System and method for recycling and supplying mortar to multi-wire cutting machines

A multi-wire cutting machine and supply system technology, applied in the direction of work accessories, stone processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, solid substances brought into the mortar, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

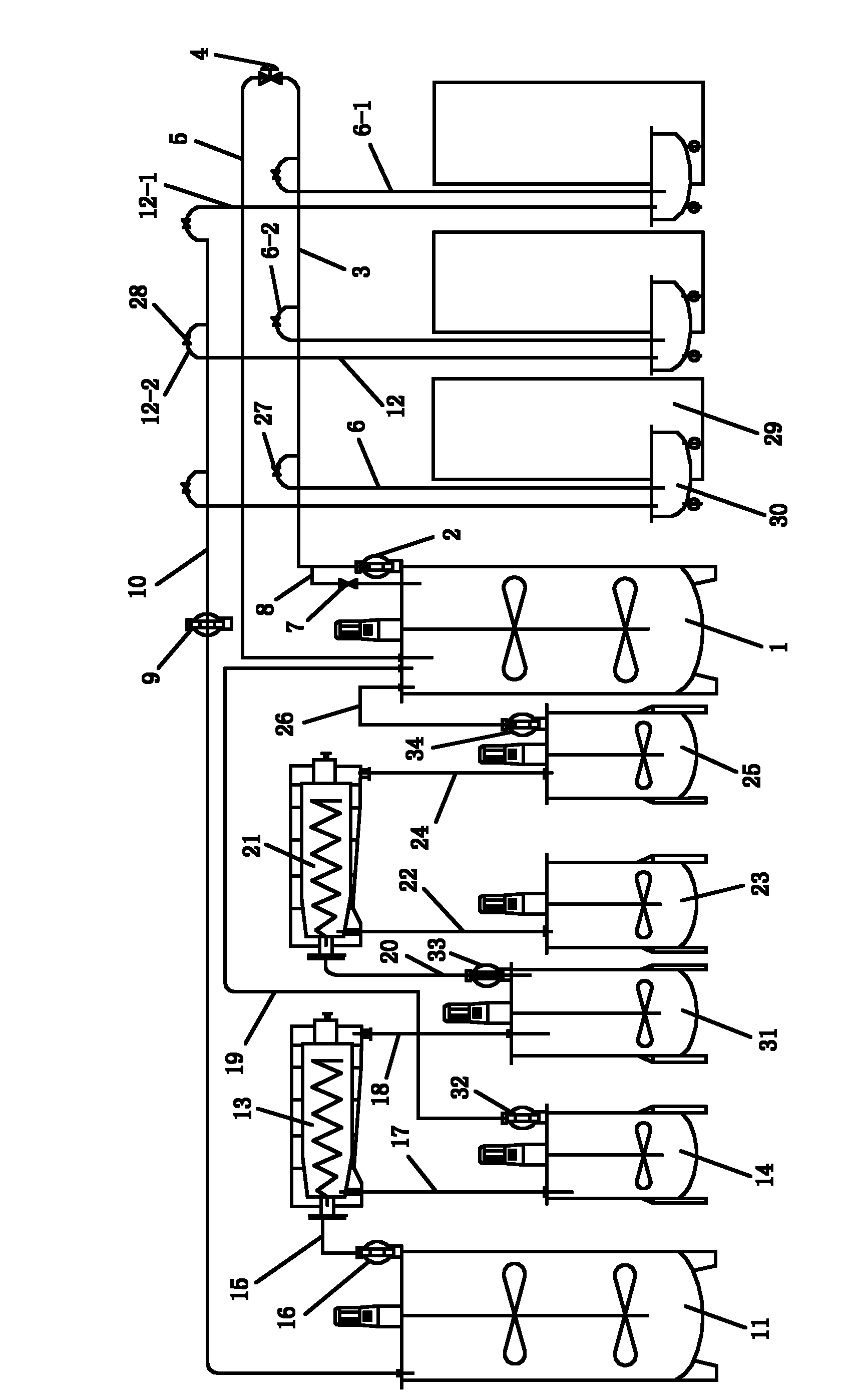

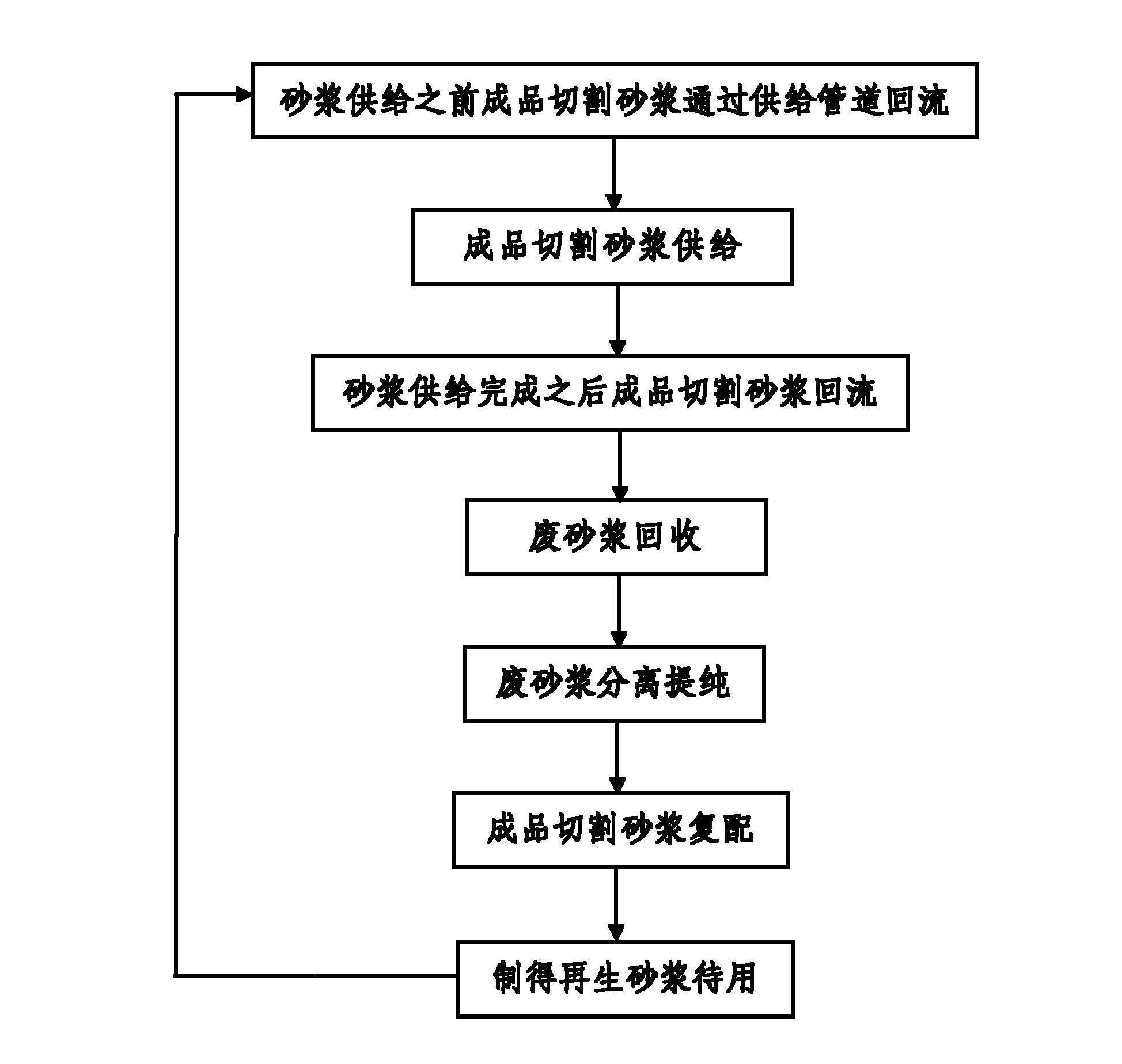

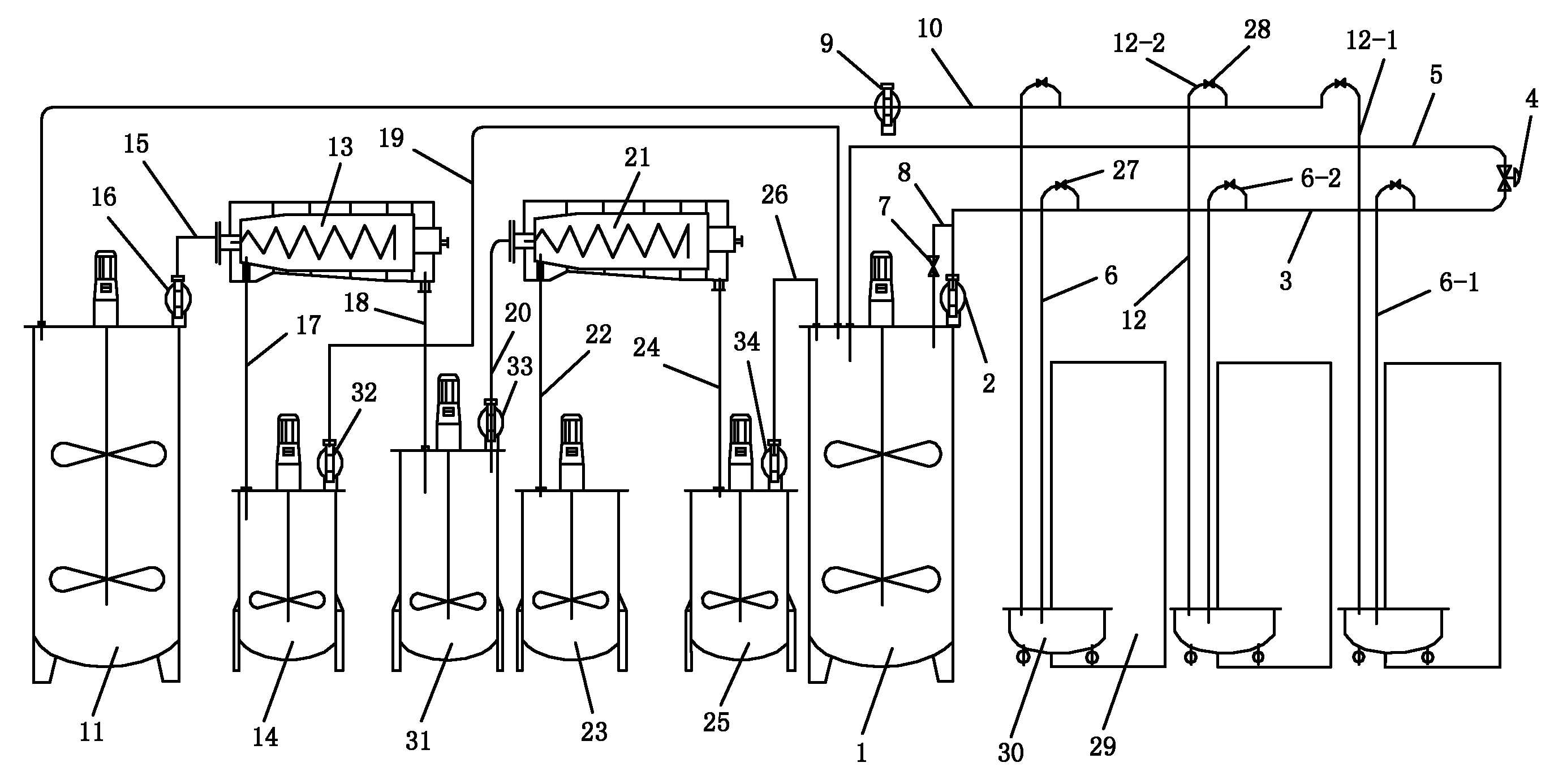

[0066] Such as figure 1 A mortar circulation and supply system for a multi-wire cutting machine is shown, including a finished mortar storage tank 1, a main supply pipeline 3, an auxiliary return pipeline 5, a branch supply pipeline 6, a waste liquid return main pipe 10, and a waste liquid return branch The pipeline 12, the waste liquid recovery tank 11 that recovers and stores the waste mortar after cutting by the multi-wire cutting machine 29, separates and purifies the waste mortar and extracts the reusable silicon carbide and silicon carbide that can be put into use again in the waste mortar Waste mortar separation and purification equipment for reusable slurry, silicon carbide thick slurry storage tank 14 and recovery liquid storage tank 25 for storing reusable silicon carbide and reusable slurry respectively, storage tank 14 for storing silicon carbide thick slurry The silicon carbide thick slurry pumping pipeline 19 that can re-use the silicon carbide thick slurry to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com