Fluorescent sensor for magnesium ions and preparation method thereof

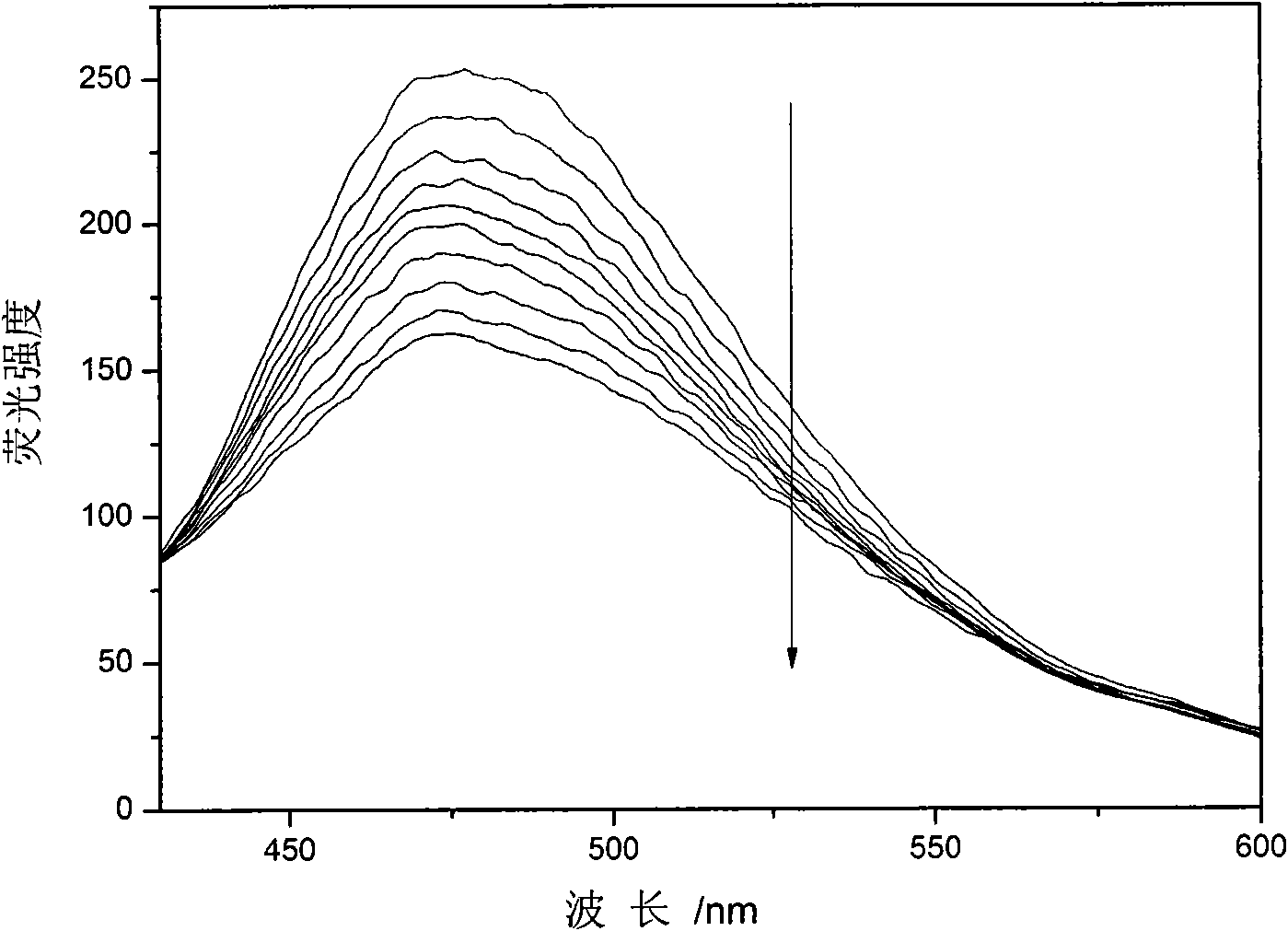

A fluorescence sensor, magnesium ion technology, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problem of weak research on thin film fluorescence sensor, improve thermal stability and pH applicable range, not easy to age, maintain optical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

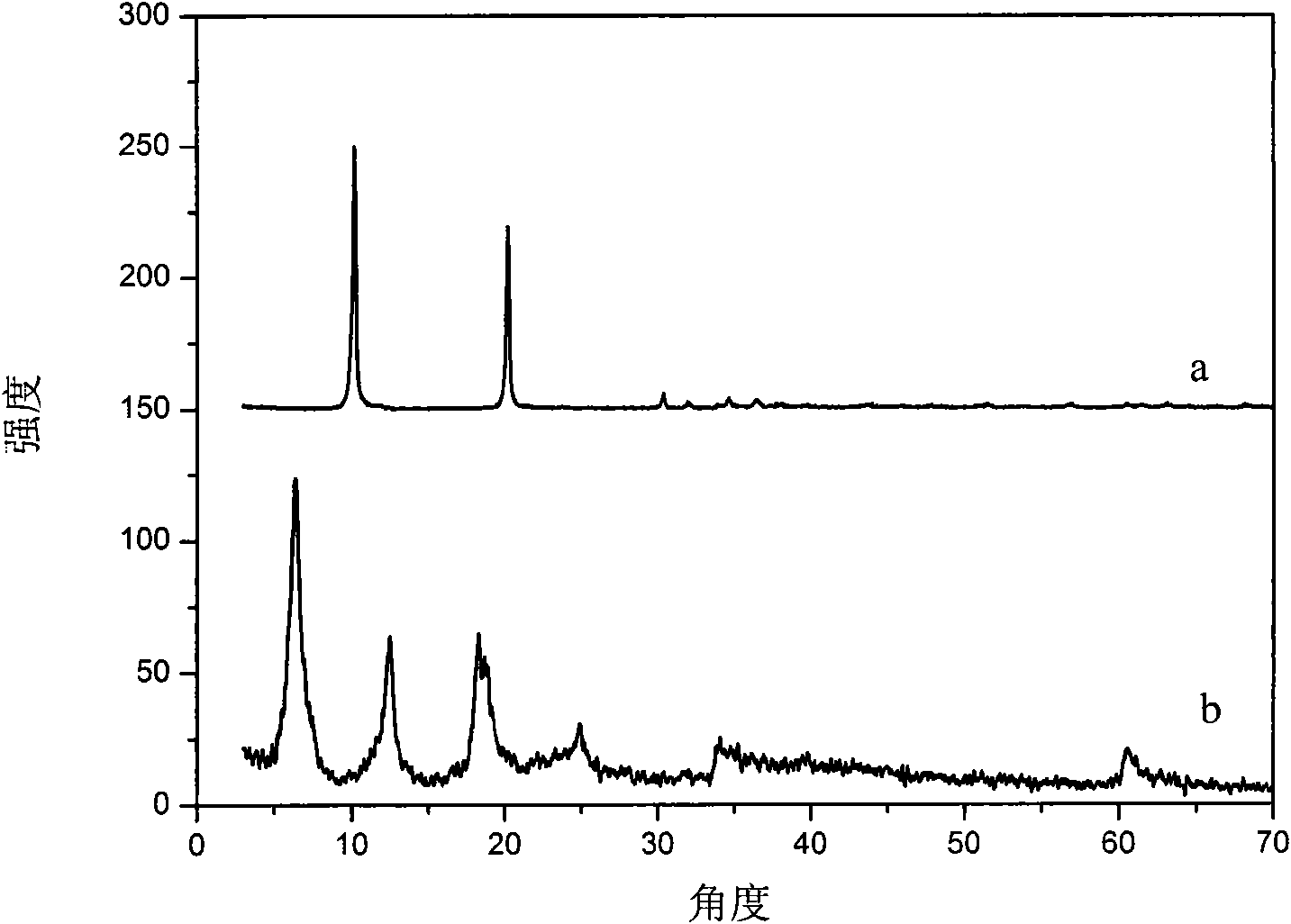

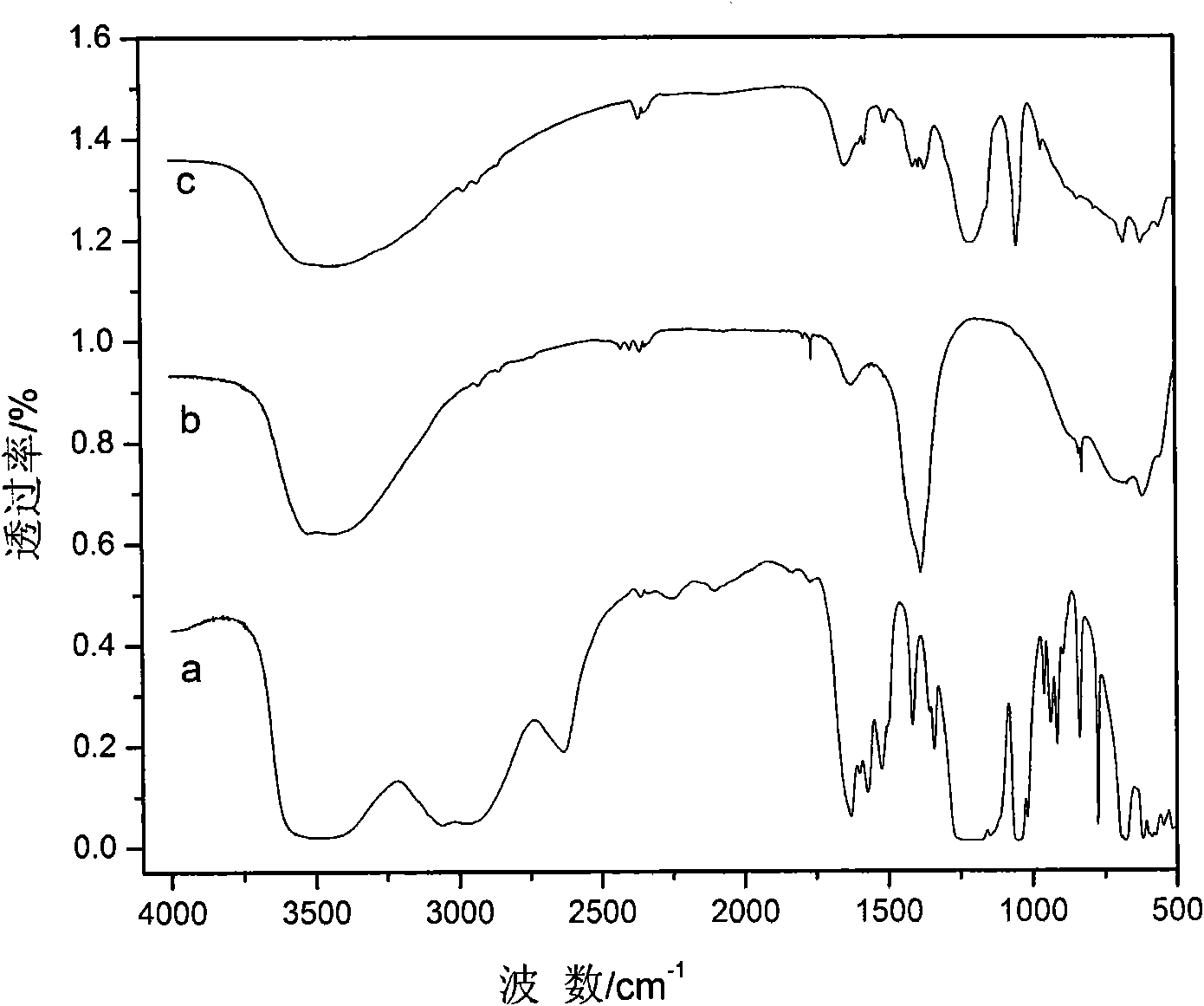

Method used

Image

Examples

Embodiment 1

[0023] a. Preparation of hydrotalcite precursor: adopt hydrothermal method, weigh 53.55g Zn(NO 3 ) 2 ·6H 2 O and 33.75gAL(NO 3 ) 3 9H 2 O dissolved in 100ml to remove CO 2 Prepare a saline solution in water; another 21.6g NaOH is dissolved in 100ml to remove CO 2 Prepare NaOH solution in water; add the salt solution and NaOH solution into a high-speed stirring colloid mill and stir for 1 minute to obtain a slurry; place the slurry in a pressure melting bomb, react at 110°C for 10 hours, and centrifuge and wash the product; The chemical formula of the prepared hydrotalcite precursor is Zn 2 Al(OH) 6 (NO 3 )·6H 2 O;

[0024] b. the preparation concentration is 1-naphthylamine-3,6,8-trisulfonic acid solution of 3g / L, after adjusting the pH value of the solution with sodium hydroxide to be 6.5, add the hydrotalcite precursor prepared by 0.5g step a, in N 2 Stir under protection, react at 25°C for 48 hours, the product uses CO 2 Washing with water and centrifuging to ob...

Embodiment 2

[0036] a. with the step a of embodiment 1;

[0037] b. the preparation concentration is 1-naphthylamine-3,6,8-trisulfonic acid solution of 5g / L, and the hydrotalcite precursor that 0.8g step a prepares after adding the hydrotalcite precursor of 0.8g step a with sodium hydroxide regulator solution pH value, in N 2 Stir under protection, react at 28°C for 48 hours, the product uses CO 2 Washing with water and centrifuging to obtain 1-naphthylamine-3,6,8-trisulfonic acid intercalated hydrotalcite;

[0038] c. Take 1 g of the 1-naphthylamine-3,6,8-trisulfonic acid intercalated hydrotalcite prepared in step b, dissolve it in 80 ml of ethanol solution and sonicate for 6 minutes, put the mixed solution in a high-speed centrifuge, and set the speed at 7500 rpm / min, centrifuged for 6 minutes, and took the upper colloidal solution;

[0039] d. Take 20ml of the upper colloidal solution obtained in step c and place it in the electrochemical deposition liquid pool. 2 The conductive gla...

Embodiment 3

[0041] a. with the step a of embodiment 1;

[0042] b. the preparation concentration is 1-naphthylamine-3,6,8-trisulfonic acid solution of 8g / L, the hydrotalcite precursor that 0.2g step a prepares after adding the hydrotalcite precursor of 0.2g step a with sodium hydroxide regulator solution pH value, in N 2 Stir under protection, react at 30°C for 48 hours, the product uses CO 2 Washing with water and centrifuging to obtain 1-naphthylamine-3,6,8-trisulfonic acid intercalated hydrotalcite;

[0043] c. Take 1 g of 1-naphthylamine-3,6,8-trisulfonic acid intercalated hydrotalcite prepared in step b, dissolve it in 90 ml of ethanol solution and sonicate for 12 minutes, put the mixed solution in a high-speed centrifuge, and set the speed at 7500 rpm / min, centrifuged for 9 minutes, and got the upper colloidal solution;

[0044] d. Take 20ml of the upper colloidal solution obtained in step c and place it in the electrochemical deposition liquid pool. 2 The conductive glass FTO s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com