Method for separating and purifying by-product trimethyl thiophosphate

A technology of trimethyl phosphorothioate and by-products, which is applied in the field of separation and purification of trimethyl phosphorothioate by-products, and can solve the difficulty of comprehensive utilization of trimethyl esters due to lack of attention to separation and purification of trimethyl esters, which affects product yield , by-products increase the cost of wastewater treatment, etc., to meet the effect of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

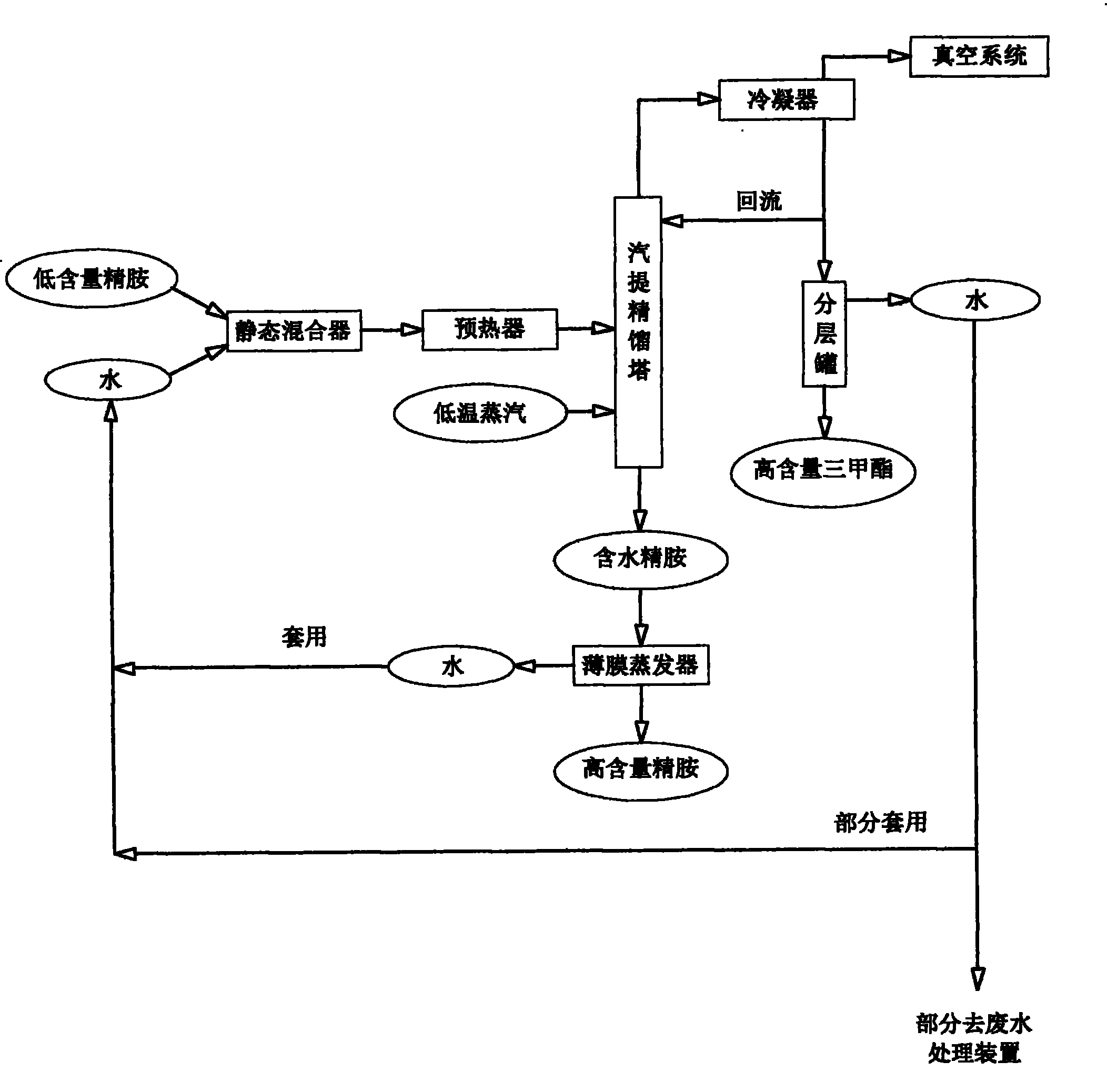

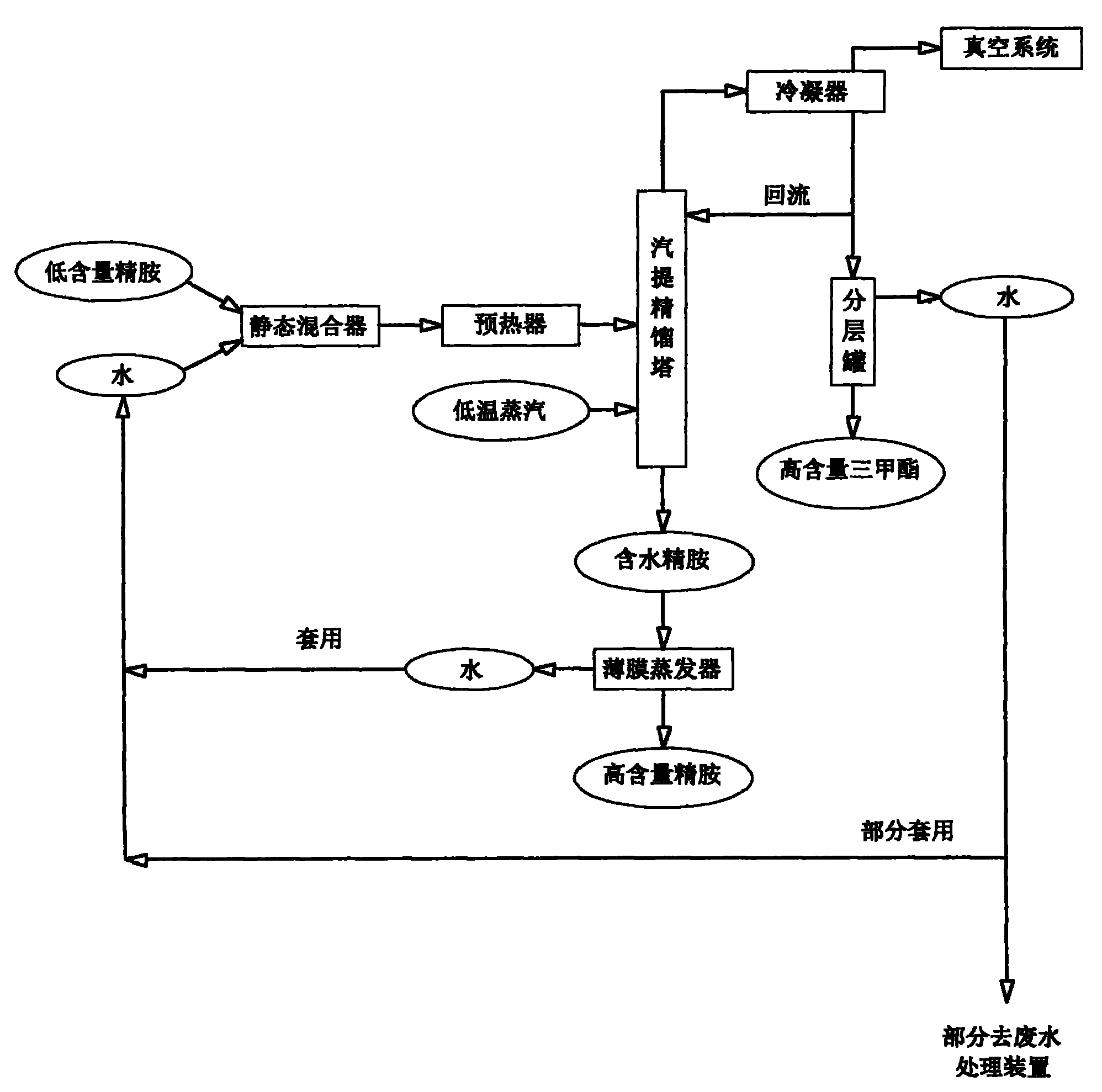

Method used

Image

Examples

Embodiment 1

[0017] a. The fully washed methyl chloride amination reaction product (wherein the content of spermine is 91.6%, the content of trimethyl ester is 8.2%, and the unknown impurity is 0.2%) with a flow rate of 2.5m 3 / h, with 0.55m 3 After the water per hour is fully mixed by the static mixer, the condensed water recovered by the preheater and the methanol tower is heat-exchanged to 70-75°C;

[0018] b, enter the middle part of the stripping rectification tower, the vacuum degree of the stripping tower is controlled at -0.085~-0.088MPa with a vapor-liquid ratio of 2:1, the temperature is 60~65°C, and the reflux ratio is 1:5 to carry out vacuum stripping and distillation;

[0019] c. The gas phase is discharged from the top of the rectifying section, enters the top condenser to condense, and the condensate enters the stratified tank;

[0020] d, the upper part is separated to obtain a part of the water phase to enter the water storage tank for mechanical use, and the other part ...

Embodiment 2

[0024] a. The low-concentration O, O-dimethylphosphorothioate solution recovered after evaporation by the lifting film and thin film evaporator, wherein spermine (83.7% content, 15.7% trimethyl ester content, 0.6% unknown impurity) in the flow rate 2.0m 3 / h, with 1.2m 3 After the water per hour is fully mixed by the static mixer, the condensed water recovered by the preheater and the methanol tower is heat-exchanged to 75-80°C;

[0025] b. Enter the middle part of the stripping and rectifying tower, and the stripping tower is controlled at a vapor-liquid ratio of 1.3 to 1.4:1, a vacuum of -0.07 to -0.075MPa, a temperature of 65 to 70°C, and a reflux ratio of 1:2 for decompression Stripping and distillation;

[0026] c. The gas phase is discharged from the top of the rectifying section, enters the top condenser to condense, and the condensate enters the stratified tank;

[0027] d, the upper part is separated to obtain a part of the water phase to enter the water storage ta...

Embodiment 3

[0031] a. The low-concentration O, O-dimethylphosphorophosphoramide solution recovered after evaporation by lift-off film and thin-film evaporator, wherein spermine (content 77.5%, trimethyl ester content 22.8%, unknown impurity 0.7%) with flow rate 2.0m 3 / h, with 2.0m 3 After the water per hour is fully mixed by the static mixer, the condensed water recovered by the preheater and the methanol tower is heat-exchanged to 85-90°C;

[0032] b. Enter the middle part of the stripping and rectifying tower, and the stripping tower is controlled at a vapor-liquid ratio of 1.6 to 1.8:1, a vacuum of -0.06 to -0.065MPa, a temperature of 70 to 75°C, and a reflux ratio of 1:1.25 for decompression. Stripping and distillation;

[0033] c. The gas phase is discharged from the top of the rectifying section, enters the top condenser to condense, and the condensate enters the stratified tank;

[0034] d, the upper part is separated to obtain a part of the water phase to enter the water stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com