Light-burned dolomite cement

A light-burned dolomite and light-burned dolomite powder technology, applied in the cement field, can solve the problems of not being able to pack cement products, not belonging to cement cementitious materials, and consuming magnesite resources, so as to promote resource utilization and comprehensive utilization, overcome The effect of moisture absorption and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: lightly burned dolomite cement of the present invention, its preparation method may further comprise the steps:

[0023] (1) Raw material metering: lightly burned dolomite powder, industrial waste residue, reinforcing thickener, and water-resistant admixture are metered respectively according to the formulas in Examples 2-9;

[0024] (2) mixing and grinding: the measured raw materials are mixed evenly, and stirred to make light-burned dolomite cement;

[0025] (3) Moisture-proof packaging: packed in paper bags or woven bags lined with plastic film, and leave the factory.

[0026] When in use, any one or a mixed solution of the magnesium chloride solution with a Baume degree of 18 to 35°Bé and the magnesium sulfate solution with a Baume degree of 20 to 35°Bé is used for stirring.

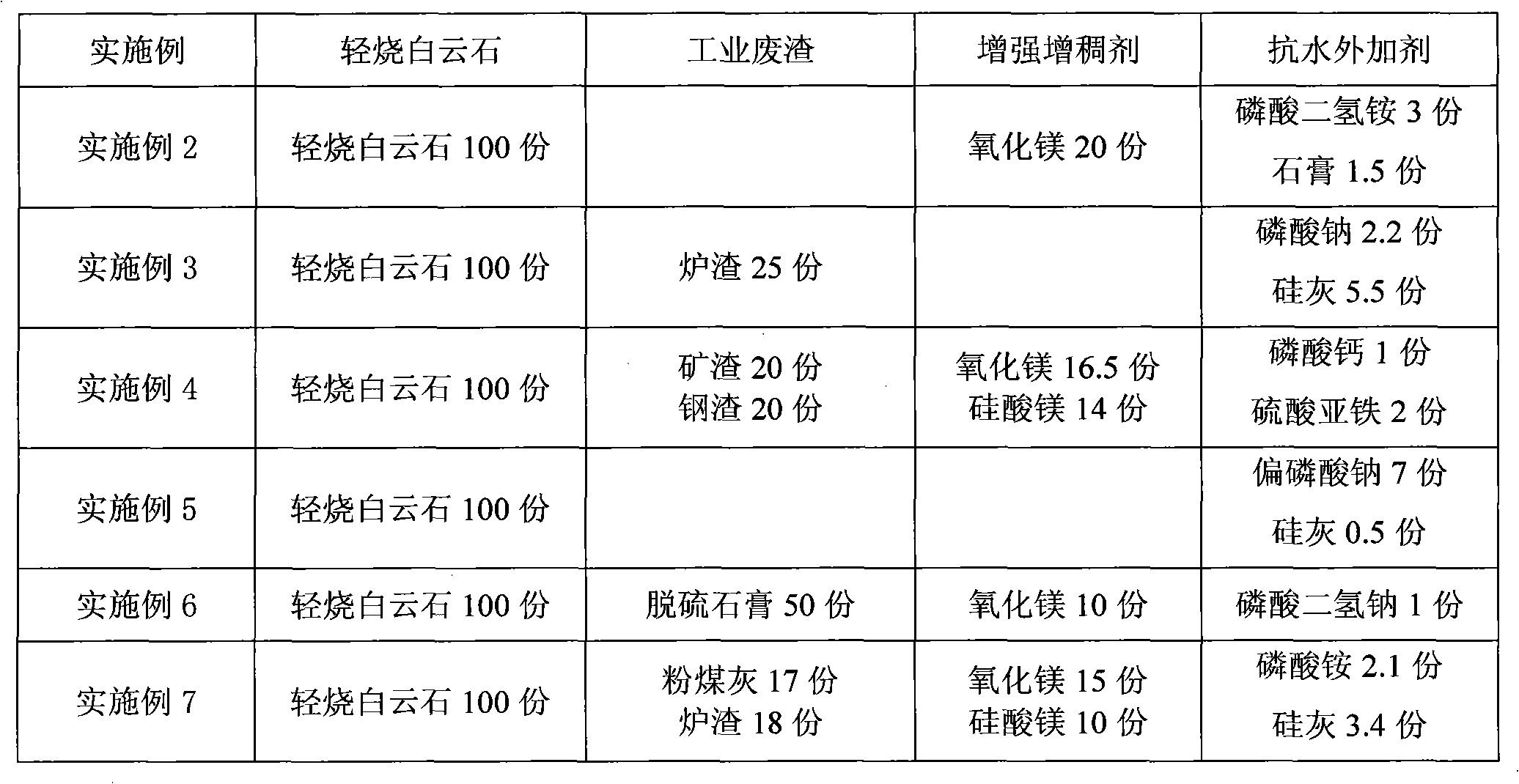

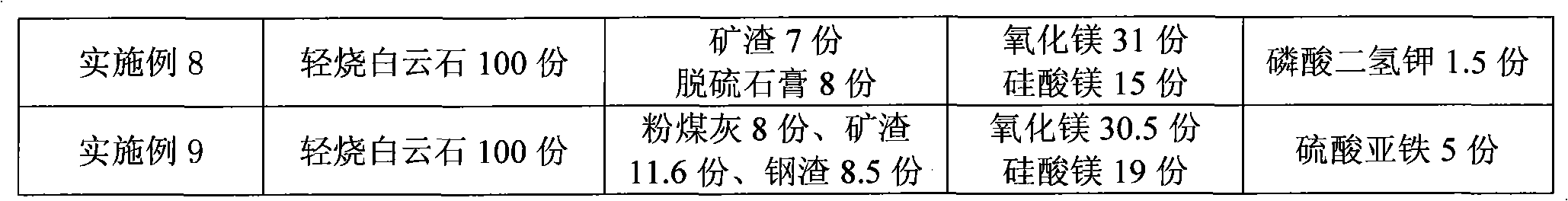

[0027] Embodiment 2-9 is as shown in table 1:

[0028] The light-burned dolomite cement in Examples 2-9 was prepared using the method of Example 1 and the formula in the follow...

Embodiment 10

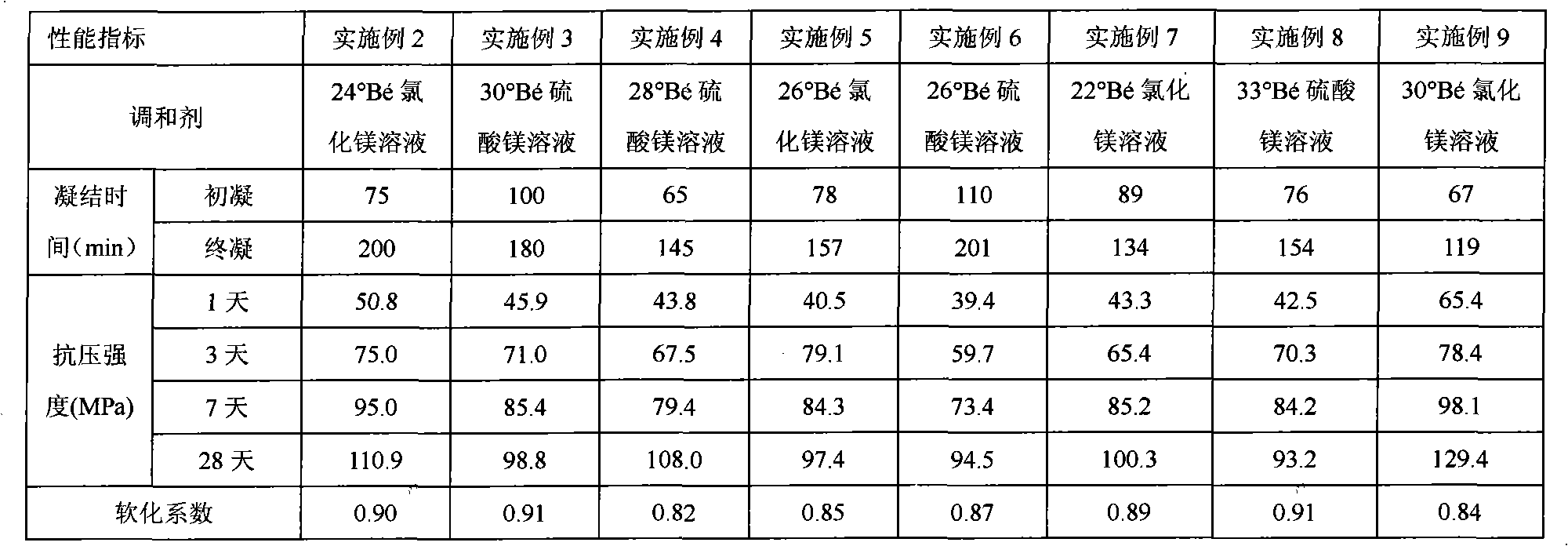

[0032] Example 10: The properties of light-burned dolomite cement prepared with the formula of Examples 2-9 were tested, and the results are shown in Table 2.

[0033] Table 2: The performance test table of the lightly burned dolomite cement prepared by the formula of embodiment 2-9

[0034]

[0035] As can be seen from the data in Table 2, the present invention has the characteristics of fast setting, early strength, high strength, and water resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com