Preparation method and application of multifunctional SnO2@C composite nanometer material

A composite nanomaterial and multi-purpose technology, applied in the field of multi-purpose SnO2@C composite nanomaterial preparation, can solve the problems of complexity, high production cost and equipment cost, complicated process, etc., achieve good reproducibility, convenient operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 0.005mol tin tetrachloride is dissolved in a mixed solvent of 30 milliliters of ethanol and 20 milliliters of ethylene glycol to form a homogeneous solution. The homogeneous solution is ignited, and the temperature during combustion is 400-500°C. After the solution is completely burned, to form SnO 2 @C, the yield is 95.8%.

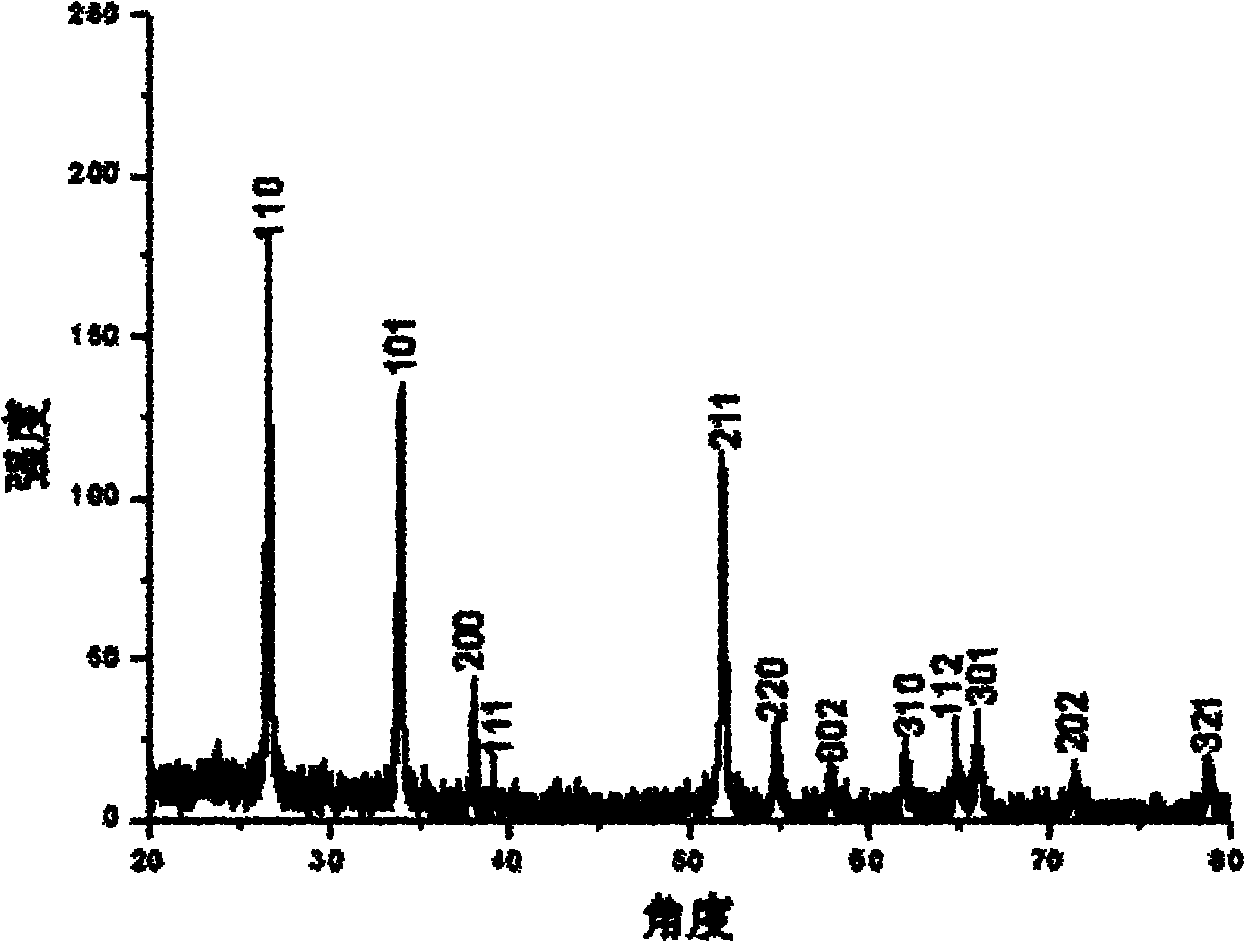

[0042] Carry out phase identification to the product that embodiment 1 generates with Japan Shimadzu XRD-6000 type X-ray powder diffractometer (Cu target, Kα ray, λ=0.154060nm, scanning speed 0.02 ° / S), its XRD pattern (X-ray powder diffraction pattern), such as figure 1 shown. The diffraction peaks of all X-ray diffraction patterns compared with the JCPDS standard card (41-1445) can be consistent with the tetragonal tin dioxide. Strong diffraction peaks indicate that SnO 2 is highly crystalline. exist figure 1 In the X-ray diffraction pattern, no characteristic absorption peaks of impurities were found, which indicated that the prepared prod...

Embodiment 2

[0046] 0.005mol of tin tetrachloride is dissolved in 50ml of ethanol to form a homogeneous solution. The homogeneous solution is ignited. The temperature during combustion is 400-500°C. After the solution is completely burned, SnO can be formed. 2 @C.

[0047] Get 0.1g of the product produced in Example 2 in 20ml of ethanol, after ultrasonic dispersion in an ultrasonic cleaner for 5min, drop it on a copper sheet and dry it in the air; adopt a Japanese Hitachi S-4800 type field emission scanning electron microscope to analyze the initial particle size and shape Looks like Figure 2b shown.

Embodiment 3

[0049] 0.005 mol of tin tetrachloride is dissolved in a mixed solvent of 20 milliliters of ethanol and 30 milliliters of ethylene glycol to form a homogeneous solution. The homogeneous solution is ignited, and the temperature during combustion is 400-500 ° C. After the solution is completely burned, to form SnO 2 @C.

[0050] Get 0.1g embodiment 3 produced product in 20ml ethanol, after ultrasonic dispersion 5min in the ultrasonic cleaner, be dropped on the copper sheet and dry; Adopt Japan Hitachi S-4800 type field emission scanning electron microscope to analyze particle primary particle size and shape Looks like Figure 2c shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com