Polymer nano hydrogel and preparation method thereof

A nano-hydrogel, polymer technology, applied in the field of hydrogel, can solve problems such as limitations, and achieve the effects of good stability, good degradability, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

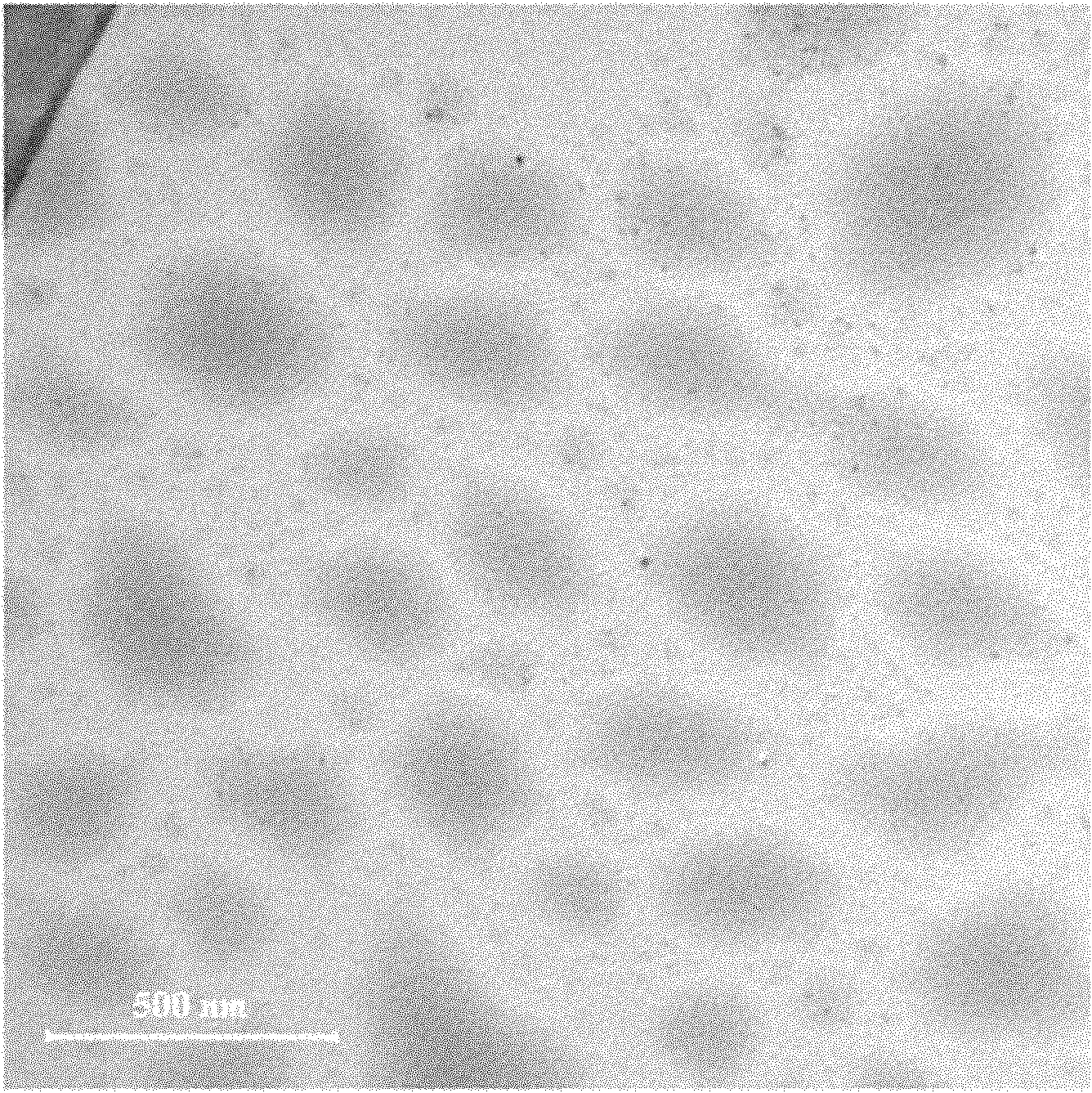

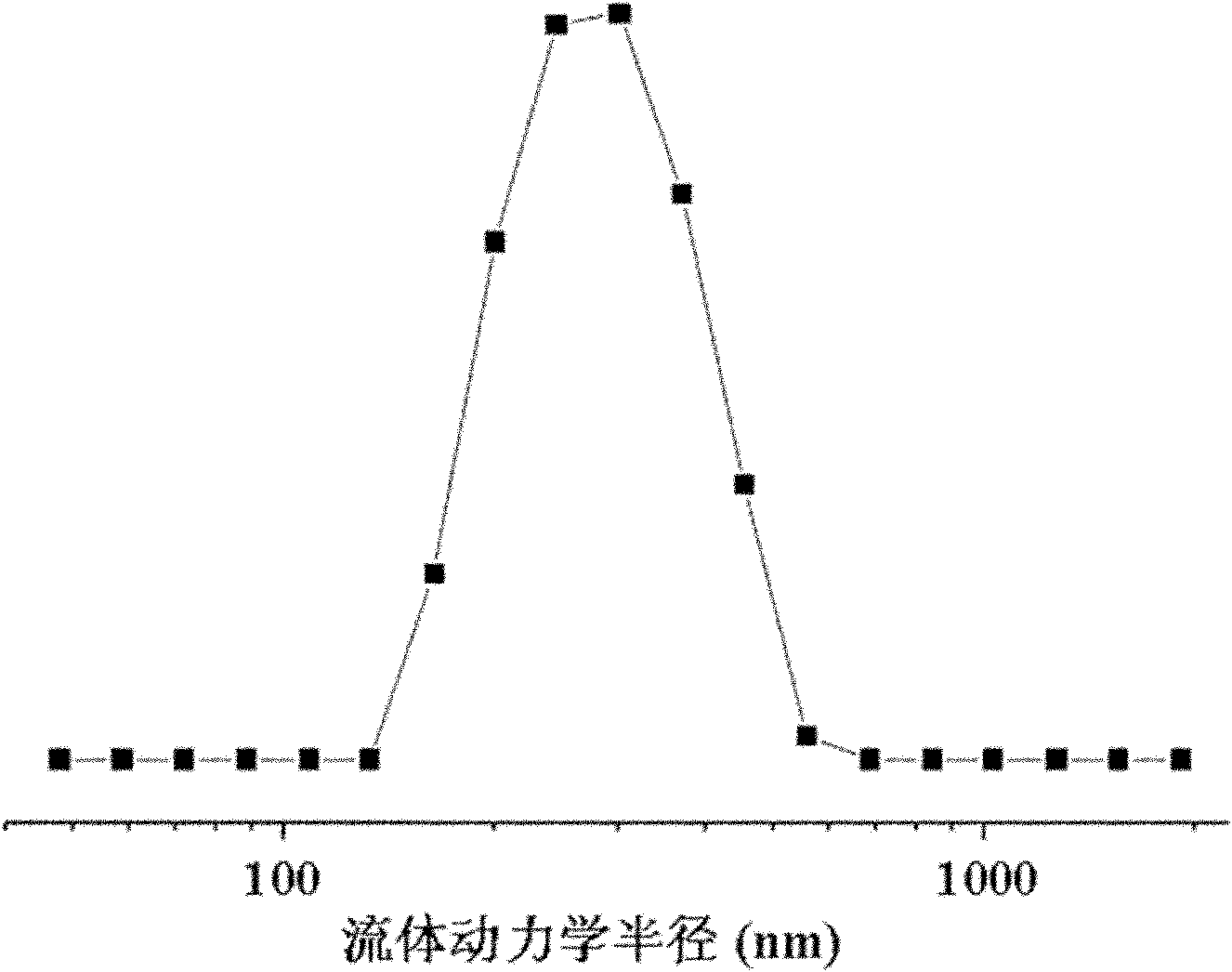

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing the polymer nanohydrogel described in the above technical solution, comprising:

[0047] a) Mix the hydrophilic polymer, triethylamine and chloryl chloride, stir and react to obtain the first intermediate product, the hydrophilic polymer is polyethylene glycol or polyethylene glycol monomethyl ether, and the chloroyl chloride has the formula (IV) Structure:

[0048]

[0049] Among them, 1≤t≤65;

[0050] b) dissolving the first intermediate product and poly(L-glutamate)-b-poly(γ-2-chloroethyl-L-glutamate) in an organic solvent, adding sodium perselenide Aqueous solution, under anaerobic conditions for cross-linking reaction, after dialysis to obtain polymer nano hydrogel.

[0051] The present invention first uses hydrophilic polymer, triethylamine and chloryl chloride as raw materials to prepare terminal chlorine-functionalized hydrophilic compounds, that is, the first intermediate product, and then uses sod...

Embodiment 1~5

[0091] The preparation of the polyethylene glycol monomethyl ether of embodiment 1~5 end group chlorine functionalization

[0092] According to the consumption of each raw material in Table 1, prepare the polyethylene glycol monomethyl ether of terminal chlorine functionalization according to the following method:

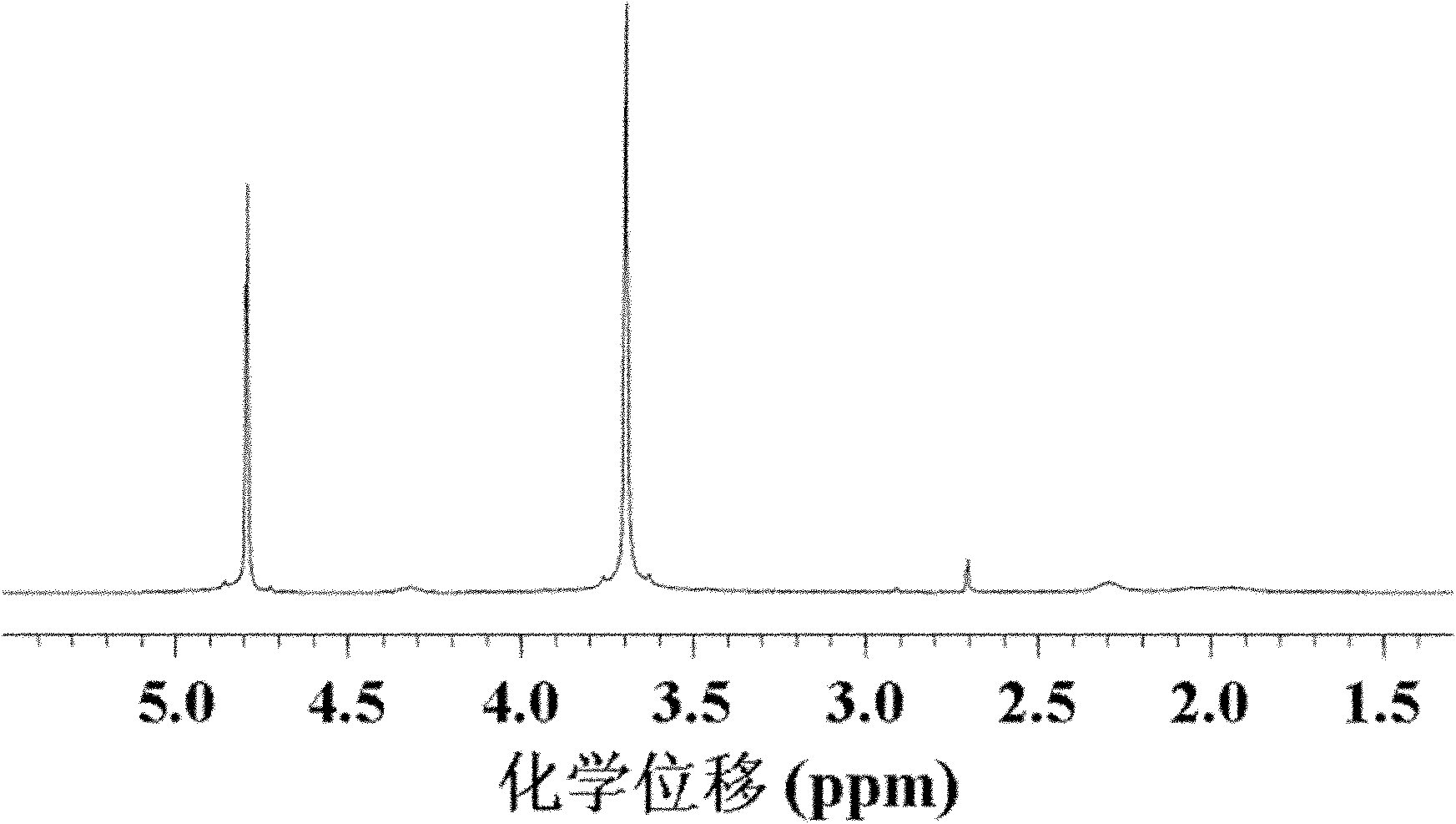

[0093] Add 10g of polyethylene glycol monomethyl ether and 100mL of toluene to the reaction bottle, after azeotropic dehydration, dissolve the obtained product in 100mL of anhydrous dichloromethane, add triethylamine after cooling to 0°C, and then dropwise add chlorine Propionyl chloride, react at 0°C for 2 hours, then heat up to 25°C, and continue to react for 24 hours under stirring with a stirrer. After the reaction is completed, filter the reaction mixture, and after the filtrate is obtained, it is settled with ether, filtered, washed, and vacuum-dried at 25°C for 24 hours to obtain Polyethylene glycol monomethyl ether chloropropionate. Carry out nuclear magne...

Embodiment 6

[0098] The preparation of embodiment 6 polyethylene glycol monomethyl ether chloroacetate

[0099] Add 10g of polyethylene glycol monomethyl ether with a number average molecular weight of 5000 and 100mL of toluene to the reaction flask, and after azeotropic dehydration, dissolve the obtained product in 100mL of anhydrous dichloromethane, cool to 0°C and add 1.01g Triethylamine, then add 4.52g of chloroacetyl chloride dropwise, react at 0°C for 2h, then raise the temperature to 25°C, continue to react for 24h under the stirring of the stirring bar, after the reaction is completed, filter the reaction mixture, and after the filtrate is obtained, settling and filtering with diethyl ether , washing, and vacuum drying at 25° C. for 24 hours to obtain polyethylene glycol monomethyl ether chloroacetate, the number average molecular weight of the polyethylene glycol monomethyl ether chloroacetate is 5076, and the reaction yield is 92.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com