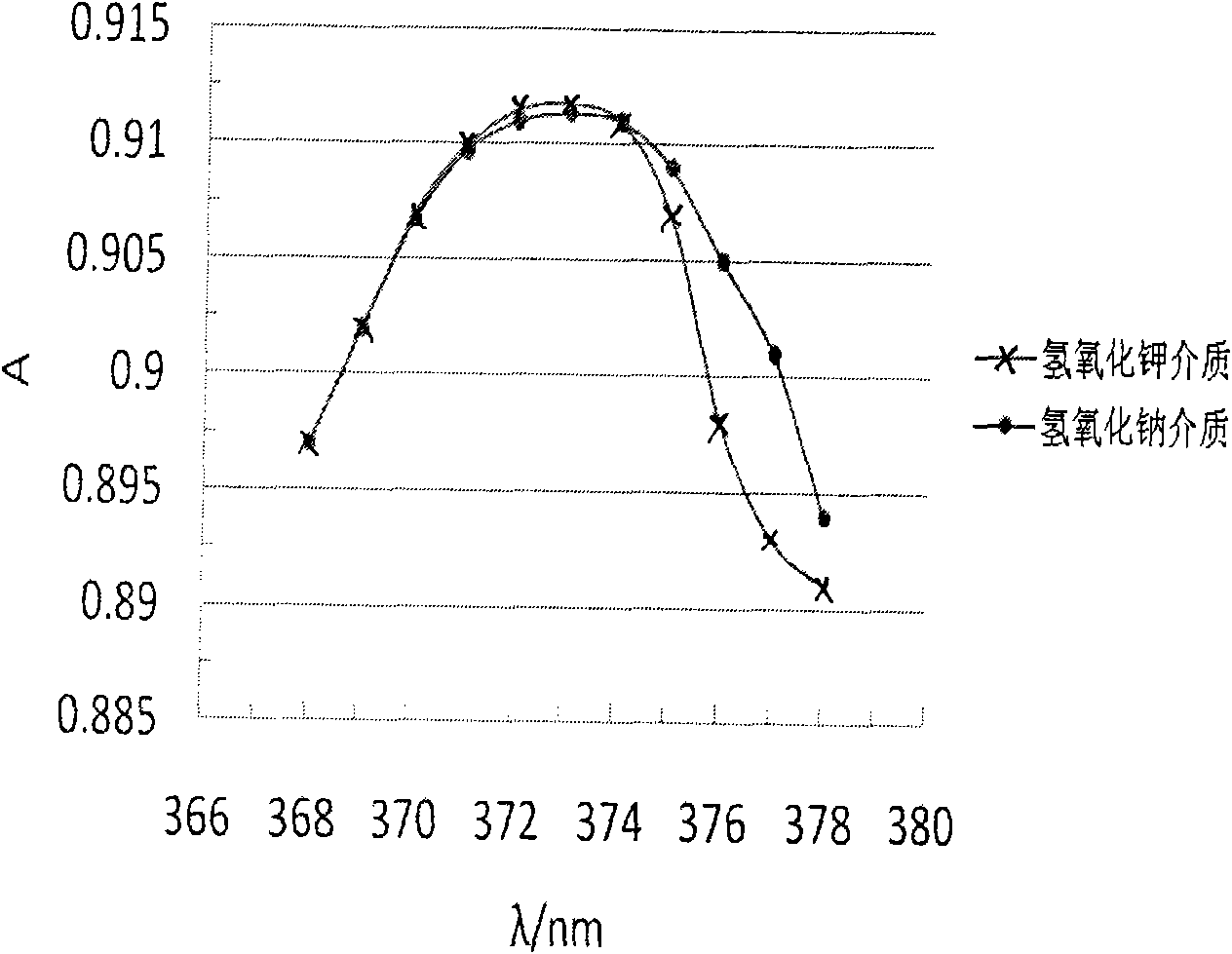

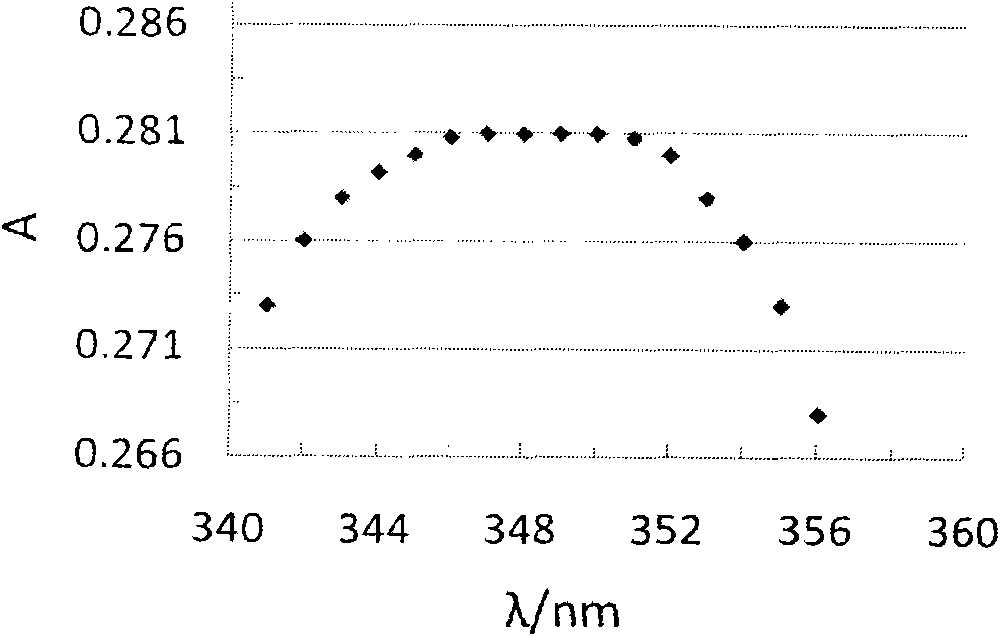

Method used

Image

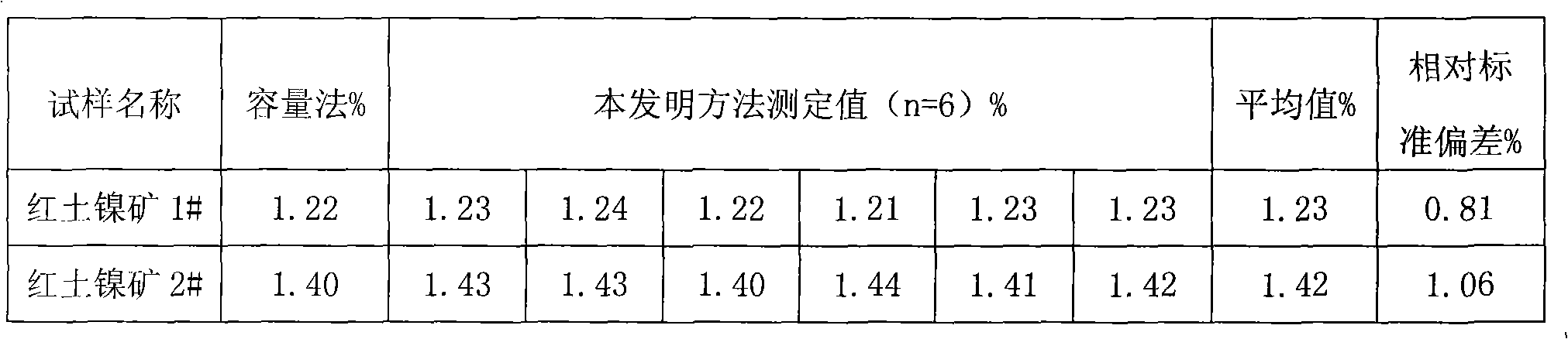

Examples

Embodiment 1

[0019] Weigh 0.1049g of sample into a nickel crucible containing 2g of potassium hydroxide, add a small amount of potassium nitrate, place in a muffle furnace and heat up to 750°C, melt for 20 minutes, take it out and put the nickel crucible into a 250ml beaker after cooling slightly , add 10ml of boiling water to extract the melt, and rinse the inner and outer walls of the crucible with boiling water, add 1ml of absolute ethanol, boil on an electric furnace for 10 minutes, transfer the solution to a 200ml volumetric flask after cooling, dilute to volume with water, and dry filter. Take 5.00ml of the filtrate, put it into a 100ml volumetric flask, dilute it with water to the mark, and carry out colorimetric measurement. The absorbance is 0.649, and the chromium content is 27.50%.

Embodiment 2

[0021] Weigh 0.1976g of sample into a nickel crucible containing 3g of potassium hydroxide, add a small amount of potassium nitrate, put it in a muffle furnace and melt it at 750°C for 20 minutes, take it out and put it into a 250ml beaker after cooling slightly, and add 10ml Extract the melt with boiling water, rinse the inner and outer walls of the crucible with boiling water, add 1ml of absolute ethanol, boil on an electric furnace for 10 minutes, transfer the solution to a 100ml volumetric flask after cooling, dilute to volume with water, and dry filter. Separately take 20.00ml of the filtrate, put it into a 100ml volumetric flask, dilute with water to the mark, and carry out colorimetric measurement. The absorbance is 0.524, and the chromium content is 1.46%.

Embodiment 3

[0023] Weigh 0.1896g of sample into a nickel crucible containing 2g of sodium peroxide, add a small amount of potassium nitrate, place in a muffle furnace and heat up to 700°C, melt for 15 minutes, take it out and put the nickel crucible into a 250ml beaker after cooling slightly , add 10ml of boiling water to extract the melt, add 1ml of absolute ethanol, boil on an electric furnace for 10 minutes, rinse the inner and outer walls of the crucible with boiling water, transfer the solution to a 100m1 volumetric flask after cooling, dilute to volume with water, and dry filter. Take 20.00ml of filtrate to a 100ml volumetric flask, dilute to the mark with water, and perform colorimetric measurement. The absorbance is 0.438, and the chromium content is 1.24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com