Continuous casting forming equipment and process method for electromagnetic ejection filling core of cladding material

A technology of core-filling continuous casting and forming equipment, which is applied in the field of continuous casting processing of metal materials to achieve the effect of low production cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

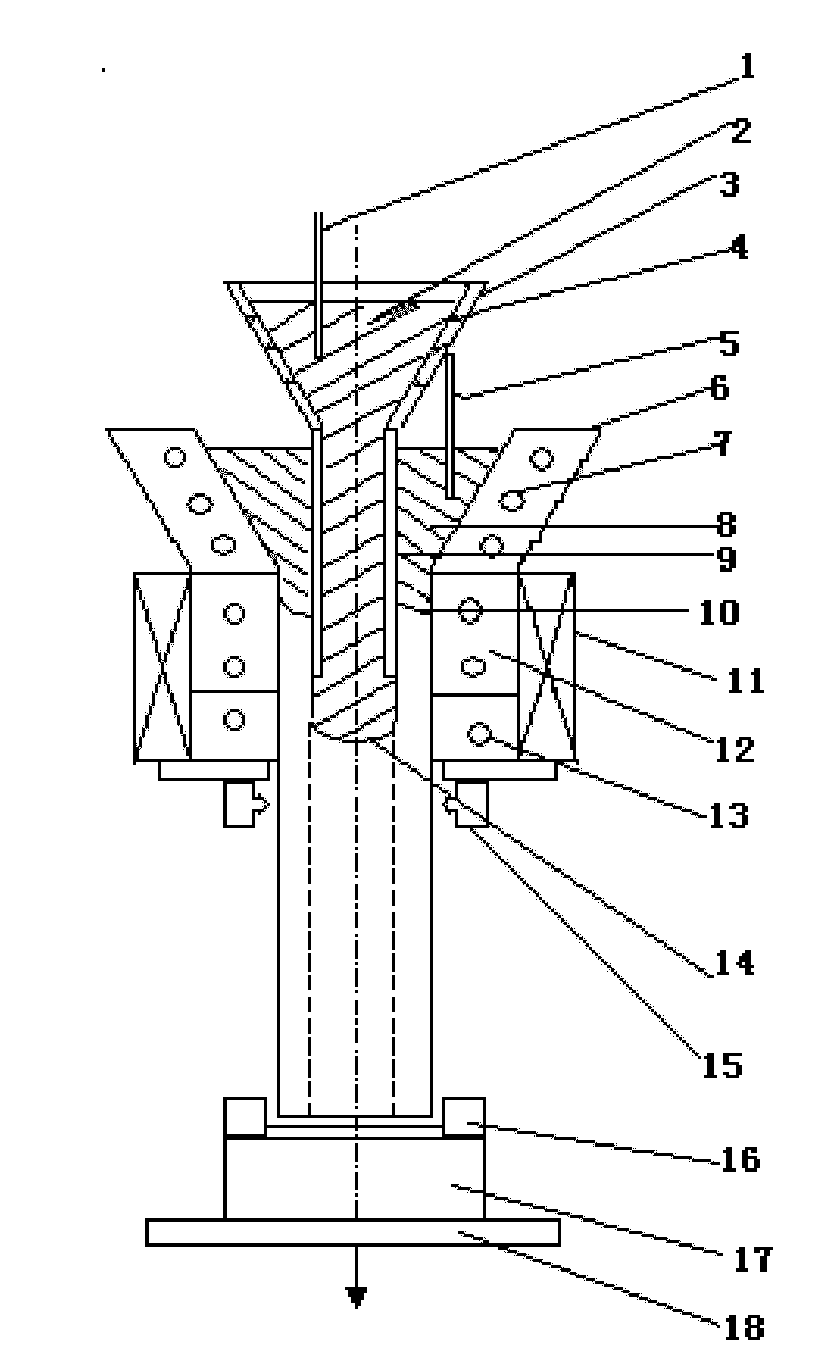

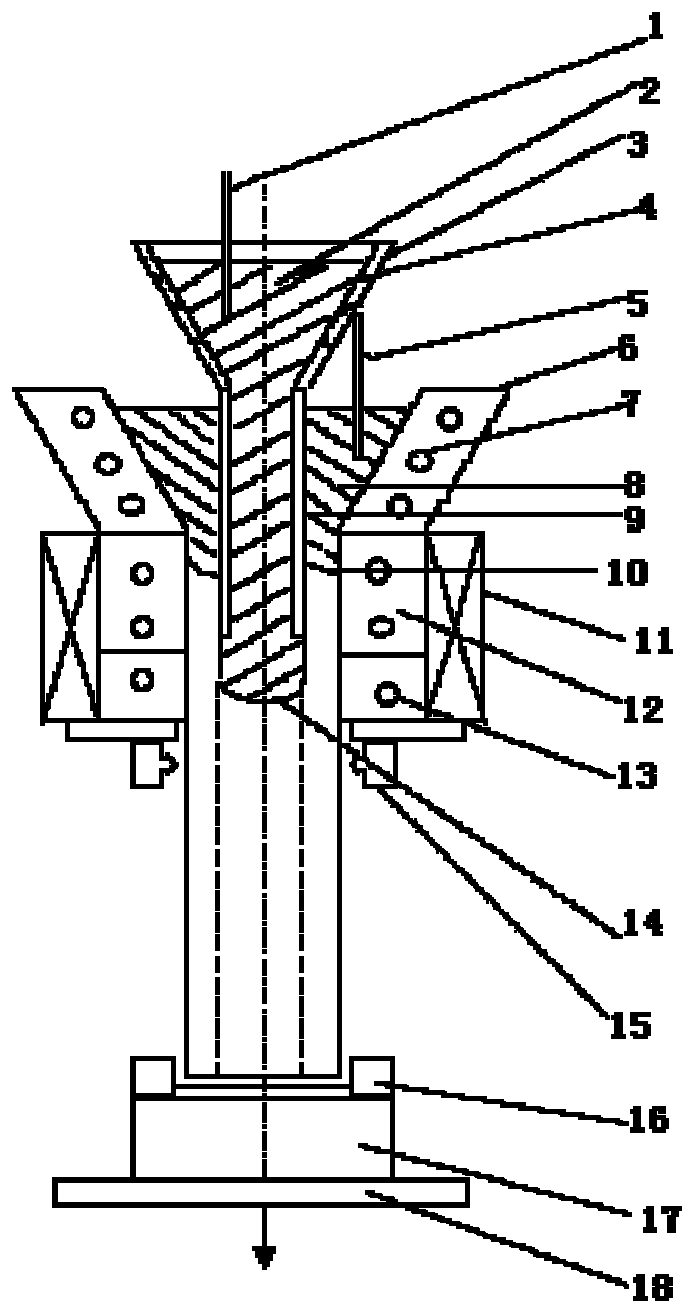

[0025] Electromagnetic ejection core filling continuous casting of lead-clad tin composite material.

[0026] The outer diameter of the lead-clad tin metal composite rod is 12mm, and the thickness of the outer lead metal is 2mm. The upper and lower thermometers 1 and 5 use thermocouples to measure the temperature; The inner metal temperature control crucible 3, the upper temperature control crystallizer 12, the outer metal temperature control crucible 6 and the core metal liquid filling tube 9 are all made of No. 45 steel; the pressure of the control electromagnetic pump 11 is 0.03MPa, and the secondary cooling The device 15 is cooled by blowing at a speed of 3m / s; the temperature of the core metal temperature-controlled crucible 3 is controlled within the range from the freezing point of the corresponding metal or alloy to 100°C above the freezing point; the temperature of the outer metal temperature-controlled crucible 6 is controlled at Corresponding to the range from the s...

Embodiment approach 2

[0028] Electromagnetic ejection core filling continuous casting of copper clad aluminum composite material.

[0029] The outer diameter of the copper-clad aluminum metal composite rod is 12mm, and the thickness of the outer copper metal is 3mm. The upper and lower thermometers 1 and 5 use thermocouples to measure the temperature; the core metal temperature control furnace 4 adopts resistance heating, and the outer metal temperature control furnace 7 Induction heating is adopted; the core metal temperature control crucible 3, the outer metal temperature control crucible 6 and the core metal liquid filling core tube 9 are all made of graphite; the upper temperature control mold 12 is made of water-cooled metal mold lined with graphite The pressure of the electromagnetic pump 11 is controlled to be 0.04MPa, the secondary cooling device 15 adopts air blowing cooling, and its speed is 4m / s, and the temperature of the core metal temperature-controlled crucible 3 is controlled from th...

Embodiment approach 3

[0031] Electromagnetic ejection core filling continuous casting of stainless steel clad iron composite material.

[0032] The outer diameter of the stainless steel / iron metal composite rod is 12mm, and the thickness of the outer stainless steel metal is 3mm. The upper and lower thermometers 1 and 5 adopt infrared temperature measurement; the core metal temperature control furnace and the outer metal temperature control furnace adopt induction heating; the core metal temperature control crucible 3 is made of graphite; the outer metal temperature control crucible 6 It is made of magnesium oxide refractory material; the core liquid metal filling tube 9 is made of ZrO 2 Made of ceramics; the upper temperature control crystallizer 12 is made of water-cooled copper metal crystallizer; the secondary cooling device 15 is cooled by water spray; its speed is 5m / s, the pressure of the control electromagnetic pump 11 is 0.1MPa, and the core metal control The temperature of the warm cruci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com