Preparation method of solid acid esterification catalyst

A technology of esterification and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low catalytic activity of solid acid, inability to catalyze esterification reaction, affecting catalyst activity, etc. To achieve the effect of strong acidity, low production cost and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

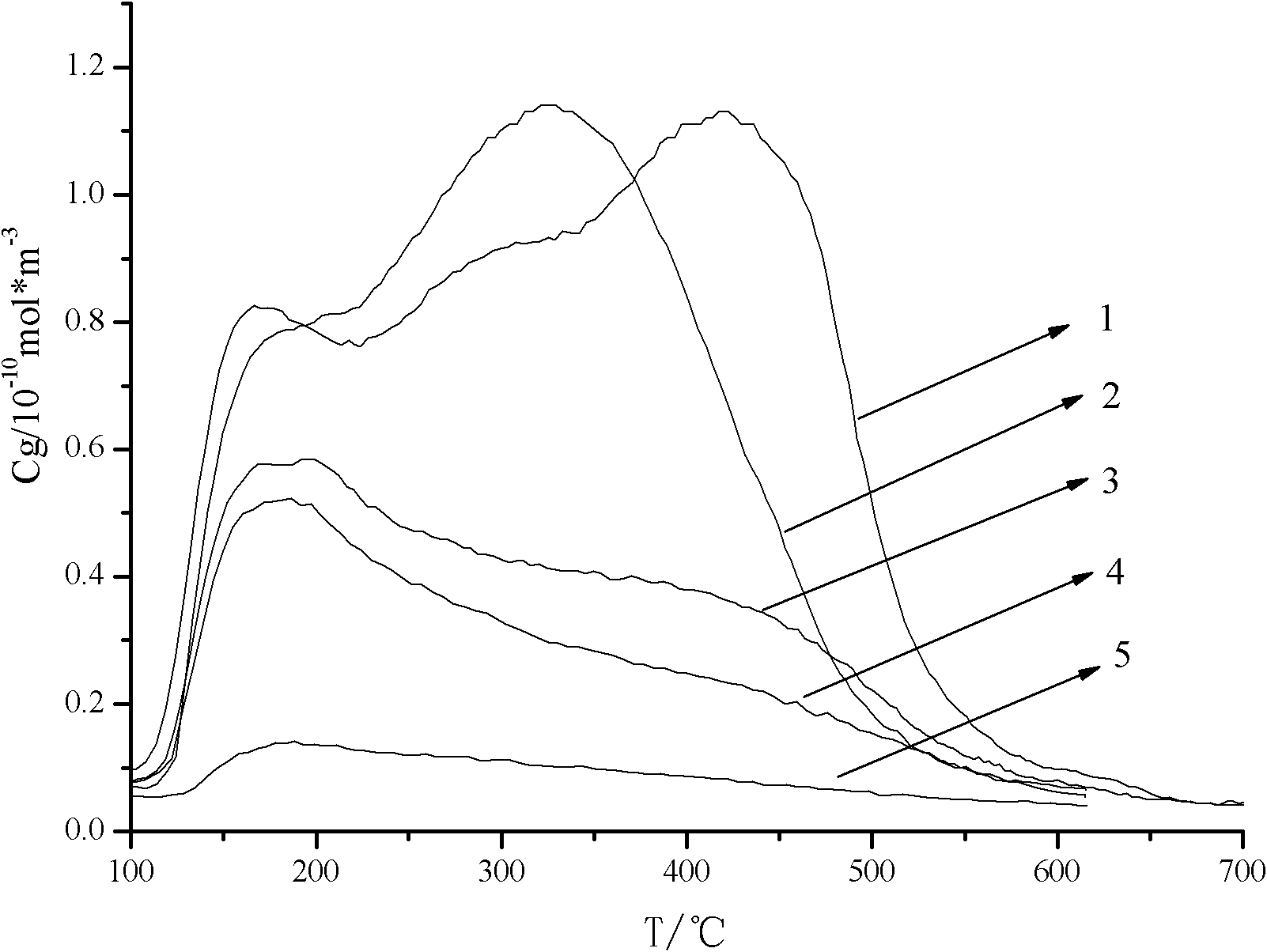

Image

Examples

Embodiment 1

[0025] 0.1mol / L of ZrO(NO 3 ) 2 Solution 200ml and mass fraction are 25%~28% concentrated ammonia water 26ml, add dropwise and stir simultaneously, ZrO(NO 3 ) 2 The ratio of the rate of addition of the solution to the concentrated ammonia water is 8: 1, and the pH value of the control is 9 to produce Zr(OH) 4 Precipitation, aging for 1 h, filtration, and vacuum drying to obtain a zirconium hydroxide precursor. Then impregnate 0.5mol / gH according to 15ml / g zirconium hydroxide precursor 2 SO 4 The ratio of the solution, the zirconium hydroxide precursor is impregnated, dried and calcined in a muffle furnace at 550°C for 3h to obtain SO 4 2- / ZrO 2 solid acid catalyst.

[0026] will get SO 4 2- / ZrO 2 Solid acid catalyst is used for the esterification reaction of higher fatty acid oleic acid and glycerin, in reactor, add 26.7g oleic acid, 90ml soybean oil, 45ml n-butanol, 45ml glycerol, at normal pressure, under 140 ℃, add 1wt% solid Acid Catalyst SO 4 2- / ZrO 2 , ...

Embodiment 2

[0028] Under stirring at room temperature, 0.5mol / L of ZrO(NO 3 ) 2 200ml of the solution and 130ml of concentrated ammonia water with a mass fraction of 25% to 28%, were added dropwise and stirred simultaneously, ZrO(NO 3 ) 2 The ratio of the rate of addition of the solution to the concentrated ammonia water is 1.5: 1, and the pH value of the control is 8 to produce Zr(OH) 4 Precipitation, aging for 8 hours, filtration, and vacuum drying to obtain a zirconium hydroxide precursor. Then impregnate 1mol / g H with 10ml / g zirconium hydroxide precursor 2 SO 4 The ratio of the solution, the zirconium hydroxide precursor is impregnated, dried and calcined in a muffle furnace at 650°C for 3h to obtain SO 4 2- / ZrO 2 solid acid catalyst.

[0029] will get SO 4 2- / ZrO 2 The solid acid catalyst was used for the esterification reaction of higher fatty acid oleic acid and glycerin, carried out according to the method described in Example 1, and the esterification rate was 78% af...

Embodiment 3

[0031] Under stirring at room temperature, 1mol / L of ZrO(NO 3 ) 2 Solution 200ml and mass fraction are 25%~28% concentrated ammonia water 260ml, add dropwise and stir simultaneously, ZrO(NO 3 ) 2 The ratio of the rate of addition of the solution to the concentrated ammonia water is 1: 1.3, and the pH value of the control is 10 to produce Zr(OH) 4 Precipitation, aging for 24 hours, filtration, and vacuum drying to obtain a zirconium hydroxide precursor. Then impregnate 1mol / g H with 15ml / g zirconium hydroxide precursor 2 SO 4 The ratio of the solution, the zirconium hydroxide precursor is impregnated, dried and calcined in a muffle furnace at 800°C for 3h to obtain SO 4 2- / ZrO 2 solid acid catalyst.

[0032] will get SO 4 2- / ZrO 2The solid acid catalyst was used for the esterification reaction of higher fatty acid oleic acid and glycerin, carried out according to the method described in Example 1, and the esterification rate was 69% after 4 hours of reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com